Concrete additive capable of solidifying chlorions efficiently for long time as well as application

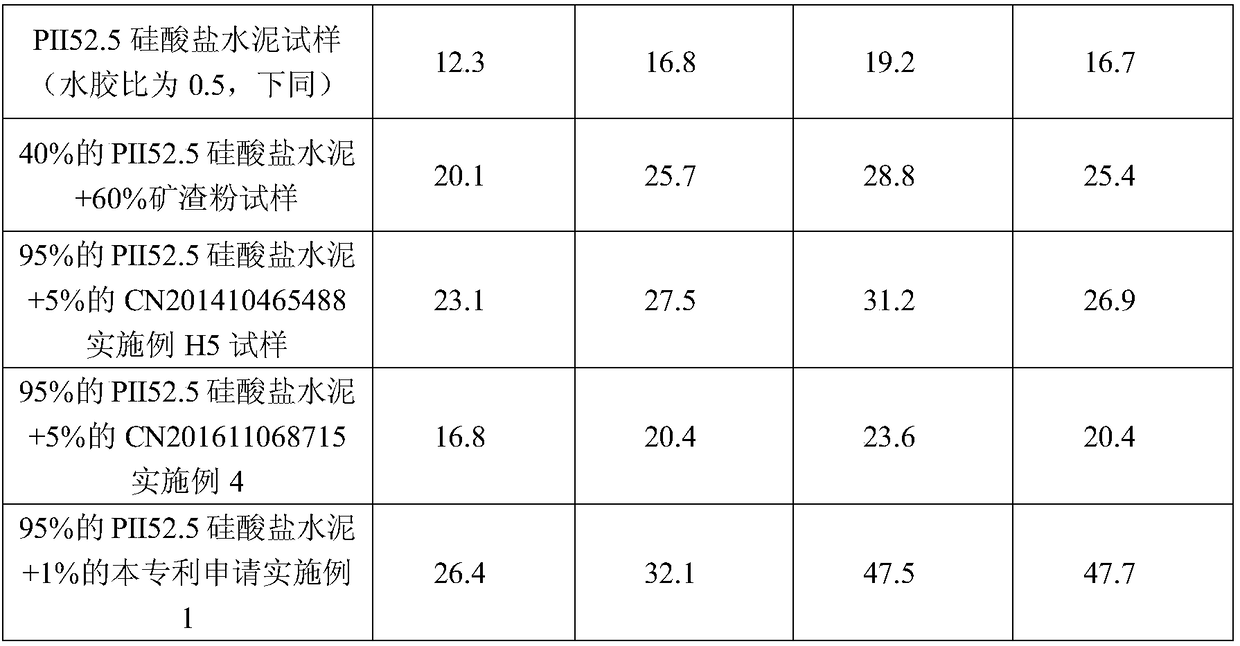

A technology of concrete admixture and chloride ion, which is applied in the field of building materials, can solve the problems of chloride ion transmission performance, reduced concrete fluidity, high dosage, etc., to achieve enhanced physical adsorption capacity and stability, high curing capacity, The effect of slowing down the transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A concrete admixture for long-term efficient curing of chloride ions, which comprises the following steps:

[0045] Silica-alumina components, basic components, reaction control components, calcareous components and surface modification components

[0046] Si-alumina component: China Kaolin Co., Ltd., calcined superfine kaolin, 46.75%;

[0047] Alkaline component: Nanjing Chemical Reagent Co., Ltd., sodium hydroxide (industrial grade), 15%;

[0048] Sodium silicate solution (technical grade), SiO 2 / Na 2 O is 2.0 (solid content is 40%), 35%;

[0049] Reaction control components: Nanjing Chemical Reagent Co., Ltd., sodium tetraborate (chemically pure), 0.5%;

[0050] Zinc sulfate (chemically pure), 0.5%

[0051] Calcium component: Nanjing Chemical Reagent Co., Ltd., calcium hydroxide (chemically pure), 2%;

[0052] Surface modification components: Shanghai Aladdin Biochemical Technology Co., Ltd., polyaluminum chloride (chemically pure), 0.5%;

[0053] Preparati...

Embodiment 2

[0063] A concrete admixture for long-term efficient curing of chloride ions, which comprises the following steps:

[0064] Silica-alumina components, basic components, reaction control components, calcareous components and surface modification components

[0065] Si-alumina component: Weifang Huawei Bentonite Group Co., Ltd., calcined bentonite, 20%;

[0066] Alkaline component: Nanjing Wanqing Huabo Instrument Co., Ltd., sodium hydroxide (industrial grade), 15%;

[0067] Potassium Silicate Solution (Technical Grade), SiO 2 / K 2 O is 1.5 (solid content is 40%), 35%;

[0068] Reaction control components: Nanjing Wanqing Huabo Instrument Co., Ltd., barium chloride (chemically pure), 7%;

[0069] Zinc sulfate (chemically pure), 3%

[0070] Calcium component: Nanjing Suluotian Trading Co., Ltd., slag powder, 10%;

[0071] Surface modification components: Nanjing Wanqing Huabo Instrument Co., Ltd., polyphosphorus ferric sulfate (chemically pure), 10%;

[0072]Preparation m...

Embodiment 3

[0080] A concrete admixture for long-term efficient curing of chloride ions, which comprises the following steps:

[0081] Silica-alumina components, basic components, reaction control components, calcareous components and surface modification components

[0082] Si-alumina component: China Kaolin Co., Ltd., calcined superfine kaolin, 20%;

[0083] Weifang Huawei Bentonite Group Co., Ltd., calcined bentonite, 15%;

[0084] Alkaline component: Nanjing Wanqing Huabo Instrument Co., Ltd., sodium hydroxide (industrial grade), 10%;

[0085] Sodium silicate solution (technical grade), SiO 2 / Na 2 O is 1.8 (solid content is 40%), 30%;

[0086] Reaction control components: Nanjing Wanqing Huabo Instrument Co., Ltd., sodium tetraborate (chemically pure), 6%;

[0087] Zinc sulfate (chemically pure), 3%;

[0088] Calcium component: Nanjing Suluotian Trading Co., Ltd., slag powder, 8%;

[0089] Surface modification components: Nanjing Wanqing Huabo Instrument Co., Ltd., polyphosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com