A low-additive halogen-free flame-retardant polylactic acid composite material and preparation method thereof

A composite material and polylactic acid technology, which is applied in the field of low-additive halogen-free flame-retardant polylactic acid composite material and its preparation, and can solve the problems of environmental pollution, toxicity, and large addition amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

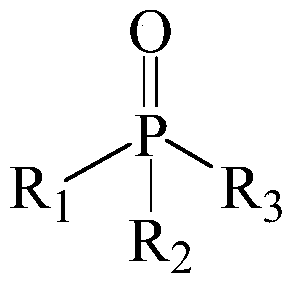

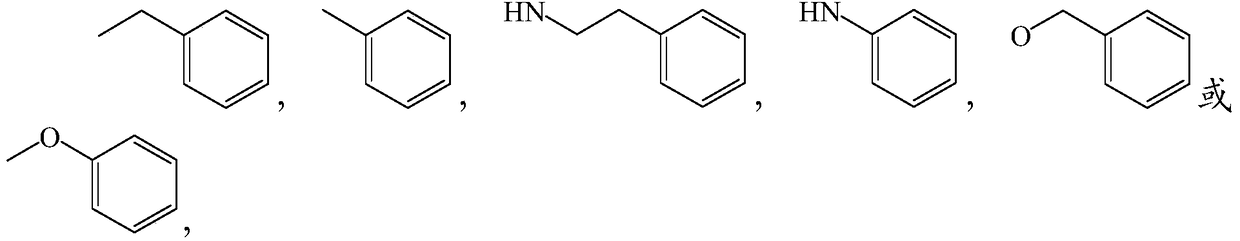

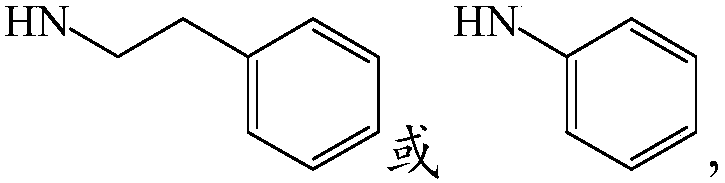

Method used

Image

Examples

experiment example 1

[0082] Experimental Example 1 Determination of Limiting Oxygen Index

[0083] According to the ASTM D2863-97 standard, the limiting oxygen index value of the material is obtained, which indicates the minimum oxygen content volume percentage required to maintain its combustion after the material is ignited in a mixed gas of oxygen and nitrogen. The higher the limiting oxygen index value, the higher the limit oxygen index value of the material The less combustible it is, the better the flame retardancy. It is generally believed that the limiting oxygen index is less than 22 and belongs to flammable materials, between 22 and 27 belongs to combustible materials, and greater than 27 belongs to flammable materials.

[0084] Experimental Example 2 Vertical Burning Test

[0085] According to the ASTM D3801 standard, the vertical burning level of the material is obtained, which is used to reflect the flame propagation performance of the material surface. According to a certain flame he...

experiment example 4

[0088] Experimental Example 4 Hardness Test

[0089] According to the nano-indentation technology ASTM E2546 standard to test and calculate, the hardness value of the material is obtained, which reflects the ability of the material surface to resist the intrusion of other harder objects. The larger the hardness value, the harder the material.

Embodiment 1

[0091] Embodiment 1 The preparation method of low-addition type halogen-free flame-retardant polylactic acid composite material

[0092]The polylactic acid was vacuum-dried at 80°C for 4 hours, and the dried polylactic acid, flame retardant, optional flame retardant additive, optional antioxidant and optional lubricant were placed in a high-speed mixer Stir evenly, put the above mixture in a twin-screw extruder for melt blending, and extrude to granulate. The temperature settings of each section of the twin-screw extruder are as follows: feed inlet 155°C, feed section 160°C, The compression section is 160°C, the metering section is 165°C, the adapter is 170°C, the die section is 165°C, the screw speed of the main engine is 190rpm, the conveying screw speed is 30rpm, the feeding speed of the barrel is 16s, and the extruded material is air-cooled and then air-dried and pelletized to obtain the low-addition halogen-free flame-retardant polylactic acid composite material in granul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com