Safety rotary operator assembly

A technology of rotary operation and operator, applied in contact operating parts, parts of protection switches, operation/release mechanism of protection switches, etc., can solve the problems of easy damage and failure, complicated and expensive manufacturing, etc., to improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

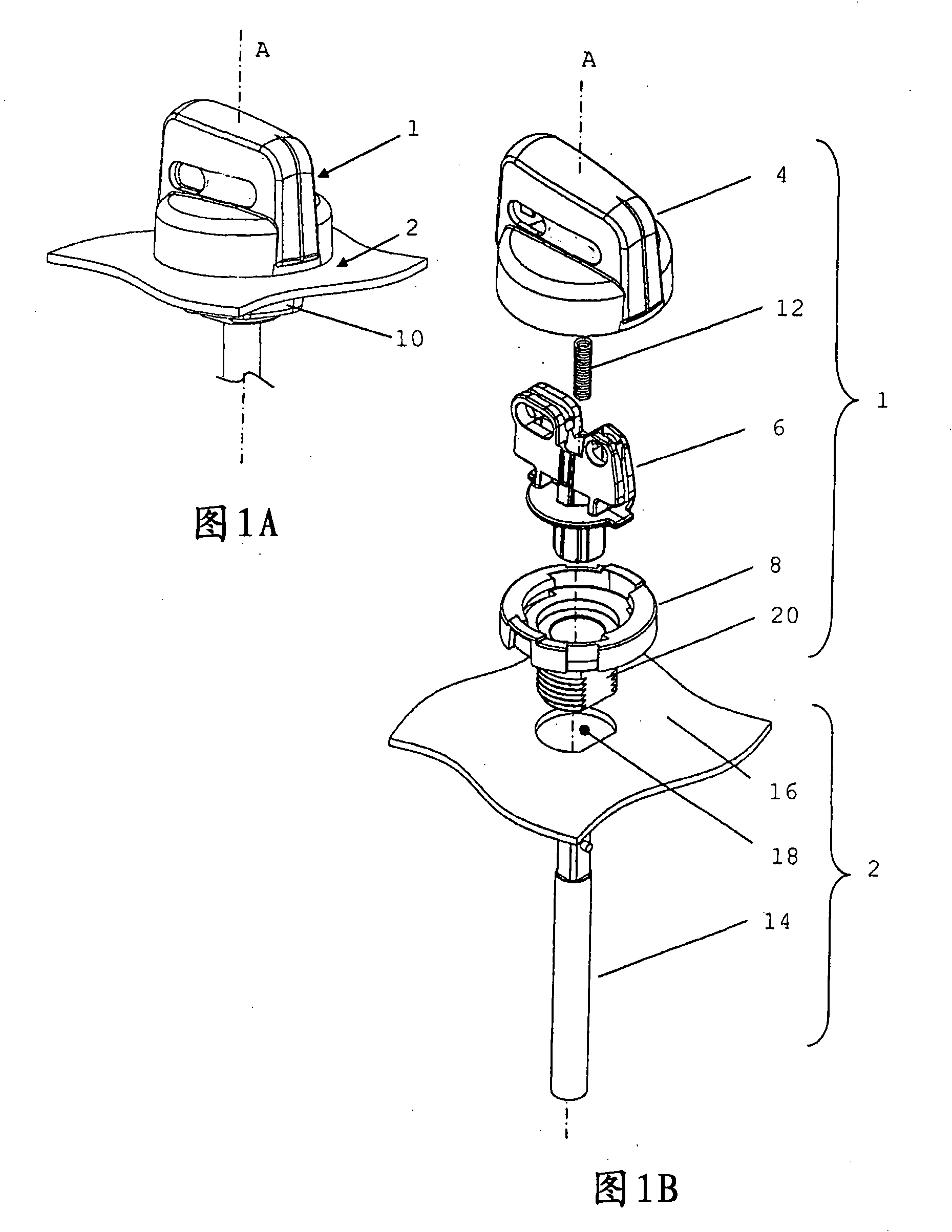

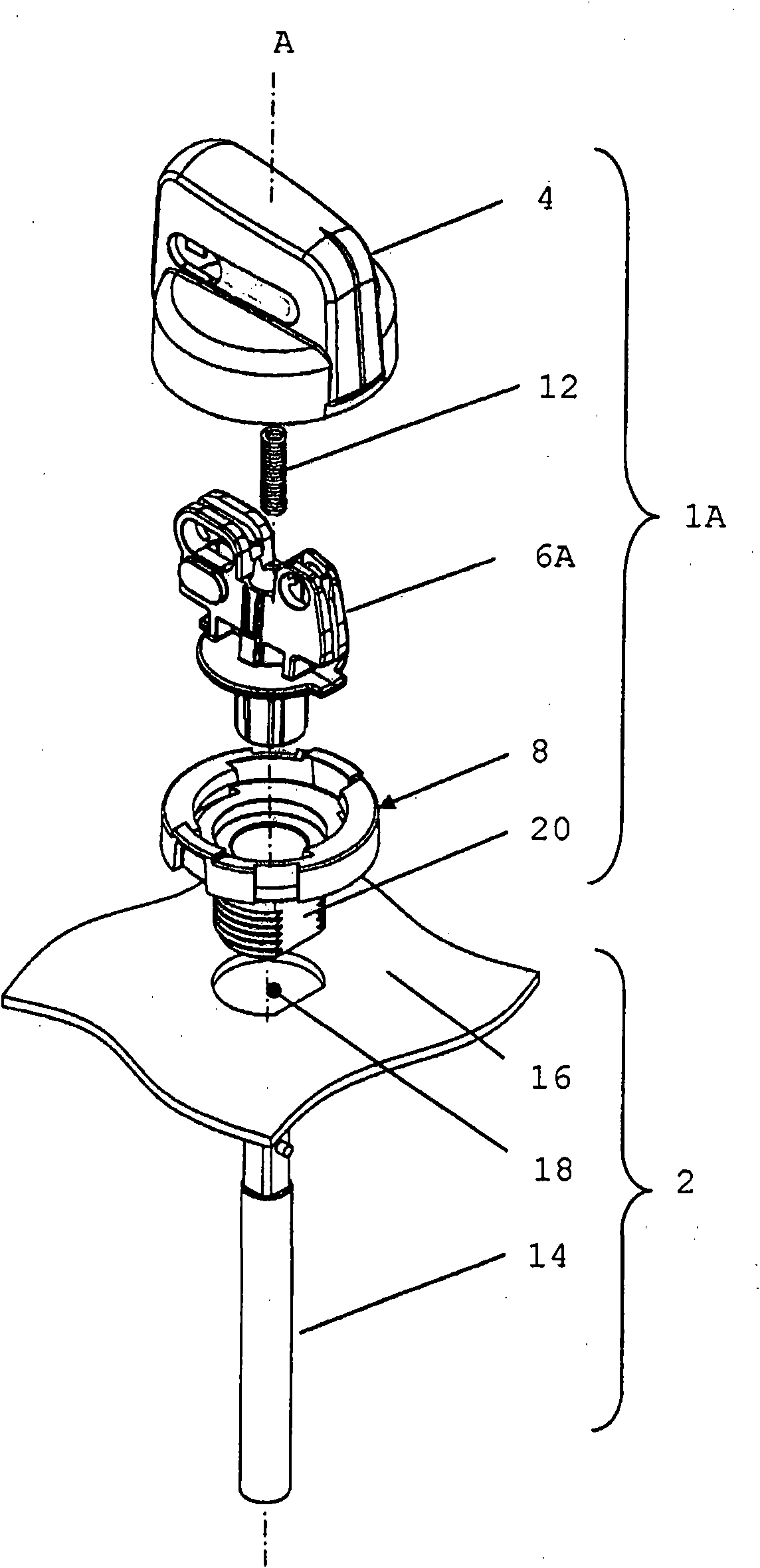

[0044] Figure 1A and 1B According to the assembled structure ( Figure 1A ) and by exploded view ( Figure 1B ) shows the rotary operator assembly 1 and a part of the switch 2. The rotary operator assembly 1 (or simply "assembly 1") includes a handle part 4 , a shaft part 6 , an operator body part 8 and a mounting nut 10 . A compression spring 12 is arranged between the handle part 4 and the shaft part 6 .

