Preparation method of nanometer titanium dioxide composite nanometer silver sol

A nano-titanium dioxide, nano-silver sol technology, applied in chemical instruments and methods, botanical equipment and methods, separation methods, etc., can solve the problems of narrowing the scope of application, inability to use, etc., to expand the scope of application, easy operation, and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

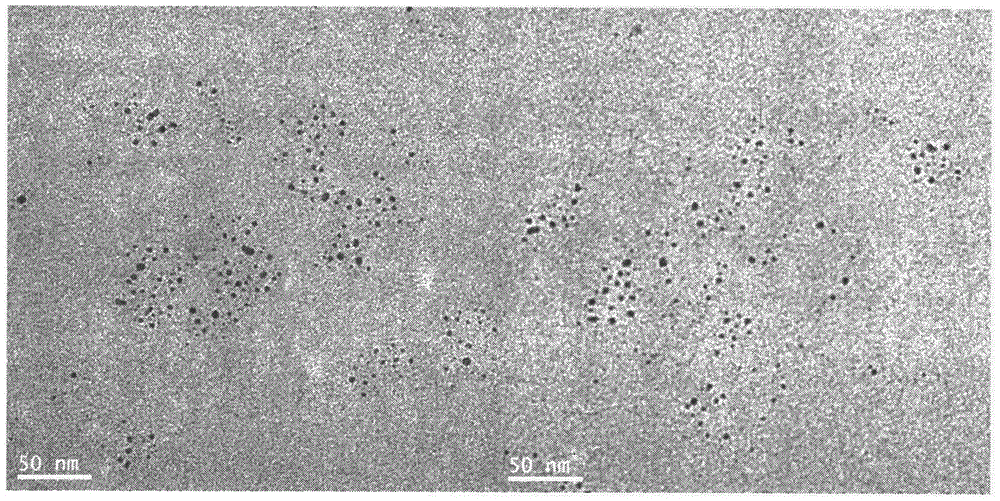

Image

Examples

Embodiment 1

[0029] Embodiment 1 The preparation method of this nano-titanium dioxide composite nano-silver sol comprises the following steps:

[0030] (1) Add 15 g of titanyl sulfate to 1000 g of deionized water to prepare a solution. After stirring for 30 minutes, adjust the pH value to 7 with 25% ammonia water, and continue stirring for 30 minutes to prepare a titanium hydroxide solution.

[0031] (2) Add 15 g of stabilizer organic acid citric acid to the titanium hydroxide solution, stir thoroughly for 30 minutes, then add 15 g of oxidant hydrogen peroxide, continue to stir fully and let the reaction solution stand for more than 10 hours.

[0032] (3) The reaction solution was placed in a reaction kettle with a reflux device under the condition of 100° C. and a stirring speed of 250 rpm, and reacted for 4 hours to obtain a transparent nano-titanium dioxide sol.

[0033] (4) 4.5g of polyvinylpyrrolidone and 100g of glycerol were dissolved in the nano-titanium dioxide sol to form a reduc...

Embodiment 2

[0043] Embodiment 2 The preparation method of this nano-titanium dioxide composite nano-silver sol comprises the following steps:

[0044] (1) Add 5 g of titanyl sulfate to 1000 g of deionized water to prepare a solution, stir thoroughly for 30 minutes, adjust the pH value to 8 with 10% ammonia water, and continue stirring for 1 hour to prepare a titanium hydroxide solution.

[0045] (2) Add 0.05 g of stabilizer organic acid citric acid to the titanium hydroxide solution, stir thoroughly for 30 minutes, then add 5 g of oxidant hydrogen peroxide, continue to stir fully, and let the reaction solution stand for 12 hours.

[0046] (3) The reaction solution was placed in a reaction kettle with a reflux device under the condition of 90° C. and a stirring speed of 50 rpm, and reacted for 2 hours to obtain a transparent nano-titanium dioxide sol.

[0047] (4) 15g of sodium dodecylbenzenesulfonate and 150g of propylene glycol were dissolved in the nano-titanium dioxide sol to form a re...

Embodiment 3

[0057] Example 3 The preparation method of the nano-titanium dioxide composite nano-silver sol comprises the following steps:

[0058] (1) Add 4 kg of titanyl sulfate to 400 kg of deionized water to prepare a solution. After stirring for 30 minutes, adjust the pH value to 9 with 15% ammonia water, and continue stirring for 30 minutes to obtain a titanium hydroxide solution.

[0059] (2) Add 4 kg of stabilizer organic acid citric acid to the titanium hydroxide solution, stir thoroughly for 30 minutes, then add 40 kg of oxidizing agent hydrogen peroxide, continue to stir fully and let the reaction solution stand for 12 hours.

[0060] (3) The reaction solution was placed in a reaction kettle with a reflux device under the condition of 120° C. and a stirring speed of 500 rpm, and reacted for 6 hours to obtain a transparent nano-titanium dioxide sol.

[0061] (4) Dissolving 50kg of β-cyclodextrin and 400kg of ethylene glycol in the nano titanium dioxide sol to form a reducing solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com