Connection method for reinforcing joints between pre-fabricated hollow slabs and horizontal beam by embedding steel reinforcements

A connection method and a technology of hollow slabs, which are applied in building reinforcements, structural elements, building components, etc., can solve unfavorable earthquake resistance and other problems, achieve improved collaborative deformation capabilities, reduce interstory displacement, and enhance tensile and shear bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] An embodiment of the present invention is further described below in conjunction with accompanying drawing:

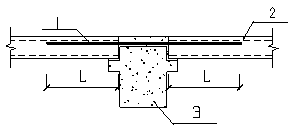

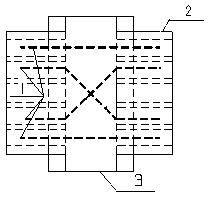

[0011] In the connection method between embedded steel bars and reinforced prefabricated hollow slabs and bay beam nodes of the present invention, at first two prefabricated hollow slabs 2 opposite to each other on both sides of the bay beam 3 are symmetrically provided with grooves with a length L of 500mm on the front and rear sides. The steel bars 1 that connect the two prefabricated hollow slabs 2 horizontally are respectively arranged inside, and then the steel bars 1 that are obliquely intersected in an X shape are arranged in the middle between the two prefabricated hollow slabs 2, and then between the two prefabricated hollow slabs 2 Fine stone concrete is poured on the middle bay beam 3 in the room, and finally a layer of 20mm thick fine stone concrete is applied at the joint between the prefabricated hollow slab and the bay beam; the diameter of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com