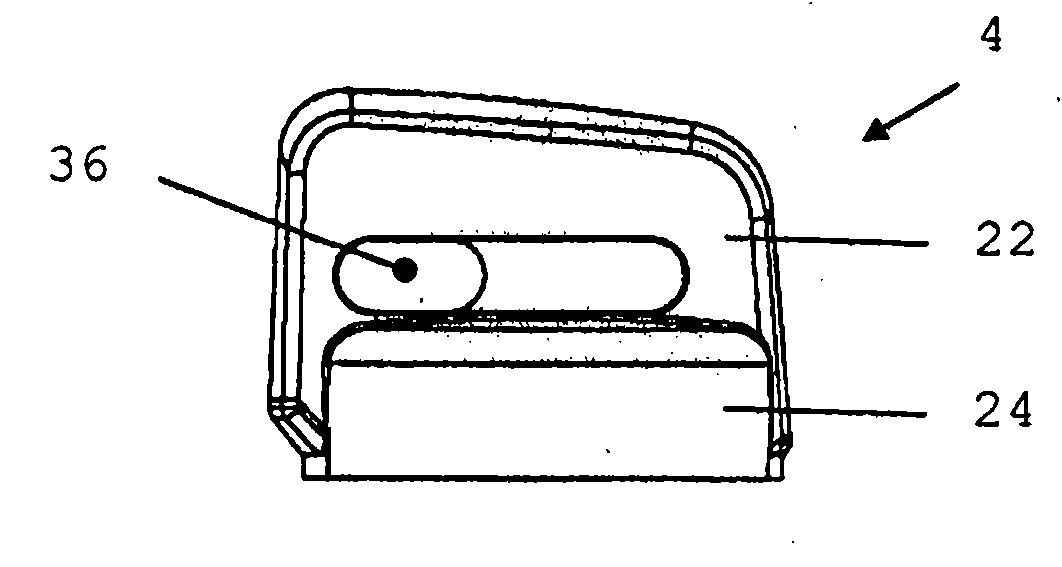

[0045] After forming the assembled structure of substantially closed assembly 1 ( Figure 1A ), the handle 4 is configured to receive and substantially cover the spring 12, a portion of the shaft member 6 and a portion of the operator body member 8.

[0046] The switch 2 includes a rotary shaft 14 and a housing 16 .

[0047] The shaft 14 is rotatable about an axis of rotation A relative to the housing 16 . The handle part 4 and the shaft part 6 are substantially rotatable about an axis of rotation A relative to the operator body part 8 (see below).

[0048] The op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com