Butyl rubber based pressure-sensitive protective tape and preparation method thereof

A technology of protective tape and butyl rubber, which is applied in the direction of pressure-sensitive film/sheet, adhesive, film/sheet adhesive, etc. It can solve the problems of poor vulcanization performance and self-adhesive performance, and achieve good application prospects. Simple preparation method, excellent mechanical and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

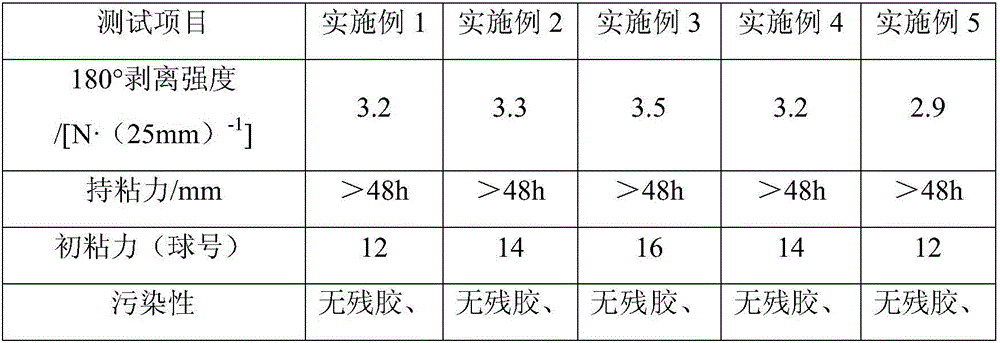

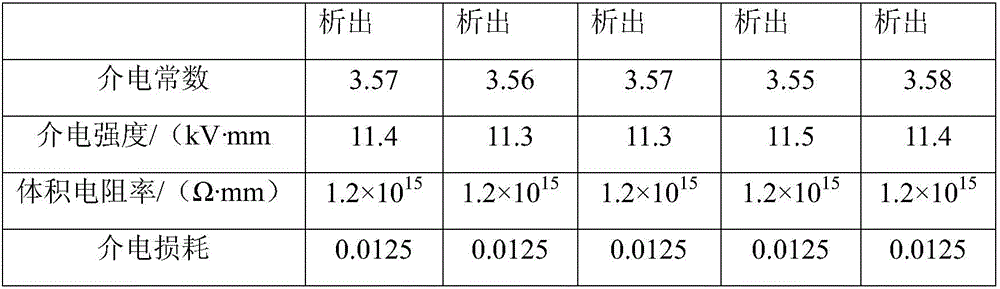

Examples

Embodiment 1

[0022] Formula: 5 parts of butyl rubber, 35 parts of polyisobutylene, 35 parts of alkylphenolic resin, 7 parts of polyethylene wax, 10 parts of liquid nitrile rubber, 8 parts of kaolin, 100 parts in total.

[0023] (1) Cut butyl rubber and polyisobutylene into small pieces and put them into the open plastic mixer according to the proportion, and pass them several times; then put them into the kneader, and add alkyl phenolic resin, polyethylene wax, Liquid nitrile rubber and kaolin are uniformly kneaded in a vacuum kneader, and discharged to obtain a pressure-sensitive adhesive;

[0024] (2) Dissolve every 100 parts of the prepared pressure-sensitive adhesive with 200 parts of solvent (butanone and ethyl acetate with a mass ratio of 45:55) to obtain a pressure-sensitive adhesive solution; apply the pressure-sensitive adhesive solution evenly by coating method Cover the surface of the substrate layer to form a pressure-sensitive adhesive layer, dry, wind up, and cut to obtain a ...

Embodiment 2

[0027] Formula: 15 parts of butyl rubber, 35 parts of polyisobutylene, 25 parts of alkylphenolic resin, 7 parts of polyethylene wax, 10 parts of liquid nitrile rubber, 8 parts of kaolin, 100 parts in total.

[0028] (1) Cut butyl rubber and polyisobutylene into small pieces and put them into the open plastic mixer according to the proportion, and pass them several times; then put them into the kneader, and add alkyl phenolic resin, polyethylene wax, Liquid nitrile rubber and kaolin are uniformly kneaded in a vacuum kneader, and discharged to obtain a pressure-sensitive adhesive;

[0029] (2) Dissolve every 100 parts of the prepared pressure-sensitive adhesive with 200 parts of solvent (butanone and ethyl acetate with a mass ratio of 45:55) to obtain a pressure-sensitive adhesive solution; apply the pressure-sensitive adhesive solution evenly by coating method Cover the surface of the substrate layer to form a pressure-sensitive adhesive layer, dry, wind up, and cut to obtain a...

Embodiment 3

[0032] Formula: 20 parts of butyl rubber, 30 parts of polyisobutylene, 25 parts of alkylphenolic resin, 7 parts of polyethylene wax, 10 parts of liquid nitrile rubber, 8 parts of kaolin, 100 parts in total.

[0033] (1) Cut butyl rubber and polyisobutylene into small pieces and put them into the open plastic mixer according to the proportion, and pass them several times; then put them into the kneader, and add alkyl phenolic resin, polyethylene wax, Liquid nitrile rubber and kaolin are uniformly kneaded in a vacuum kneader, and discharged to obtain a pressure-sensitive adhesive;

[0034] (2) Dissolve every 100 parts of the prepared pressure-sensitive adhesive with 250 parts of solvent (butanone and n-butyl acetate with a mass ratio of 33:67) to obtain a pressure-sensitive adhesive solution; apply the pressure-sensitive adhesive solution evenly Coating on the surface of the substrate layer to form a pressure-sensitive adhesive layer, drying, winding, and slitting to obtain a bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com