Recycled asphalt concrete and preparation process thereof

A technology for reclaiming asphalt and concrete, which is applied in the field of asphalt concrete, which can solve the problems of easy cracks and poor bonding at the splicing joints, and achieve the effects of good compound synergy, improved bonding strength, and good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

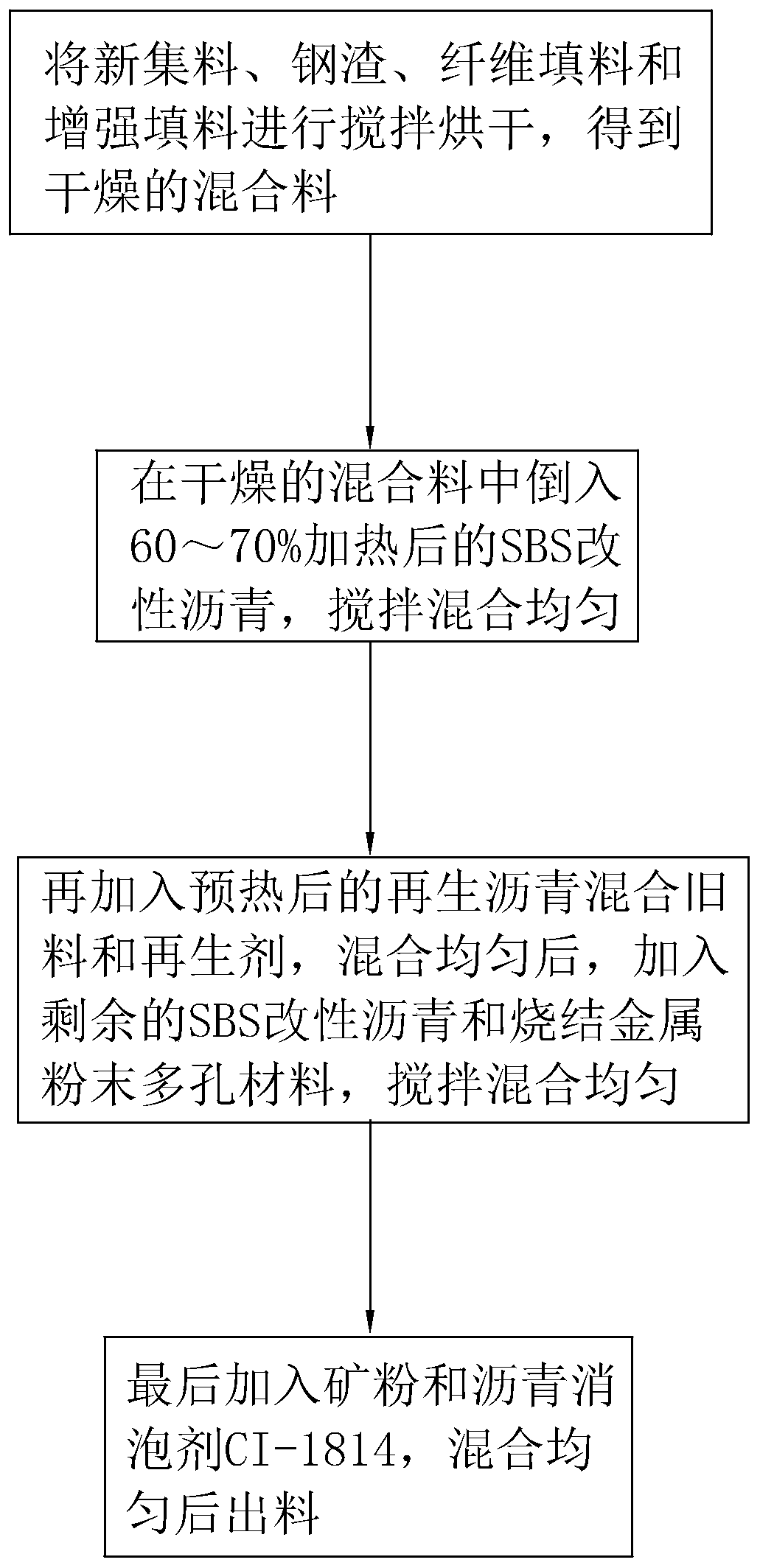

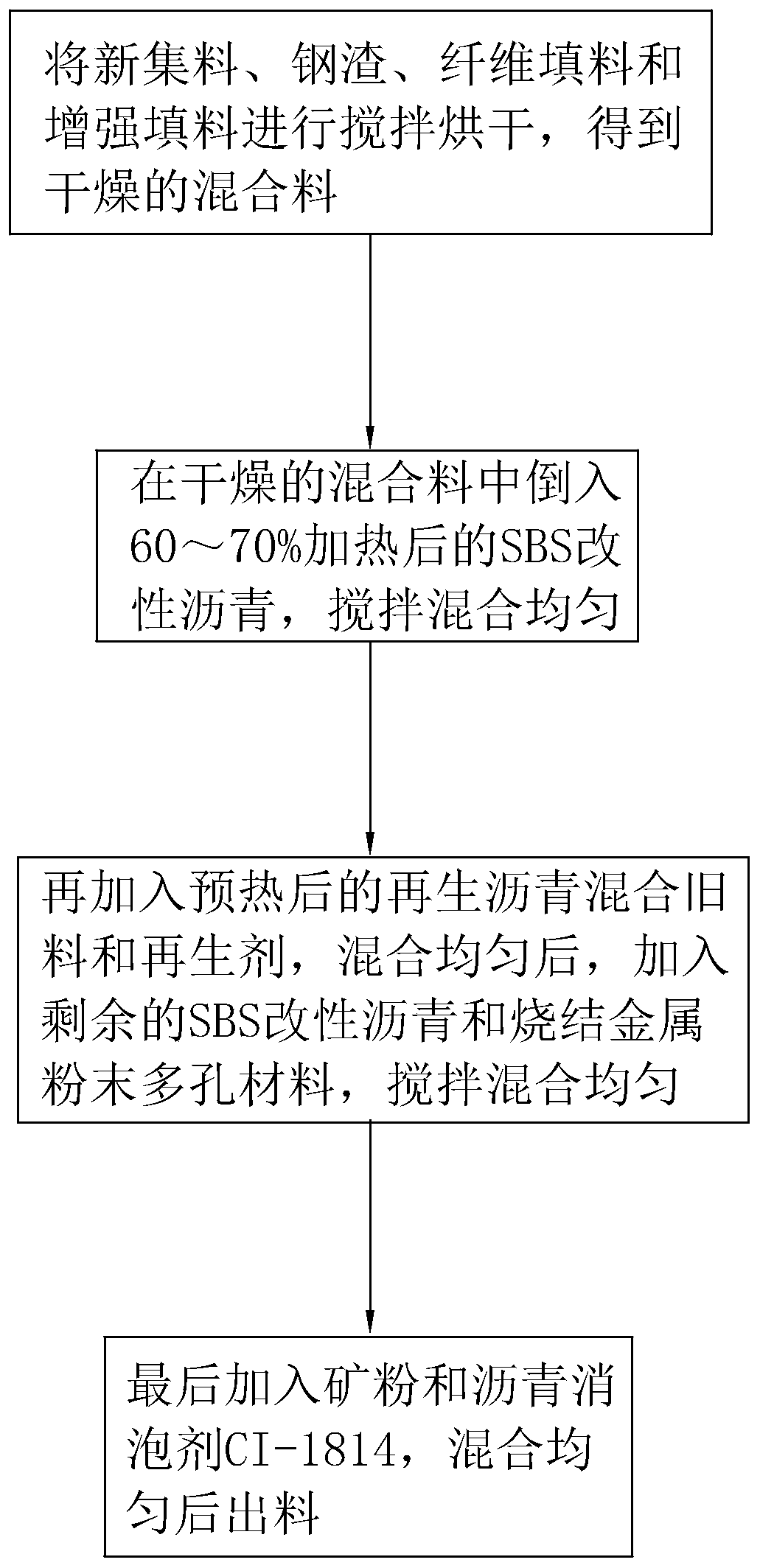

[0046] Embodiment 1: A kind of recycled asphalt concrete, each component and its corresponding parts by weight are shown in Table 1, and prepared by the following steps:

[0047] Step 1: Stir and dry the new aggregate, steel slag, lignin fiber and glass microspheres in the drying barrel with the corresponding weight parts, the temperature is controlled at 100°C, the time is 25min, and the stirring speed is 1200rpm to obtain dried Mixture;

[0048] Step 2, put the dry mixture into the mixing tank, heat 60% by weight of SBS modified asphalt to 170°C, add it into the mixing tank evenly within 30s, and stir at a stirring speed of 900rpm;

[0049] Step 3: Preheat the regenerated asphalt mixed old material to 80°C and add it together with the regeneration agent into the above mixing tank for stirring. The temperature in the mixing tank is maintained at 170°C, the stirring speed is 900rpm, and the time is 30min. Then add the remaining 40% by weight of SBS modified asphalt and sinter...

