Anthracene-series sensitizer and application of same in UV-LED light-curing system

A sensitizer, CH3- technology, used in the preparation of organic compounds, photosensitive materials for optomechanical equipment, optics, etc., can solve the problem of unsmooth curing and poor curing effects, which limit the development of UV-LED light curing technology and promotion issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]

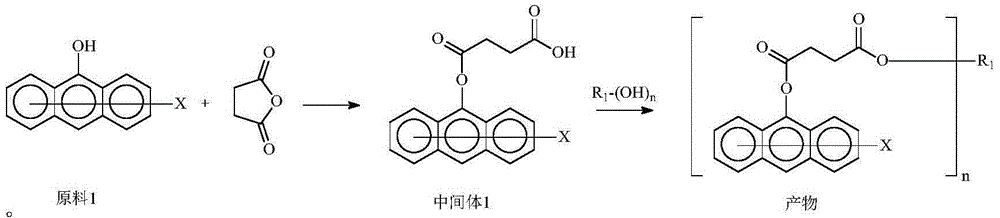

[0028] (1) Preparation of Intermediate 1a

[0029] Add 194g of raw materials 9-hydroxyanthracene, 100g of succinic anhydride, and 200mL of dichloromethane into a 1000mL four-neck flask, heat to reflux at 40°C, track the liquid phase until the reaction no longer changes, close the reaction, and pour the reaction solution into water. After stirring, the dichloromethane layer was separated, washed with water, and the dichloromethane layer was rotary evaporated to obtain 268g of intermediate 1a.

[0030] The structure of intermediate 1a has been 1 H-NMR was confirmed, and the characterization results are as follows.

[0031] 1 H-NMR (CDCl 3 ,500MHz): 2.5065-2.6432(4H,t), 7.3149-8.2388(9H,m), 10.9921-11.9828(1H,s).

[0032] (2) Preparation of compound 1

[0033] Add 147g of intermediate 1a, 100mL of methanol, and 3g of 70% concentrated sulfuric acid into a 500mL four-necked flask, connect the distillation device and water separator, add 5mL of toluene into the wate...

Embodiment 2

[0037]

[0038] Add 147g of intermediate 1a, 100mL of ethylene glycol, 8g of 70% concentrated sulfuric acid, and 100mL of toluene into a 500mL four-neck flask, connect the distillation device and water separator, add 5mL of toluene into the water separator, and heat to reflux at 110°C while The water produced by the reaction was evaporated during the reaction, and the liquid phase followed the reaction until there was no change, then distilled off excess toluene, washed to remove ethylene glycol, and recrystallized petroleum ether to obtain 146g of white viscous material with a yield of 95%. 99%, namely compound 2.

[0039] product structure 1 H-NMR was confirmed, and the characterization results are as follows.

[0040] 1 H-NMR (CDCl 3 ,500MHz):2.4692-2.6144(8H,t),4.3329-4.4128(4H,t),7.3951-8.2196(18H,m).

Embodiment 3-10

[0042] With reference to the method of embodiment 1 and 2, synthetic compound 3-8, its structure and corresponding 1 H-NMR data are listed in Table 1.

[0043] Table 1

[0044]

[0045]

