Moulding assembly and method for producing a syringe body

A manufacturing method, technology of syringes, applied in the field of molded components and manufacturing for the manufacture of syringe bodies, capable of solving problems of deformation, loss of tightness, penetration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

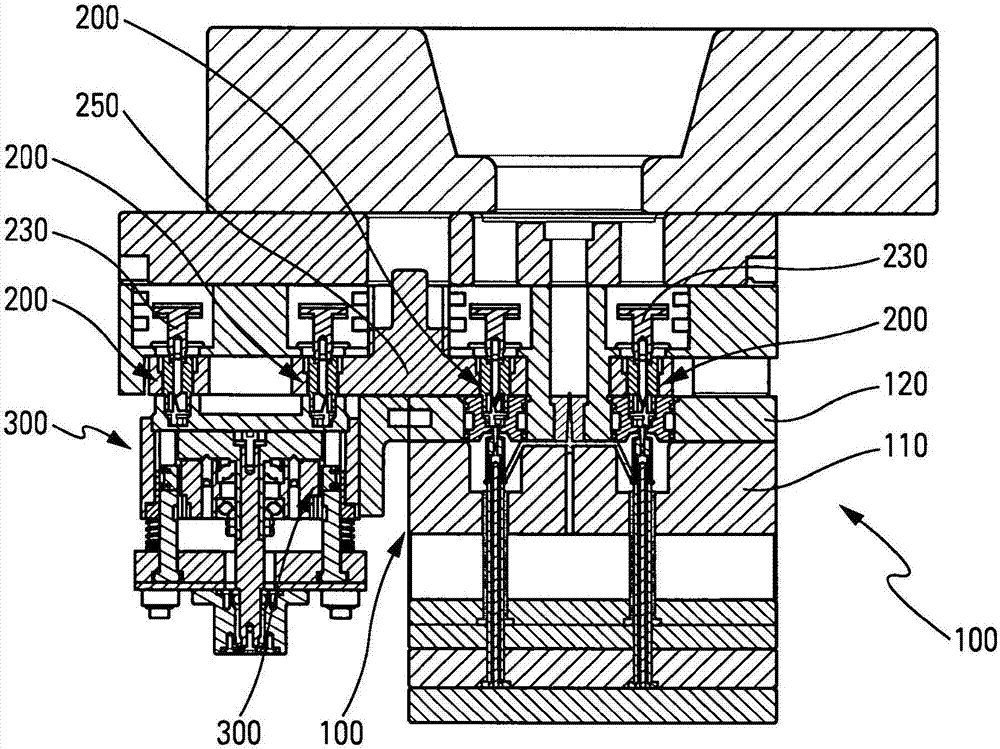

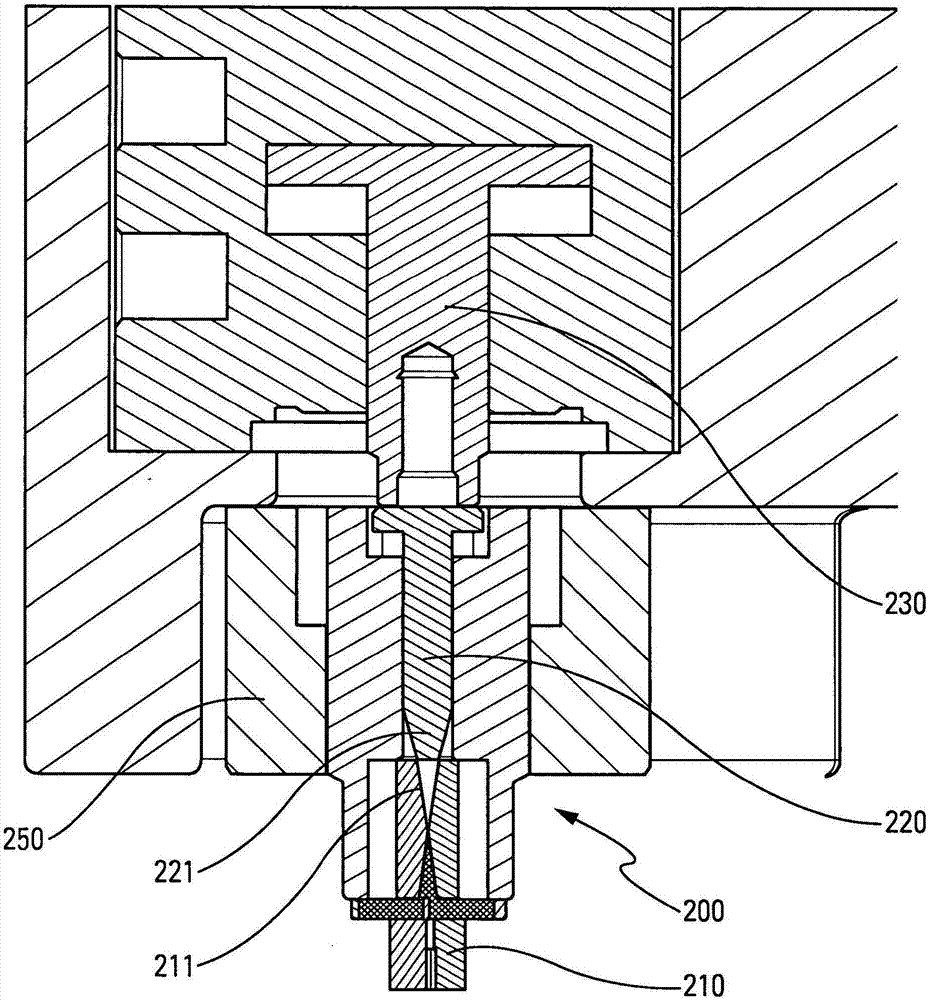

[0059] In the following description, the terms "axial", "radial" and "transverse" all refer to the longitudinal axis of the needle in the model element, i.e. Figure 1B with Figure 2-10 vertical axis in . The terms "proximal" and "distal" both refer to the needle.