Embodiment 2-8

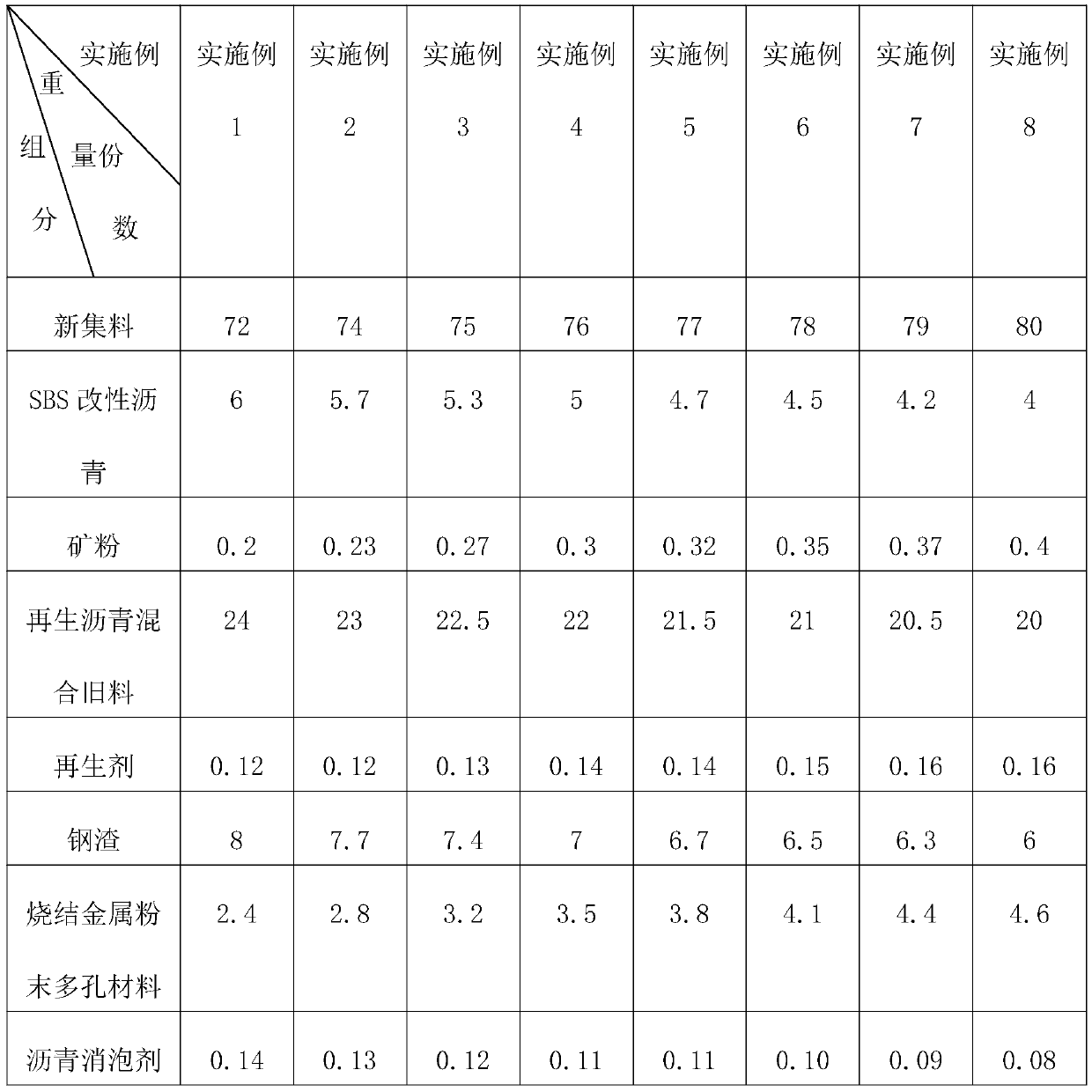

[0052] Example 2-8: A recycled asphalt concrete, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0053] Each component and parts by weight thereof in table 1 embodiment 1-8

[0054]

[0055]

Embodiment 9

[0056] Example 9: A recycled asphalt concrete, the difference from Example 1 is that the new aggregate is mainly composed of limestone with a particle size range of 0-3mm, 3-5mm, 5-13mm, 13-20mm, and 20-25mm The ratio of parts by weight is 1.5:2.3:7.4:1:3.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com