Advanced treatment method for urban middle water as industrial recirculated cooling water

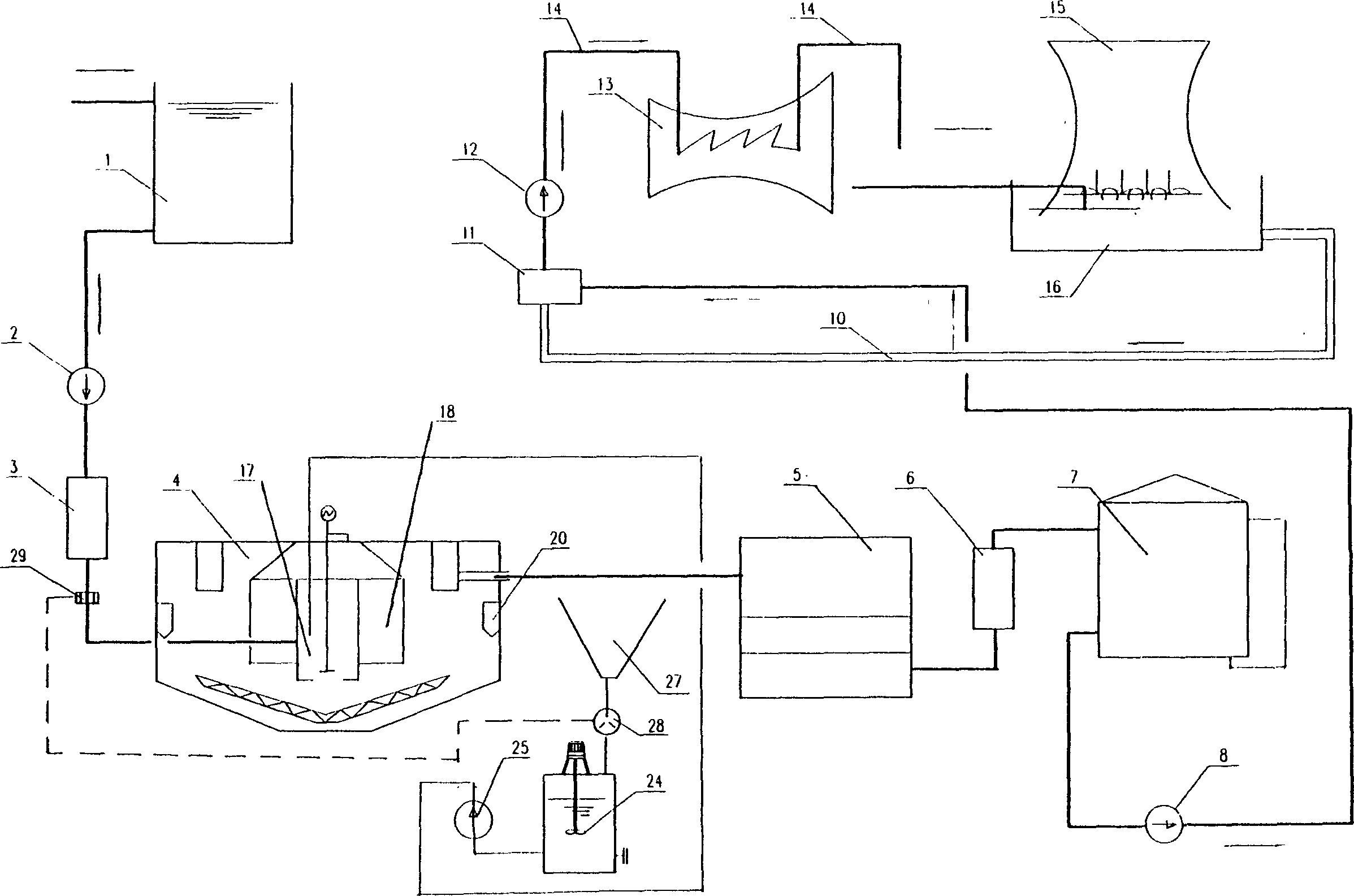

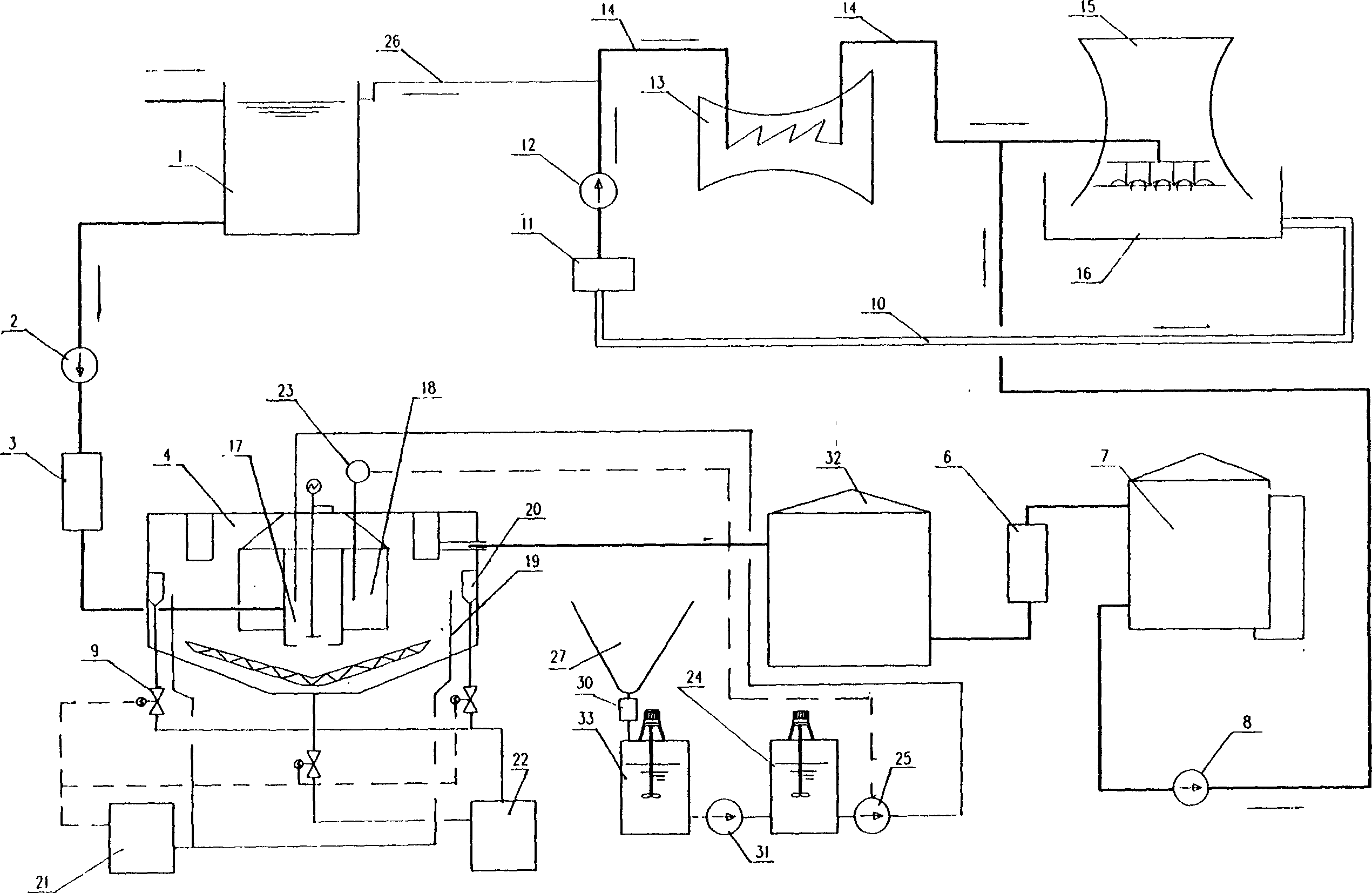

A technology of circulating cooling water and urban reclaimed water, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It is difficult to guarantee the effluent water quality of the clarification tank, and the backwashing effect of the square filter is not good, etc., to achieve stable and reliable effluent water quality, solve the large fluctuations in effluent water quality, and ensure low turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

