High-damping Mg-Zn-Ni-Y alloy and preparation process thereof

A high damping, alloy technology, applied in the field of high damping Mg-Zn-Ni-Y alloy and its preparation technology, can solve the problem that the damping performance has not been studied, and achieve convenient control of test parameters, easy operation and strong portability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

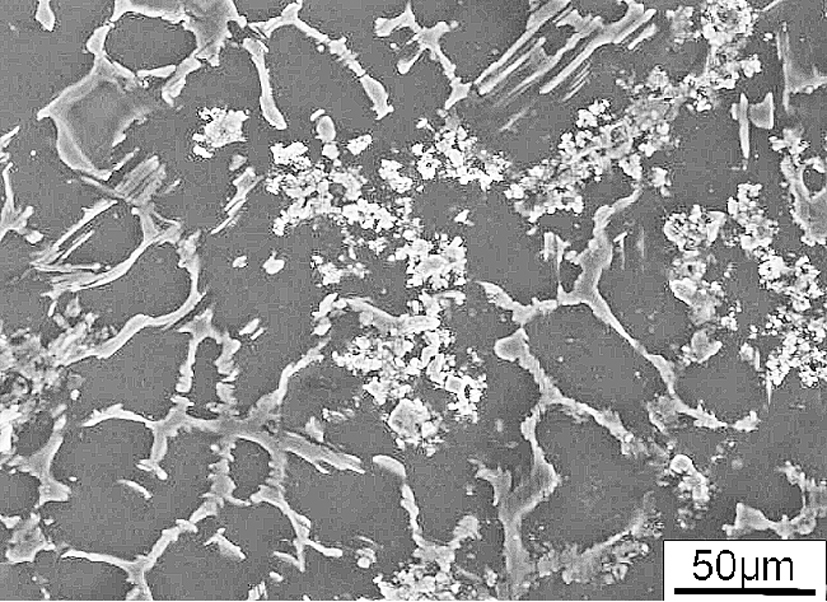

[0025] A high damping Mg-Zn-Ni-Y alloy, the composition and mass percentage of alloy elements are: Zn 3.5wt%, Ni3.2wt%, Y 12.7wt%, impurity element content is less than 0.1wt%, and the balance is magnesium ; Its microstructure features are: the main phase is composed of magnesium phase and long-period phase, and the grain boundary is parallel long-period phase.

[0026] A preparation process of high damping Mg-Zn-Ni-Y alloy, comprising the following steps:

[0027] S1. Weigh raw materials according to the mass percentage of alloy elements: Zn 3.5wt%, Ni 3.2wt%, Y 12.7wt%, impurity element content is less than 0.1wt%, and the balance is magnesium; wherein, Y and Ni elements are Mg-30Y The master alloy (640g) and Mg-25Ni master alloy (160g) are added to the electromagnetic induction melting furnace, and the Zn element is added to the electromagnetic induction melting furnace in the form of Zn particles (52.5g). Keep it warm at 770°C for 2 hours and stir it by electromagnetic in...

Embodiment 2

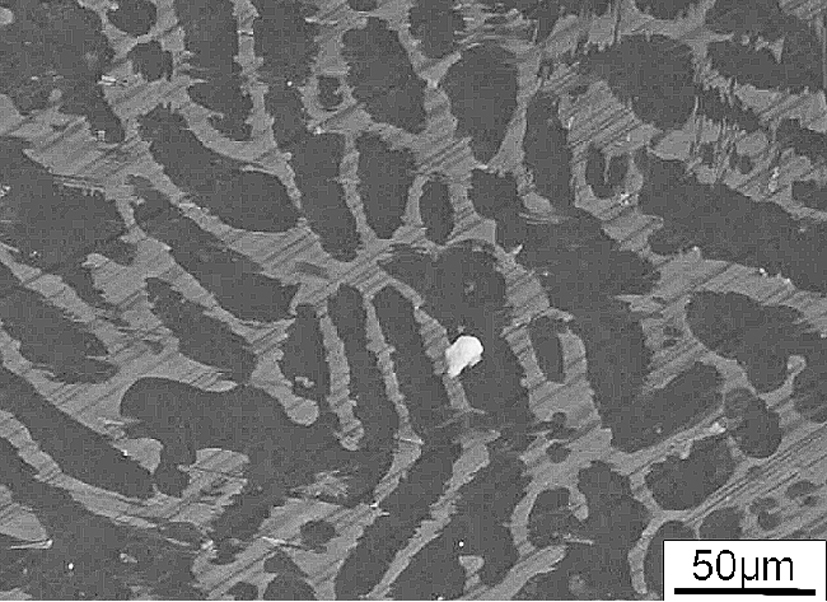

[0030] A high damping Mg-Zn-Ni-Y alloy, the composition and mass percentage of alloy elements are: Zn 1.28wt%, Ni1.16wt%, Y 4.68wt%, impurity element content is less than 0.1wt%, and the balance is magnesium ; Its microstructure features are: the main phase is composed of magnesium phase and long-period phase, and the grain boundary is parallel long-period phase.

[0031] A preparation process of high damping Mg-Zn-Ni-Y alloy, comprising the following steps:

[0032] S1. Weigh raw materials according to the mass percentage of alloy elements: Zn 1.28wt%, Ni 1.16wt%, Y 4.68wt%, impurity element content is less than 0.1wt%, and the balance is magnesium; wherein, Y and Ni elements are Mg-30Y The master alloy (640g) and Mg-25Ni master alloy (160g) are added to the electromagnetic induction melting furnace, and the Zn element is added to the electromagnetic induction melting furnace in the form of Zn particles (52.5g). Keep warm at 770°C for 4 hours and stir by electromagnetic indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com