Combined pretreatment method for synergically degrading straw cellulose through compound florae and producing hydrogen through fermentation

A technology of straw cellulose and composite flora, which is applied in the direction of fermentation, can solve the problems of resource waste and environmental pollution, and achieve the effect of improving hydrogen production rate and straw degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

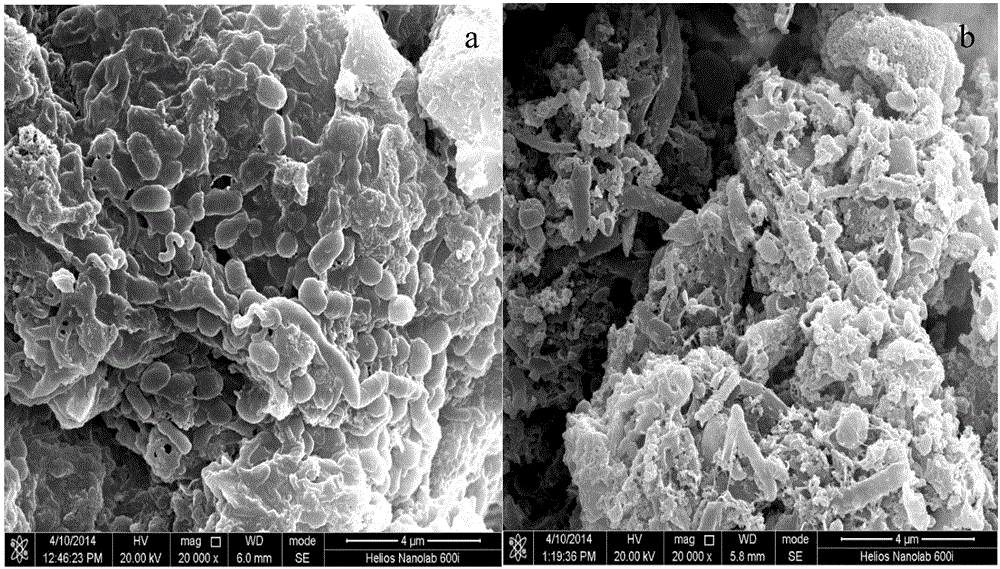

[0026] Example 1 Combined pretreatment method of compound bacterial flora synergistically degrading straw cellulose and fermenting hydrogen production

[0027] Methods as below:

[0028] 1) Corn stalk crushing

[0029] Corn stalks were obtained from the suburbs of Shenyang City. The corn stalks are cut into small sections of 3-5 cm, and then these small sections are pulverized into powders of 30-60 meshes by using a miniature plant pulverizer to obtain straw powder.

[0030] 2) Combined pretreatment of corn stalks

[0031] According to the solid-to-liquid ratio of 1:10 (g / ml), straw powder and 1.0% NaOH solution were taken, soaked at room temperature for 24 hours, washed with water until neutral, and dried at 80°C.

[0032] According to the solid-liquid ratio of 1:10 (g / ml), take the straw powder pretreated by NaOH solution and the sulfuric acid aqueous solution with a concentration of 1% by volume, put them in a container, and mix them evenly. Seal the container, put it i...

