Integral wind-power blade ultraviolet light/electron beam in situ curing fiber laying forming device and integral wind-power blade ultraviolet light/electron beam in situ curing fiber laying forming method

An electron beam curing, wind power blade technology, applied in the field of wind power blade manufacturing, can solve the problems of high labor intensity, low degree of automation, low degree of automation, etc., to improve manufacturing quality and service life, efficient automated manufacturing, and improve manufacturing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

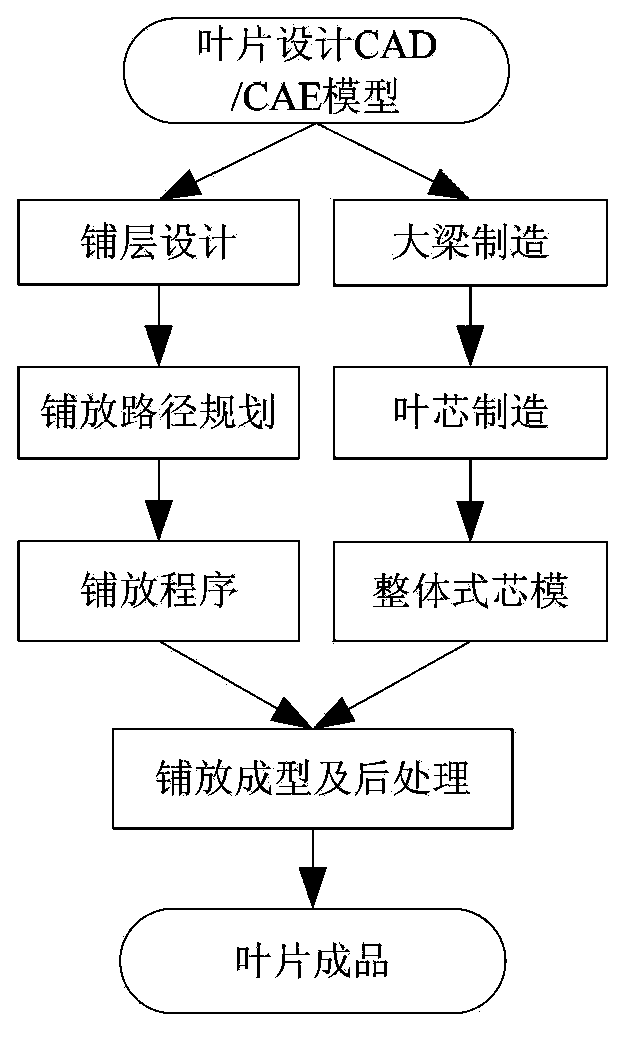

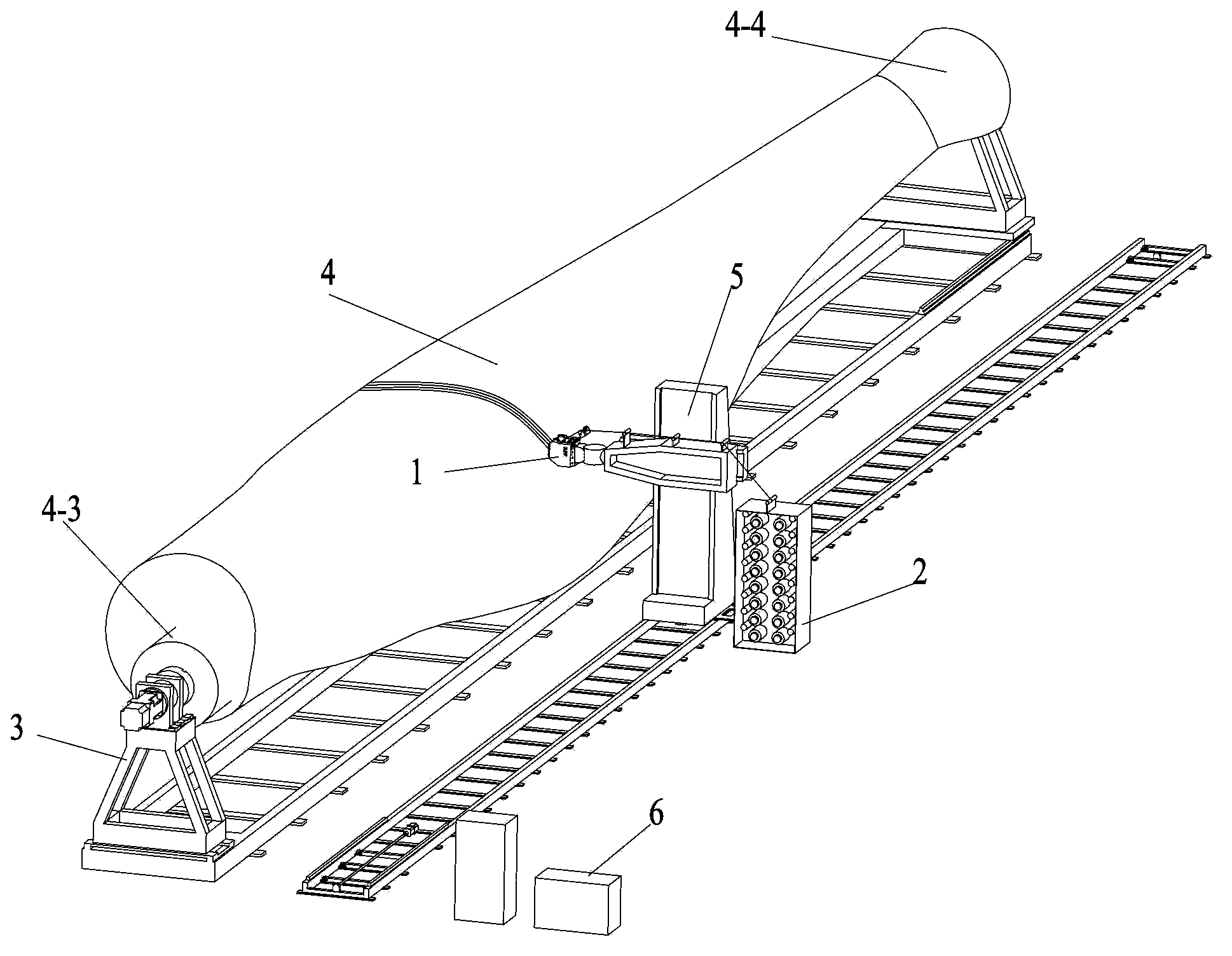

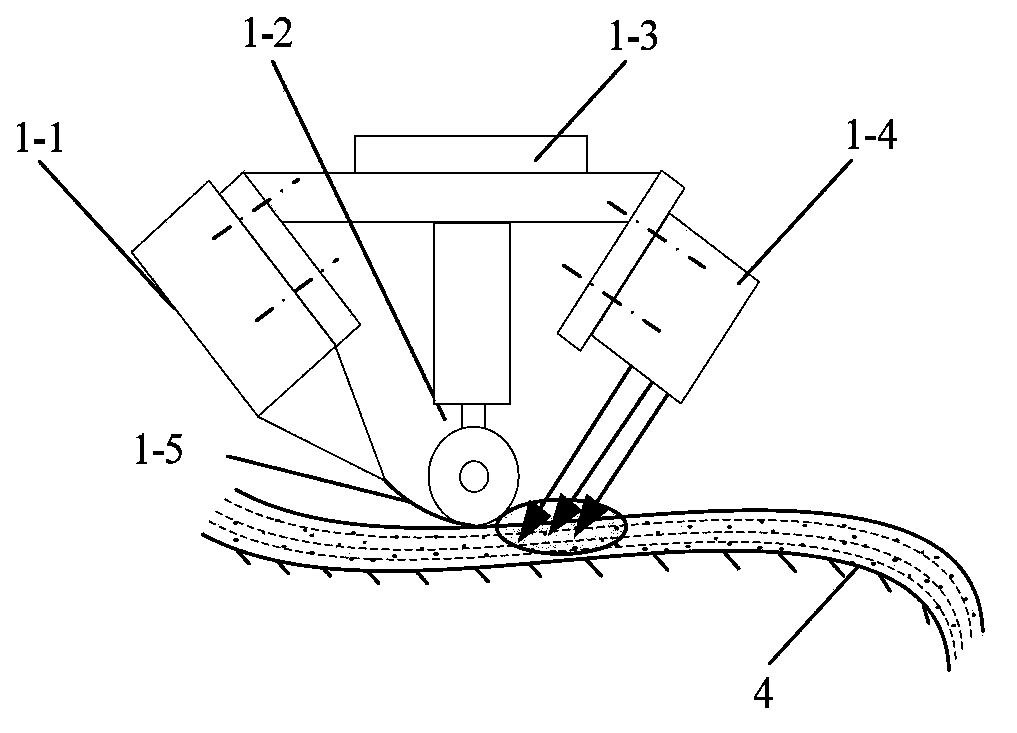

[0041] The present invention adopts an ultraviolet light / electron beam in-situ curing fiber laying manufacturing method and device. The method uses an ultraviolet light / electron beam in-situ curing process to complete the forming and curing process of large-scale wind power blades at one time, and the overall molding improves the curing efficiency and blade At the same time, combined with the large-scale wind power blade fiber placement manufacturing system, including: UV / electron beam in-situ curing fiber placement head, prepreg belt conveying system, integral mandrel support device, and large-scale wind power blade integral mandrel , horizontal or vertical multi-degree-of-freedom machine tool system, laying control system and multi-axis linkage control system to realize the automatic manufacturing of integral large-scale wind power blades. The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com