Preparation method for rolled magnesium-aluminum laminated plate prefabricated blank

A technology of laminated plates and prefabricated blanks, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of affecting the utilization rate of composite raw materials at the interface, prone to oxidation of the surface to be composited, and affecting the interface bonding effect, etc., to achieve improved Deformation coordination and plate utilization, bimetal interface is straight and uniform, and the effect of good plate shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

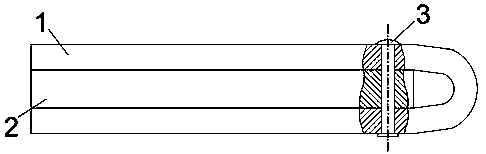

[0021] Such as figure 1 , as shown in 2, the material selection is a 1060 pure aluminum plate with a size of 220×80×2mm and an AZ31 magnesium alloy plate with a size of 100×80×3mm;

[0022] The specific implementation steps are:

[0023] 1. Put the above-mentioned AZ31 magnesium plate into the heating furnace and keep it warm for 0.5h at 300°C for annealing treatment;

[0024] 2. Put the above-mentioned pure aluminum plate into the heating furnace for heating, keep it at 350°C for 1 hour, and perform annealing treatment;

[0025] The superimposed surface of the above-mentioned annealed magnesium plate and aluminum plate is polished with 400 mesh, 600 mesh, and 800 mesh sandpaper respectively along the rolling width direction, and the oil stain is cleaned with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com