Embodiment 2

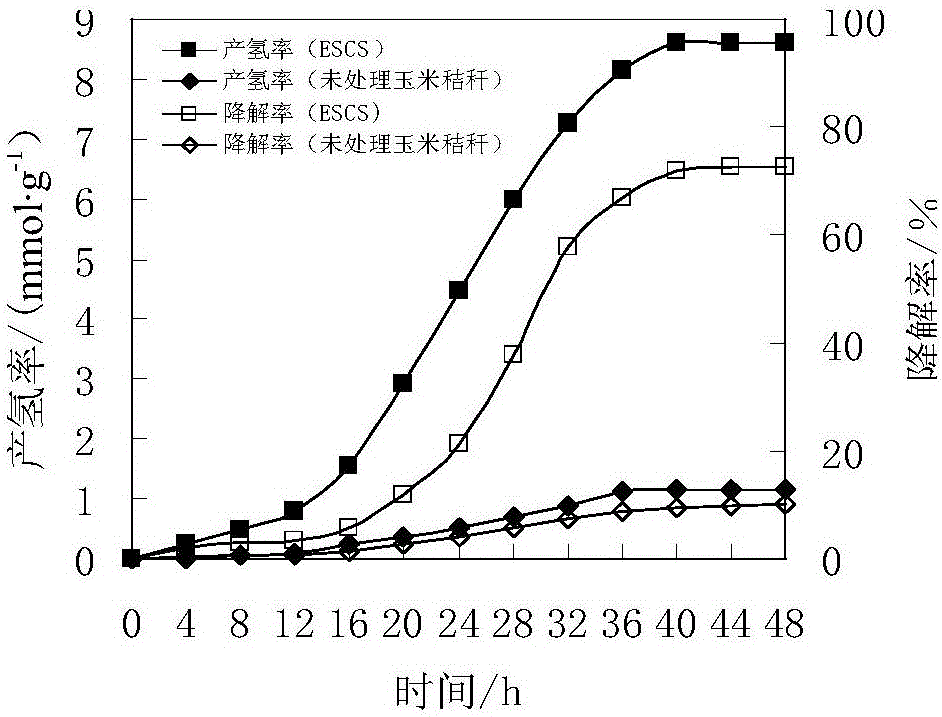

[0036] The comparative experiment of embodiment 2 pretreatment method

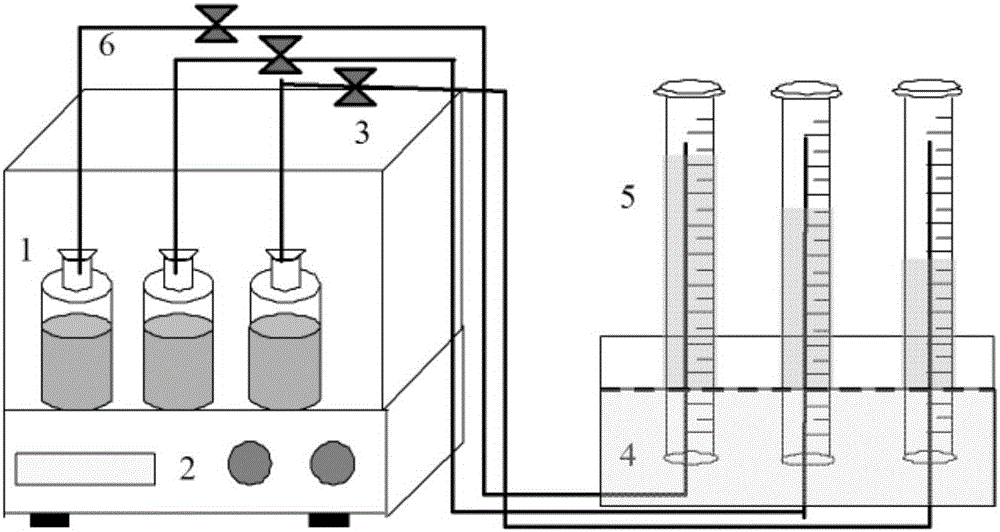

[0037] The method steps are the same as in Example 1, except that the pretreatment method in step 2) is changed. use as figure 2 In the device shown, different serum bottles 1 use different pretreated straw substrates. Specifically:

[0038] A: In Example 1, combined pretreatment of corn stalk powder (ESCS) with sodium hydroxide and acidified steam explosion combined pretreatment.

[0039] B: Sulfuric acid pretreatment: respectively prepare H with a volume percentage concentration of 0.2%, 0.5%, and 1.0%. 2 SO 4 solution with a solid-to-liquid ratio of 1:10, soaked at room temperature for 24 hours; the treated corn stalks were washed with water until neutral, and then dried at 80°C to obtain pretreated corn stalk powder that was pretreated with sulfuric acid alone.

[0040] C: Sodium hydroxide pretreatment: prepare NaOH solutions with a mass percent concentration of 0.5%, 1.0%, and 2.0%, respectively...

Embodiment 3

[0057] The screening of embodiment 3 compound bacterial strains

[0058] The strains used were taken from the activated sludge in the laboratory continuous flow stirred tank anaerobic fermentation hydrogen production reactor CSTR (ZL92114474.1). After separation and purification, 125 strains of hydrogen-producing bacteria were obtained, and the hydrogen-producing ability and fermentation end products of seven strains of hydrogen-producing bacteria B2, B19, H7, X9, X12, C3 and C17 with strong hydrogen-producing ability were analyzed by gas chromatography. According to optical microscope observation and gas chromatography analysis of end products, the isolated hydrogen-producing bacteria are divided into two types, the first type is ethanol-type fermentation hydrogen-producing strains B2, B19 and H7, etc.; the second type is butyric acid-type fermentation hydrogen production Bacteria X9, X12, C3 and C17 etc. The above seven hydrogen-producing bacteria were screened for the comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com