La-Cu-Mn series oxygen storage-oxygen release material as well as preparation method and application thereof

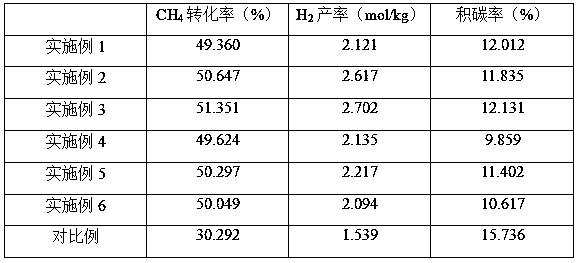

A la-cu-mn, oxygen storage technology, applied in the field of materials, can solve problems such as poor conversion rate and thermal stability, and achieve the effects of good carbon deposition resistance, high hydrogen production rate, and high CH4 conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: In this example, the La-Cu-Mn series oxygen storage-oxygen release material is La 0.8 Cu 0.2 MnO 3-δ , where 0<δ<3;

[0018] The preparation method of La-Cu-Mn series oxygen storage-oxygen release material, comprises the following steps:

[0019] (1) Add lanthanum nitrate, copper nitrate, manganese nitrate and citric acid to deionized water to obtain mixed solution A; the molar ratio of lanthanum nitrate, copper nitrate, manganese nitrate and citric acid is 0.8:0.2:1:0.1, mix The concentration of manganese nitrate in solution A is 0.1mol / L;

[0020] (2) Stir the mixed solution A obtained in step (1) at a temperature of 30°C for 10 hours to obtain sol B;

[0021] (3) The sol B obtained in step (2) was subjected to constant temperature treatment at 60°C for 36 hours to obtain gel C;

[0022] (4) Put the gel C at a temperature of 200°C for a high temperature and constant temperature calcination for 3.5 hours, and then place it at a temperature of 700°C for ...

Embodiment 2

[0023] Example 2: In this example, the La-Cu-Mn series oxygen storage-oxygen release material is La 0.3 Cu 0.7 MnO 3-δ , where 0<δ<3;

[0024] The preparation method of La-Cu-Mn series oxygen storage-oxygen release material, comprises the following steps:

[0025] (1) Add lanthanum nitrate, copper nitrate, manganese nitrate and citric acid to deionized water to obtain mixed solution A; the molar ratio of lanthanum nitrate, copper nitrate, manganese nitrate and citric acid is 0.3:0.7:1:10, mix The concentration of manganese nitrate in solution A is 2mol / L;

[0026] (2) Stir the mixed solution A obtained in step (1) at a temperature of 100°C for 1 hour to obtain sol B;

[0027] (3) The sol B obtained in step (2) was subjected to constant temperature treatment at 200°C for 8 hours to obtain gel C;

[0028] (4) Put the gel C at a temperature of 600°C for a high-temperature constant-temperature calcination for 1 hour, and then place it at a temperature of 1000°C for a second h...

Embodiment 3

[0029] Example 3: In this example, the La-Cu-Mn series oxygen storage-oxygen release material is La 0.7 Cu 0.3 MnO 3-δ , where 0<δ<3;

[0030] The preparation method of La-Cu-Mn series oxygen storage-oxygen release material, comprises the following steps:

[0031] (1) Add lanthanum nitrate, copper nitrate, manganese nitrate and citric acid to deionized water to obtain mixed solution A; the molar ratio of lanthanum nitrate, copper nitrate, manganese nitrate and citric acid is 0.7:0.3:1:8, mix The concentration of manganese nitrate in solution A is 1.6mol / L;

[0032] (2) Stir the mixed solution A obtained in step (1) at a temperature of 85°C for 2 hours to obtain sol B;

[0033] (3) The sol B obtained in step (2) was subjected to constant temperature treatment at 180°C for 12 hours to obtain gel C;

[0034] (4) Put the gel C at a temperature of 500°C for a high temperature and constant temperature calcination for 1.5 hours, and then place it at a temperature of 950°C for a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com