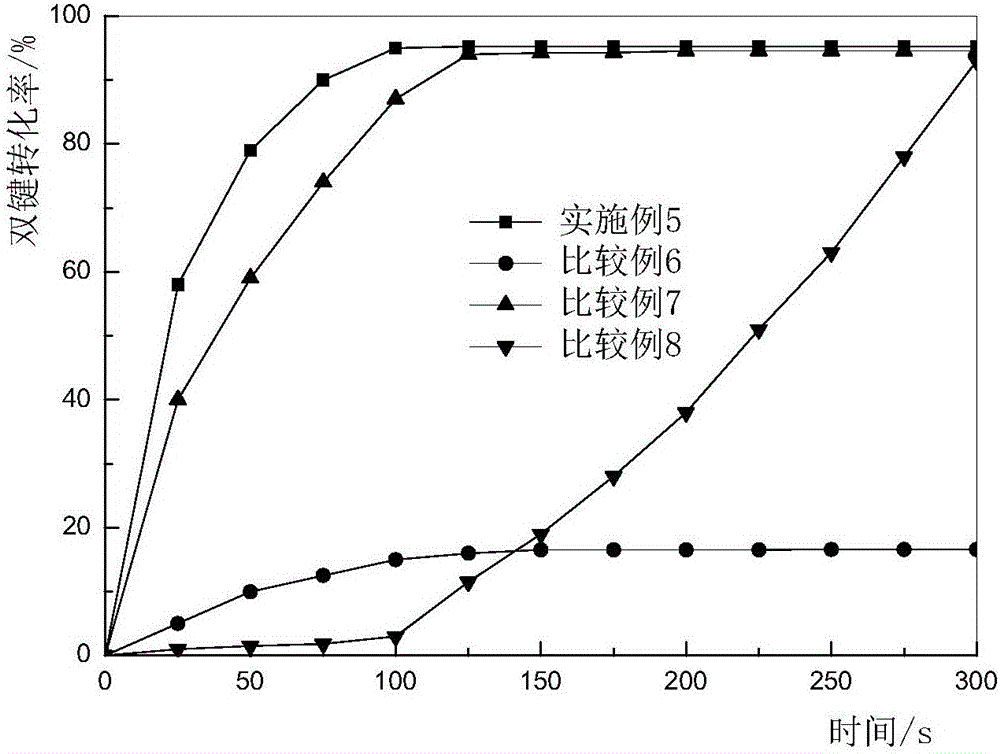

[0046] performance evaluation

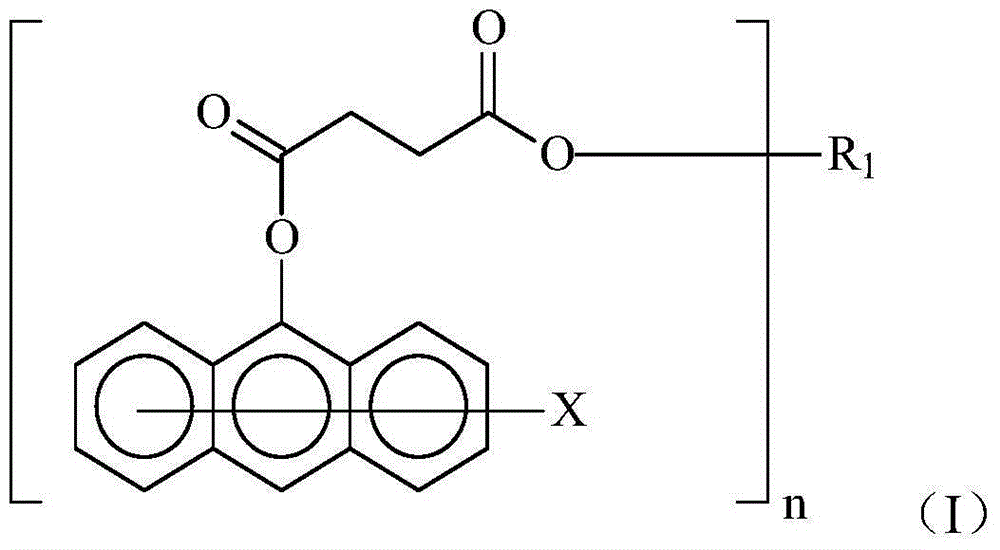

[0047] By preparing an exemplary photocurable composition (ie, a photosensitive resin composition), the application performance of the sensitizer represented by formula (I) of the present invention is evaluated.

[0048] 1. Preparation of photosensitive resin composition

[0049] The photosensitive resin composition was prepared with reference to the following proportions and the specific formula shown in Table 2.

[0050]

[0051] Table 2

[0052]

[0053] 2. Film-forming performance test

[0054] (1) Film forming performance test under high pressure mercury lamp

[0055] Stir the above composition under a yellow light, take the material and roll-coat it on a PET template to form a film, dry at 90°C for 5 minutes to remove the solvent, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com