[0060] The invention relates more particularly to the manufacture of a syringe body 10 provided with a needle 20 comprising a cylindrical portion 11 forming a reservoir and a hub portion 12 on which said needle 20 is fixed.

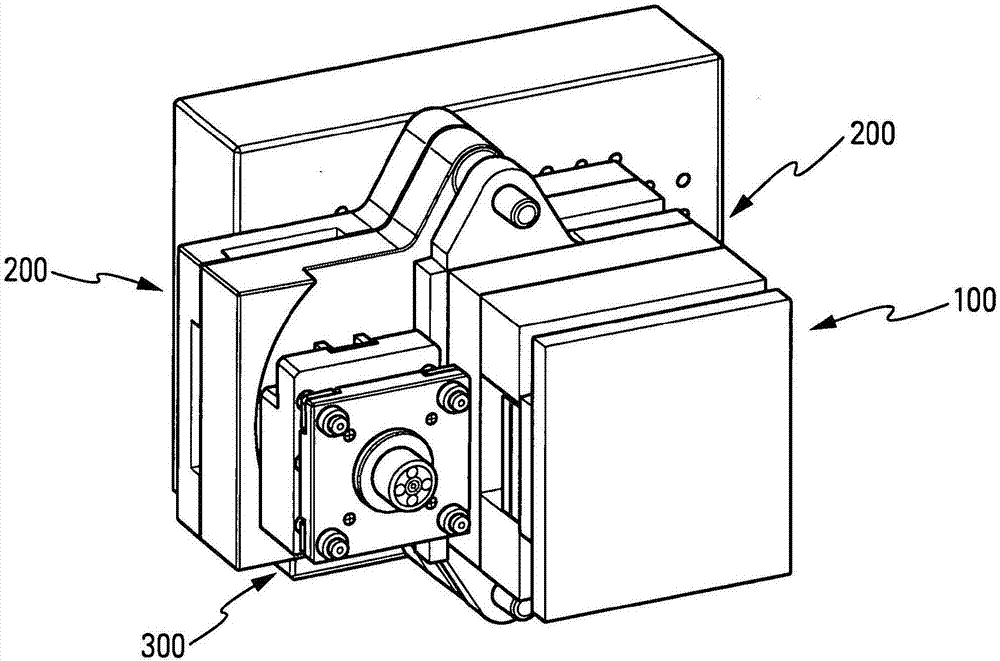

[0061] The invention will be described below with reference to the complete cycle of the molding assembly and with reference to the molding of the syringe body 10 onto the needle 20 . Of course, a molded assembly may include multiple subassemblies that work simultaneously.

[0062] The molding assembly comprises at least one mold unit 100, each mold unit 100 comprising a first mold part 110 and a second mold part 120 axially movable relative to said first mold part 110 between an open posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com