Methanol catalytically reforming hydrogen producing apparatus utilizing afterheat of internal combustion engine and its control method

A technology for catalytic reforming and hydrogen production devices, applied in chemical instruments and methods, inorganic chemistry, hydrogen and other directions, can solve the problems of low methanol conversion rate, low hydrogen production rate, limited catalyst coating area, etc., and achieve methanol conversion rate. The effect of high and high hydrogen production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific implementation examples

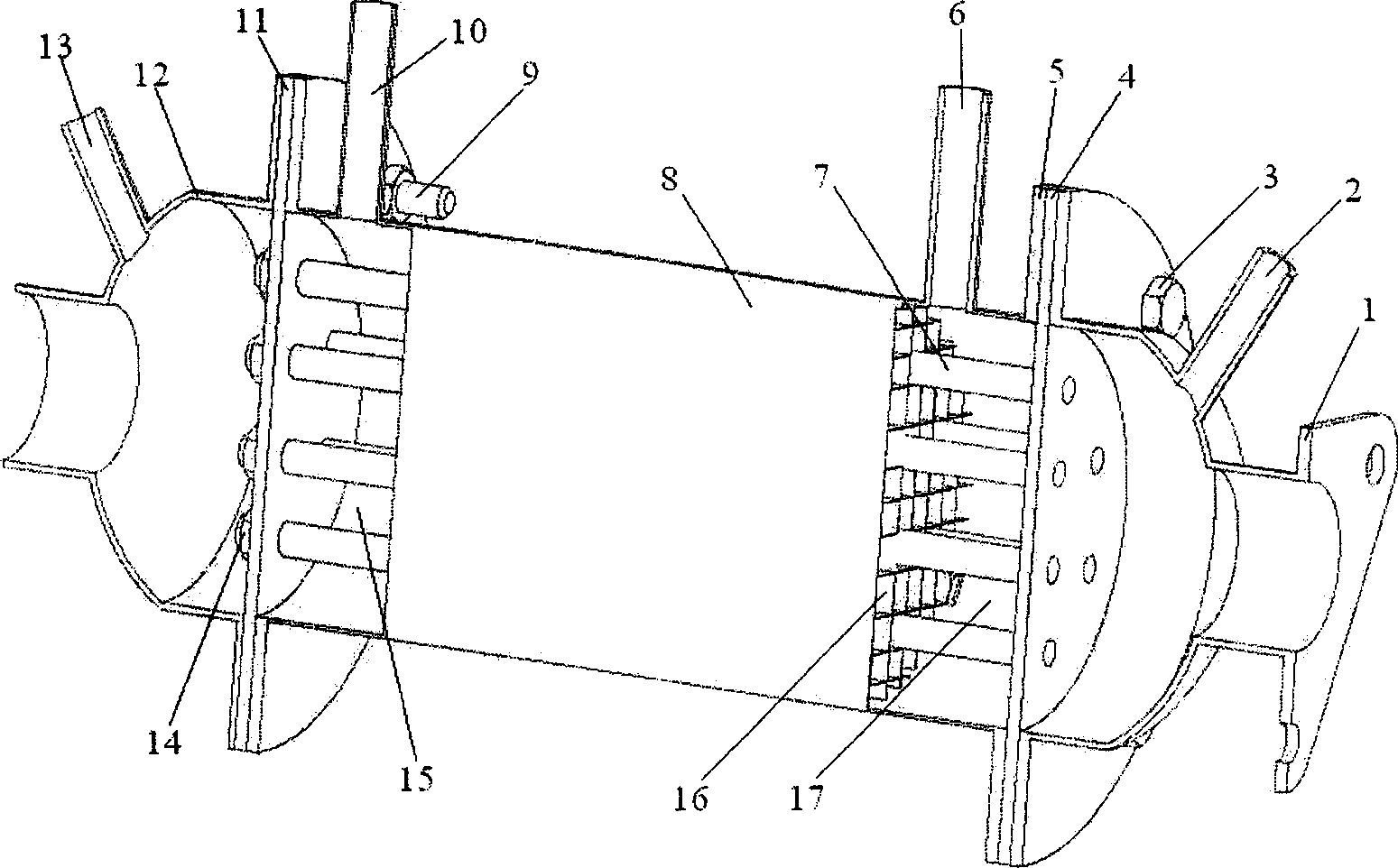

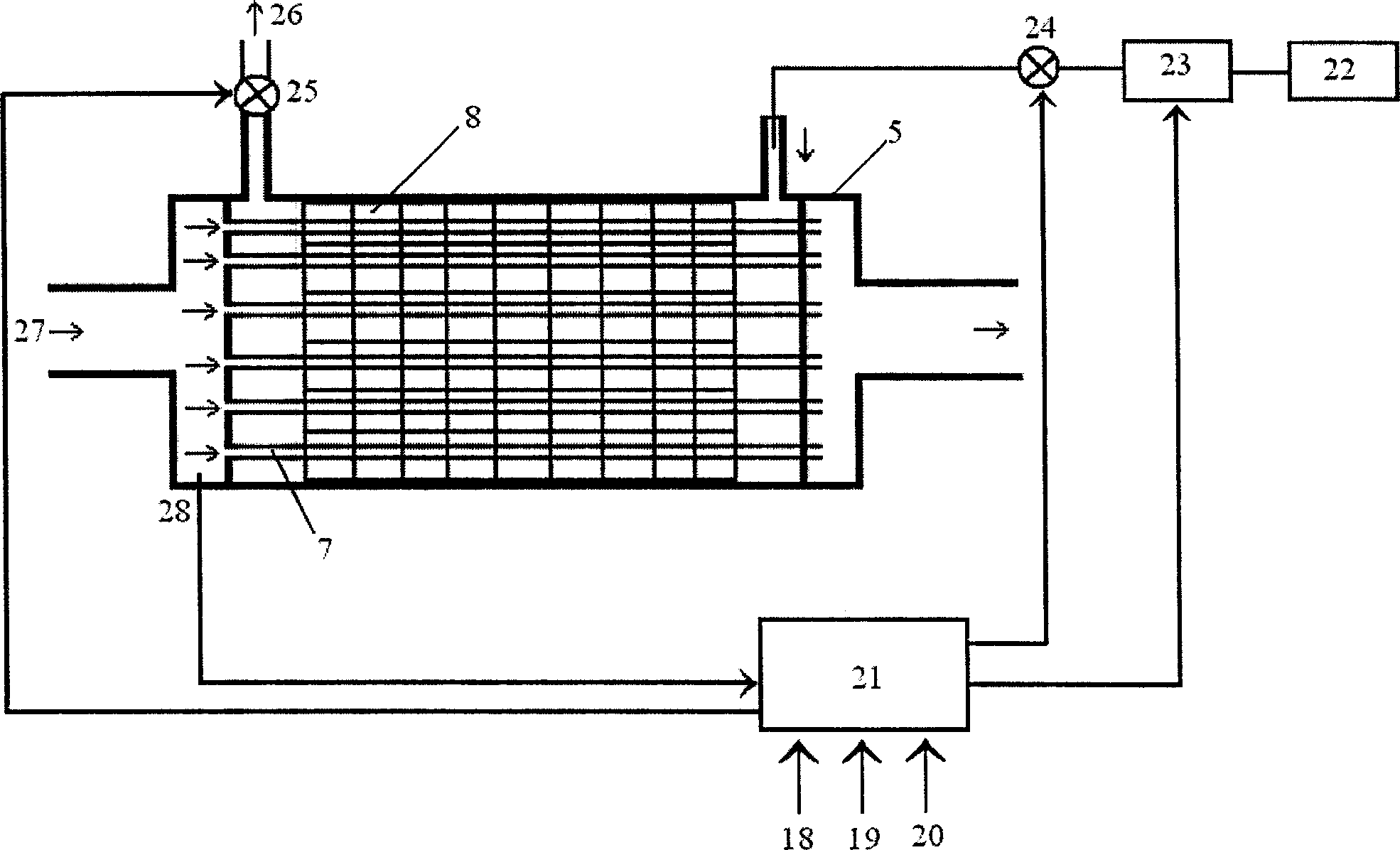

[0023] Combine below figure 1 , figure 2 Specific examples of the present invention will be described. The front end cover 1 of the reformer is connected to the reformer shell 5 through the front fastening screw 3 , and the front end plate 4 of the heat exchanger is arranged between the front end cover 1 and the reformer shell 5 . The reformer housing 5 is connected with the rear end plate 11 of the heat exchanger and the rear end cover 12 of the reformer through rear fastening screws 9 . The heat exchange tube 7 passes through the porous honeycomb ceramic 8 , one end of the heat exchange tube 7 is welded to the front end plate 4 of the heat exchanger, and the other end is fastened and sealed with the rear end plate 11 of the heat exchanger by a fastening nut 14 . The methanol aqueous solution enters the methanol aqueous solution gasification chamber 17 through the methanol aqueous solution inlet 6 on the reformer shell 5, and is v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com