Heat supply system and method for hydrogen production by methanol reforming

A technology for reforming hydrogen production and heating systems, applied in chemical instruments and methods, hydrogen, hydrogen/synthesis gas production, etc., can solve the problems of difficult temperature control, cracking, deterioration, and difficulty in integration of heat transfer oil. Save installation and operation and maintenance costs, improve heating and temperature control effects, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations.

[0050] In order to make the drawing concise, each drawing only schematically shows the parts related to the present invention, and they do not represent the actual structure of the product.

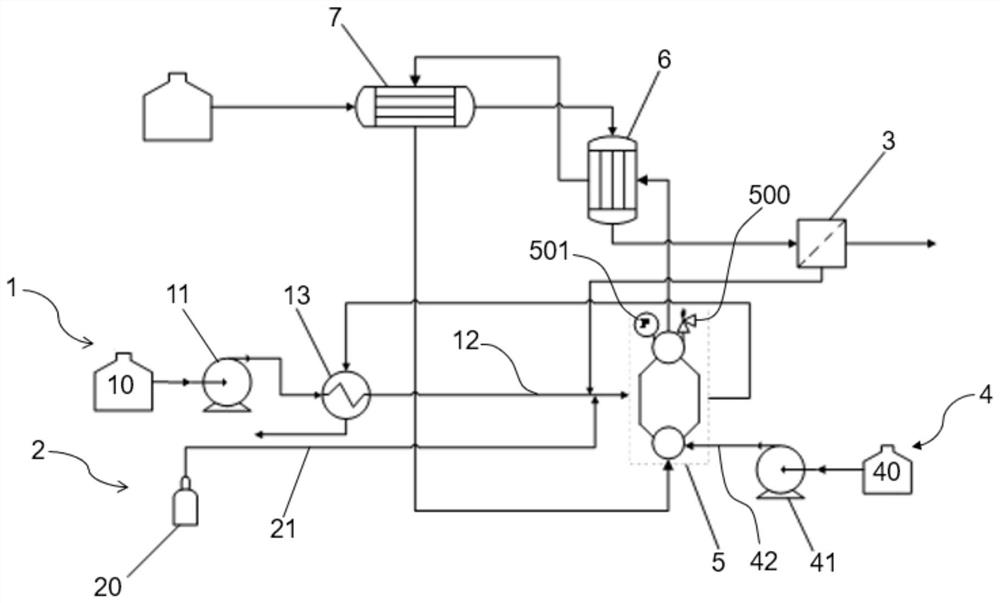

[0051] According to an embodiment provided by the present invention, combined with figure 1 As shown, a heating system for methanol reforming hydrogen production, including:

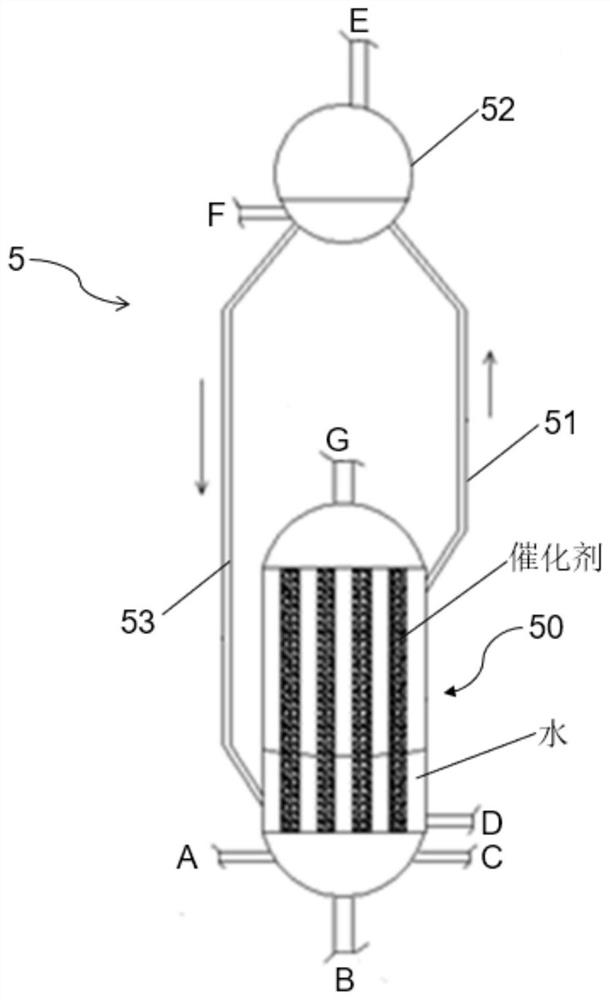

[0052] The water vapor generating device 5 is used for heating liquid water and separating saturated water vapor;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com