Positive electrode material for lithium sulfur battery, and lithium sulfur battery positive electrode

A positive electrode material and lithium-sulfur battery technology, applied in the field of lithium-sulfur battery positive electrode and lithium-sulfur battery positive electrode materials, can solve the problems of poor electronic conductivity and ion conductivity of elemental sulfur, poor cycle performance of lithium-sulfur batteries, volume expansion of sulfur electrodes, etc. , to achieve the effect of controllable fiber characteristics, rich material types, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

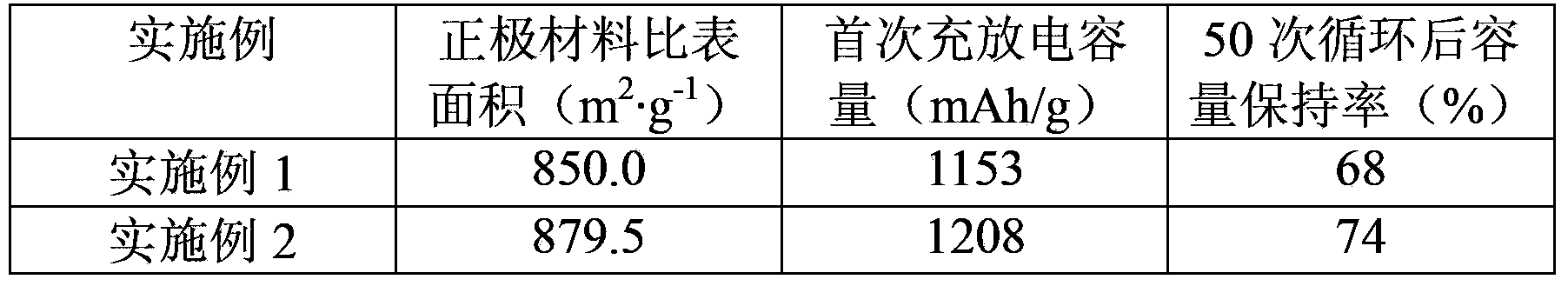

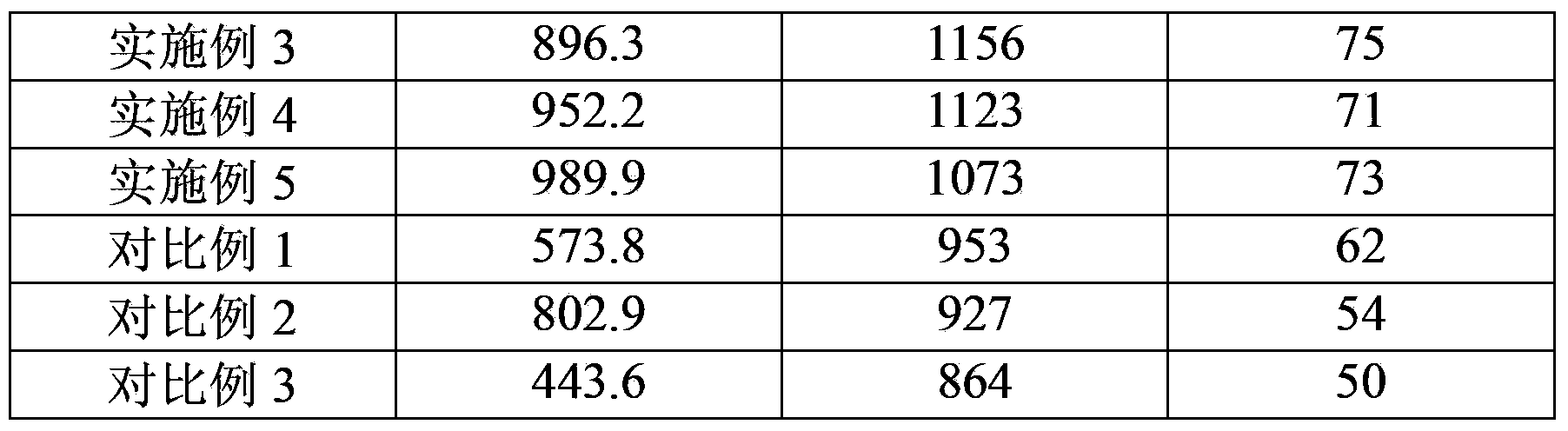

Embodiment 1

[0036] a Cut the aluminum foil, immerse it in the oxalic acid solution with a concentration of 5wt%, take it out after 4 hours, dry it at 70°C, wipe the surface of the metal foil with an anhydrous ethanol cotton ball, and dry it in the air;

[0037] b Preparation of graphene-doped mesoporous carbon hollow nanofibers: Coaxial electrospinning technology was used to prepare graphene-doped hollow nanofibers, and then the prepared hollow nanofibers were heat-treated to obtain mesoporous carbon hollow nanofibers ;

[0038] c Nanofiber sulfurization: place the prepared mesoporous carbon hollow nanofibers and elemental sulfur at both ends of the glass tube respectively, then put the glass tube into a tube furnace, feed in nitrogen, and heat at 500°C for 2h, Sulfur vapor diffuses and adsorbs in mesoporous carbon hollow nanofibers.

[0039]d (4) Preparation of slurry: Stir and mix the prepared sulfur-nanofiber composite material, polyvinylidene fluoride (PVDF), and N-methyl-2-pyrrolido...

Embodiment 2

[0045] a Cut the aluminum foil, immerse it in the oxalic acid solution with a concentration of 5wt%, take it out after 4 hours, dry it at 70°C, wipe the surface of the metal foil with an anhydrous ethanol cotton ball, and dry it in the air;

[0046] b Preparation of graphene-doped mesoporous carbon hollow nanofibers: Coaxial electrospinning technology was used to prepare graphene-doped hollow nanofibers, and then the prepared hollow nanofibers were heat-treated to obtain mesoporous carbon hollow nanofibers ;

[0047] c Nanofiber sulfurization: place the prepared mesoporous carbon hollow nanofibers and elemental sulfur at both ends of the glass tube respectively, then put the glass tube into a tube furnace, feed in nitrogen, and heat at 500°C for 2h, Sulfur vapor diffuses and adsorbs in mesoporous carbon hollow nanofibers.

[0048] d (4) Preparation of slurry: Stir and mix the prepared sulfur-nanofiber composite material, polyvinylidene fluoride (PVDF), and N-methyl-2-pyrrolid...

Embodiment 3

[0054] a Cut the aluminum foil, immerse it in the oxalic acid solution with a concentration of 5wt%, take it out after 4 hours, dry it at 70°C, wipe the surface of the metal foil with an anhydrous ethanol cotton ball, and dry it in the air;

[0055] b Preparation of graphene-doped mesoporous carbon hollow nanofibers: Coaxial electrospinning technology was used to prepare graphene-doped hollow nanofibers, and then the prepared hollow nanofibers were heat-treated to obtain mesoporous carbon hollow nanofibers ;

[0056] c Nanofiber sulfurization: place the prepared mesoporous carbon hollow nanofibers and elemental sulfur at both ends of the glass tube respectively, then put the glass tube into a tube furnace, feed in nitrogen, and heat at 500°C for 2h, Sulfur vapor diffuses and adsorbs in mesoporous carbon hollow nanofibers.

[0057] d Preparation of slurry: Stir and mix the prepared sulfur-nanofiber composite material, polyvinylidene fluoride (PVDF), and N-methyl-2-pyrrolidone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com