Method for enhancing performance of ZrCo alloy to resist CO, CO2 and air poison and anti-pulverization performance of alloy

A technology of CO2 and alloy powder, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of poor anti-powdering ability, etc., and achieve the effect of enhancing viscosity, ensuring purity, good adhesion and wrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

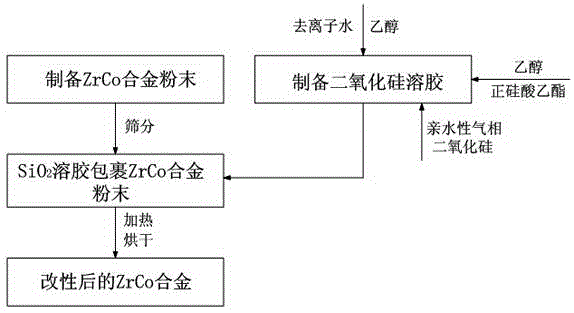

[0059] The invention is mainly used to modify the ZrCo alloy to enhance its resistance to CO and CO 2 , Air poisoning and anti-pulverization performance. Such as figure 1 As shown, the process flow of the present invention for modifying ZrCo alloy powder can be divided into several major steps: preparing ZrCo alloy powder, sieving ZrCo alloy powder, preparing silica sol, wrapping ZrCo alloy powder, and heating and drying. The implementation process is as follows:

[0060] Preparation of ZrCo alloy powder

[0061] The ZrCo alloy powder prepared by the process of the present invention and other processes of the present invention (especially the SiO 2 Sol), which can make ZrCo alloy resistant to CO, CO 2 , Air poisoning and anti-pulverization performance reach the best. The process of preparing ZrCo alloy powder in the present invention is as follows:

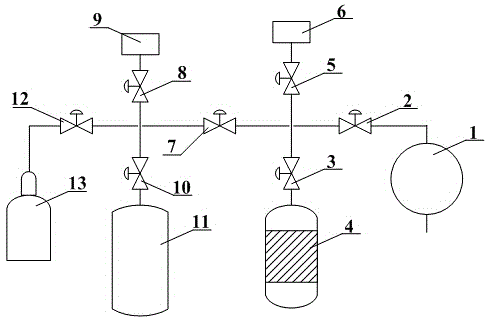

[0062] First, the ZrCo alloy particles are loaded into the chemical bed, and the chemical bed is connected to the hydrogen storage pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com