Water-based stainless steel cleaner

A cleaning agent and stainless steel technology, applied in the field of stainless steel cleaning agents, can solve the problems of not being widely applicable to stainless steel parts, etc., and achieve the effects of good degreasing and degreasing effects, good environmental protection performance, and simple use methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

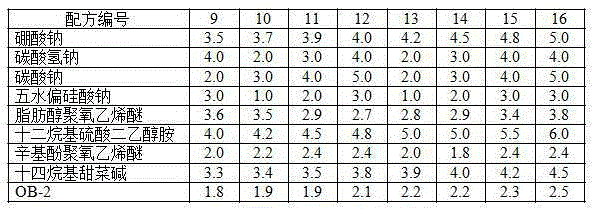

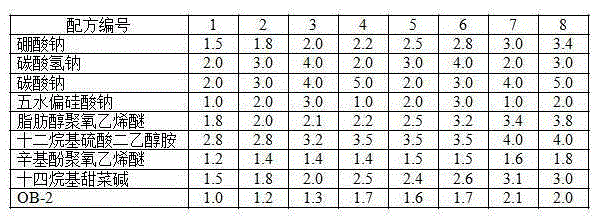

[0037] Embodiment formula is as follows:

[0038]

[0039]

[0040] The preparation method of above-mentioned embodiment is:

[0041] Mix the raw materials according to the ratio and stir evenly at 30°C, then let it stand for 1 hour, and adjust the pH value to 8-9 with 0.1% sulfuric acid solution or 0.1% sodium hydroxide solution to obtain the required stainless steel. agent. The stirring temperature depends on the formula. If the dissolution rate of the raw materials is slow, the stirring temperature can be increased appropriately, but the stirring temperature should not exceed 50°C. When the cleaning agent foams after stirring, the standing time can be extended appropriately, and then adjusted pH value.

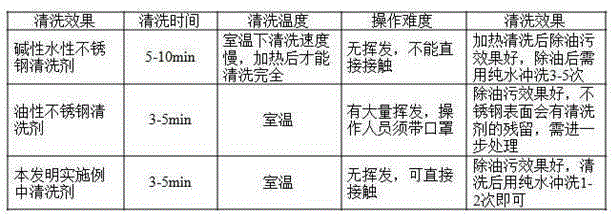

[0042] Cleaning effect comparison:

[0043] The commercially available alkaline water-based stainless steel cleaning agent and oily stainless steel cleaning agent were used for cleaning together with the above-mentioned examples, and were compared. Put the same di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com