Silicon wafer cleaning agent

A technology of silicon wafer cleaning agent and alkali agent, which is applied in the directions of detergent compounding agent, detergent composition, surface active detergent composition, etc., can solve the problems of surface corrosion of silicon wafer, appearance of spots, unsatisfactory cleaning effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

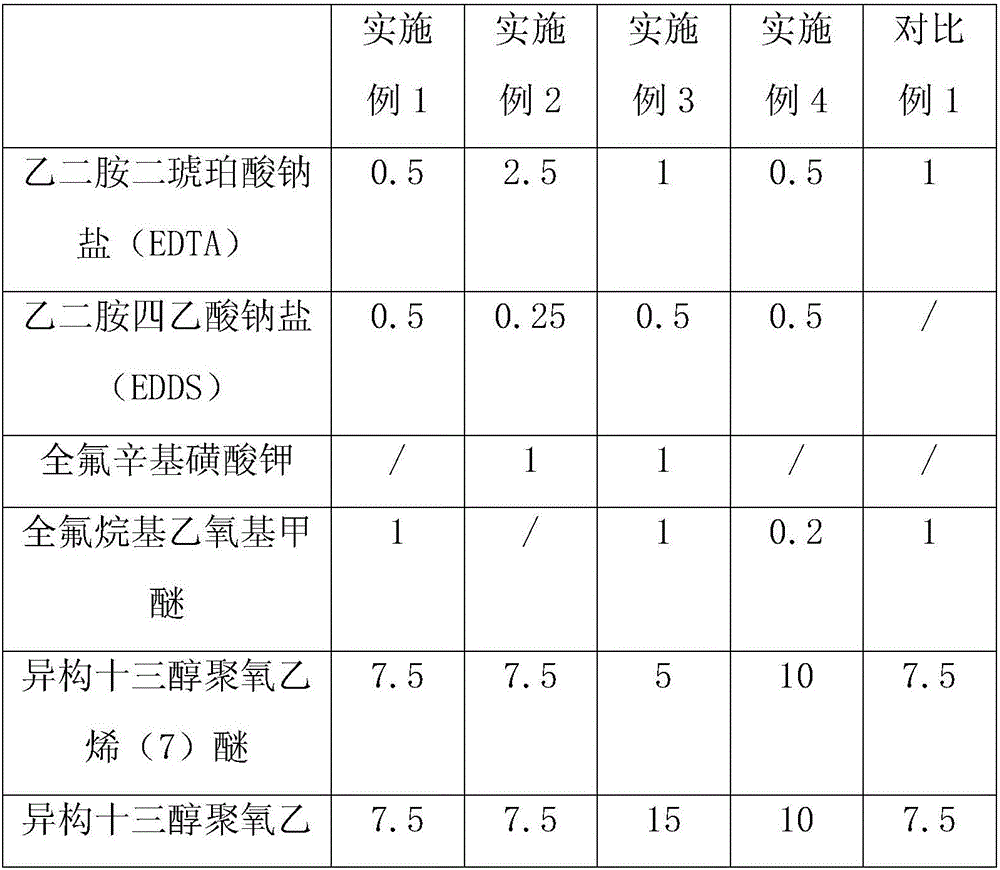

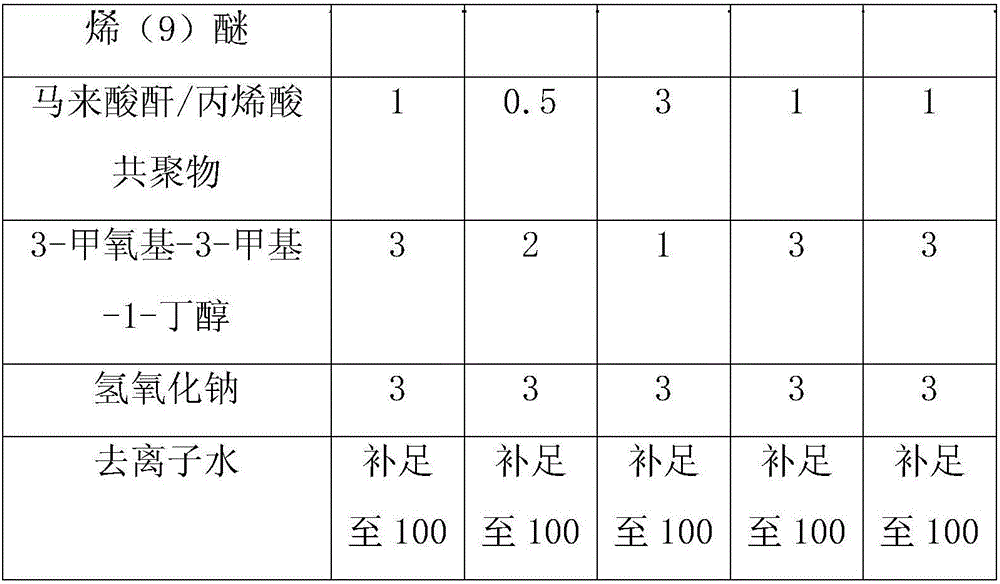

[0022] According to Table 1, add the raw materials into deionized water in sequence, raise the temperature to 40-50° C., stir evenly, and cool to room temperature to prepare the silicon wafer cleaning agent.

[0023] Table 1 silicon wafer cleaning agent formula (the numerical value in the table is the weight percent of this component)

[0024]

[0025]

[0026] Silicon wafers were cleaned in Examples 1-4 and Comparative Example 1 above. The specific cleaning method is as follows: add 10g of the cleaning agents of Examples 1-4 and Comparative Example 1 into a cleaning tank filled with 240g of deionized water, mix well, then immerse the silicon wafer in the cleaning tank, and the cleaning time is 50°C , the cleaning temperature is 480s.

[0027] The silicon wafers washed in Examples 1-4 are visually smooth, colorless, and have no obvious residual stains.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com