Metal processing part grease cleaning agent, preparation method and application

A metal processing and grease cleaning technology, applied in the field of grease cleaning agent, to achieve the effects of good effect, low cleaning cost, safe and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

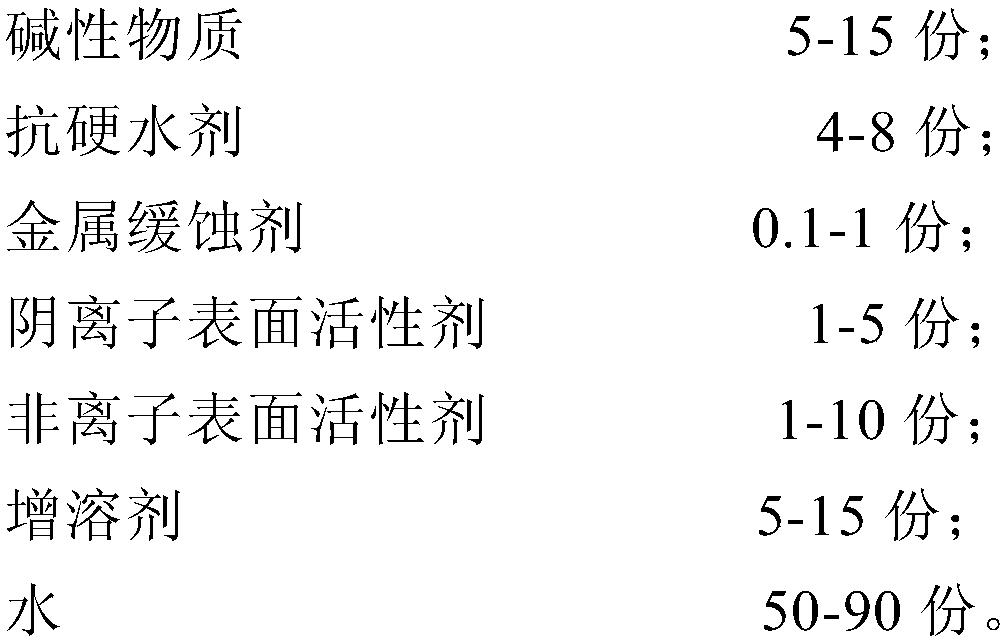

Method used

Image

Examples

Embodiment 1

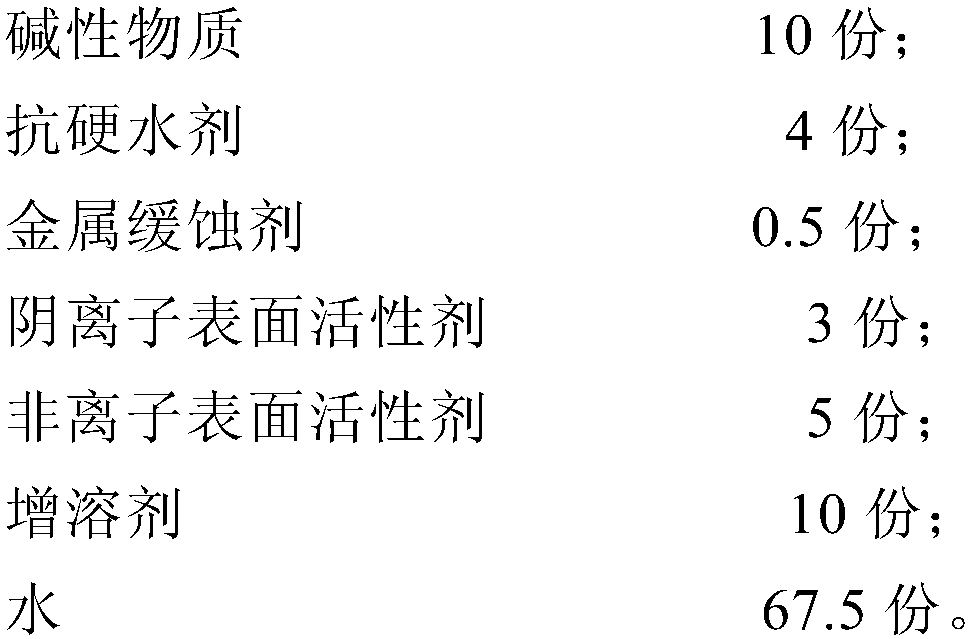

[0042] This embodiment discloses a grease cleaning agent for metal processing parts, which comprises the following components by weight:

[0043]

[0044] The alkaline substance is potassium hydroxide and ethanolamine, the anti-hard water agent is nitrilotriacetic acid NTA, ethylenediaminetetraacetic acid EDTA, the metal corrosion inhibitor is 2-mercaptobenzothiazole MBT, and the anionic surface The active agent is sodium fatty acid methyl ester sulfonate MES and disodium fatty alcohol polyoxyethylene ether succinate sulfonate AESS, and the nonionic surfactant is fatty alcohol polyoxyethylene ether.

[0045] The preparation method of the grease cleaning agent for metal processing parts of the present embodiment comprises the following steps:

[0046] Step 1. Mix water, alkaline substance, anti-hard water agent and metal corrosion inhibitor evenly;

[0047] Step 2, add anionic surfactant, nonionic surfactant, stir evenly;

[0048] Step 3. Add the solubilizer and stir evenl...

Embodiment 2

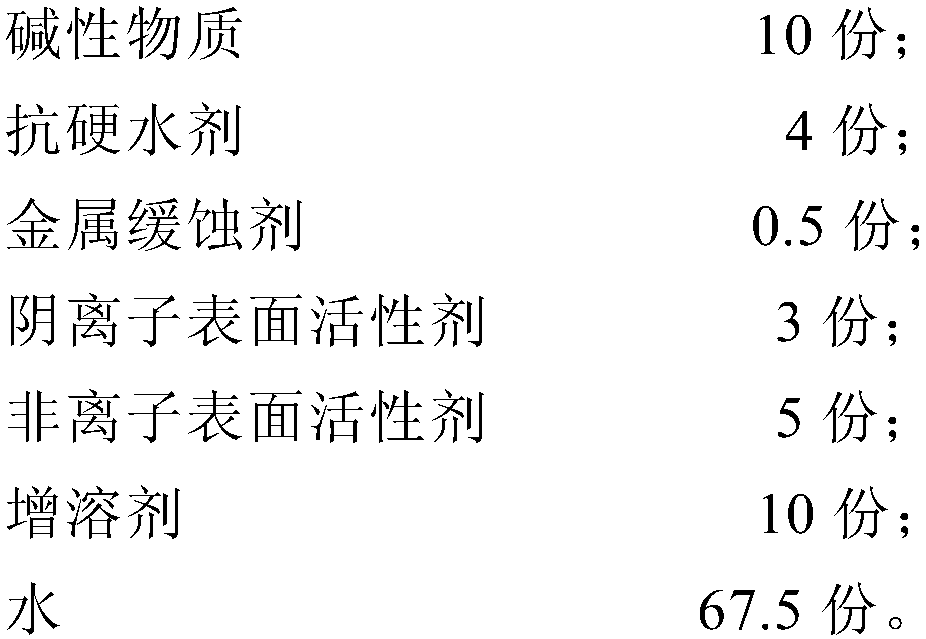

[0057] This embodiment discloses a grease cleaning agent for metal processing parts, which comprises the following components by weight:

[0058]

[0059] The alkaline substance is sodium metasilicate and sodium carbonate, the anti-hard water agent is aminotrimethylenephosphonic acid ATMP, diethylenetriaminepentamethylenephosphonic acid DTPMP, and the metal corrosion inhibitor is benzotriazepam Azole BTA, the anionic surfactant is sodium alkylbenzene sulfonate LAS and fatty alcohol polyoxyethylene ether succinate disodium sulfonate AESS, the nonionic surfactant is fatty acid methyl ester ethoxylate FFEE and Sorbitan Fatty Acid Ester.

[0060] The preparation method of the metal processing parts grease cleaning agent of the present embodiment comprises the following steps:

[0061] Step 1. Mix water, alkaline substance, anti-hard water agent and metal corrosion inhibitor evenly;

[0062] Step 2, add anionic surfactant, nonionic surfactant, stir evenly;

[0063] Step 3. Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com