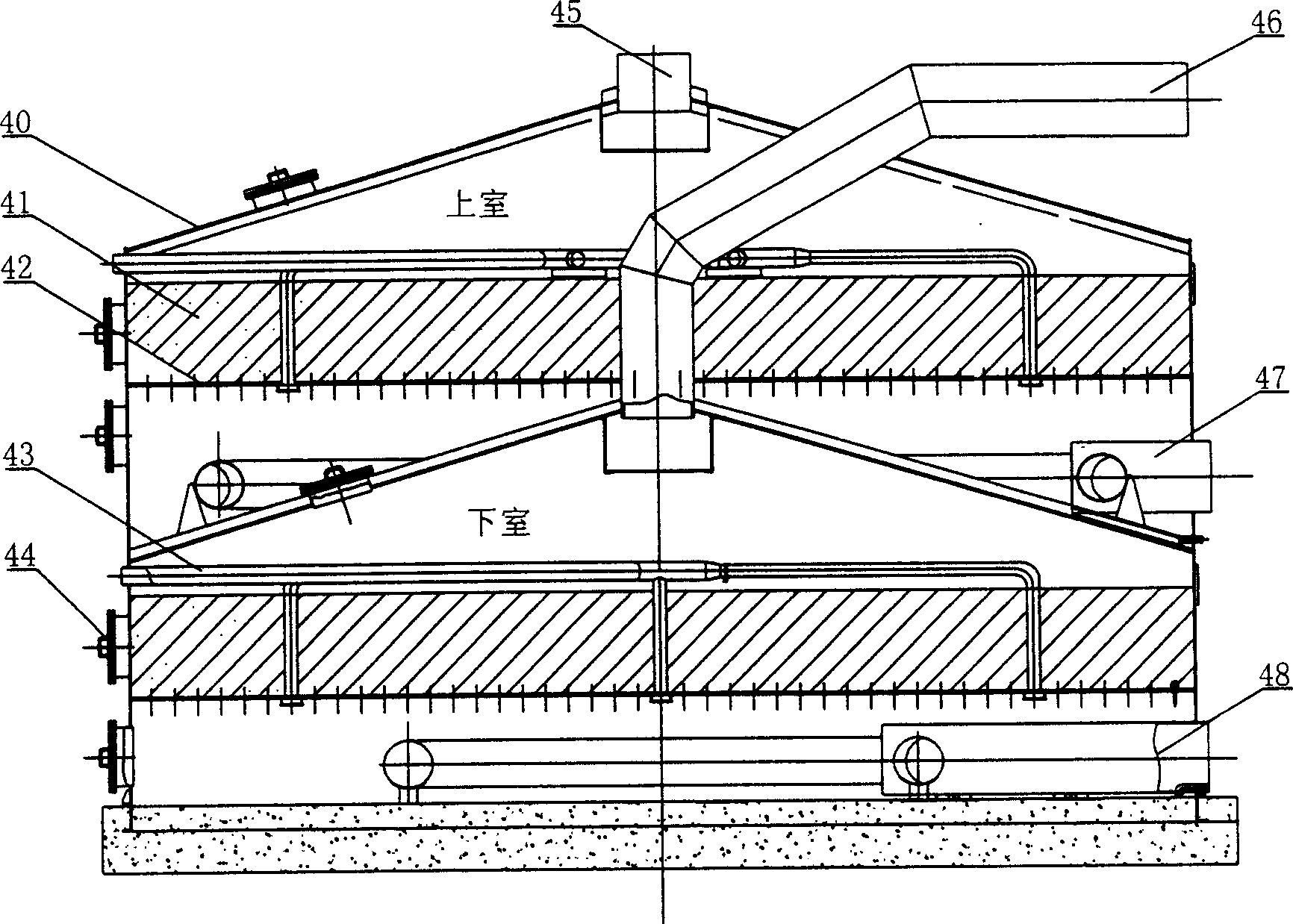

Method used

Image

Examples

Embodiment 1

[0040] The installed capacity of the power plant is designed to be 2×600MW condensing units, and urban reclaimed water is used as circulating water supplementary water. The indicators of water quality and replenishment volume are as follows:

[0041] Temporary hardness: 8mmol / L

[0042] SS (suspended solids) 20mg / L

[0043] BOD 5 20mg / L

[0044] COD60mg / L

[0045] NH 3 -N 8mg / L

[0046] Total amount of circulating water: Q=130000m 3 / h

[0047] The concentration ratio is calculated by 5 times:

[0048] Sewage volume: 340m 3 / h

[0049] Wind loss: 130m 3 / h

[0050] Evaporation loss: 1886m 3 / h

[0051] Total supplementary water volume: 2356m 3 / h

[0052] Using the urban reclaimed water adopted in the present invention as an advanced treatment method for industrial circulating cooling water, the reclaimed water advanced treatment system is designed to normally handle 2500m of water 3 / h, the maximum water treatment capacity is 3000m 3 / h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com