Ceramic part 3D (three dimensional) printing method based on adhesives of dual curing systems

A ceramic parts, dual-curing technology, applied in the field of additive manufacturing, can solve the problems of high surface tension, low forming efficiency, reducing forming accuracy, etc., and achieve the effect of improving dimensional accuracy, small shrinkage deformation, and small surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

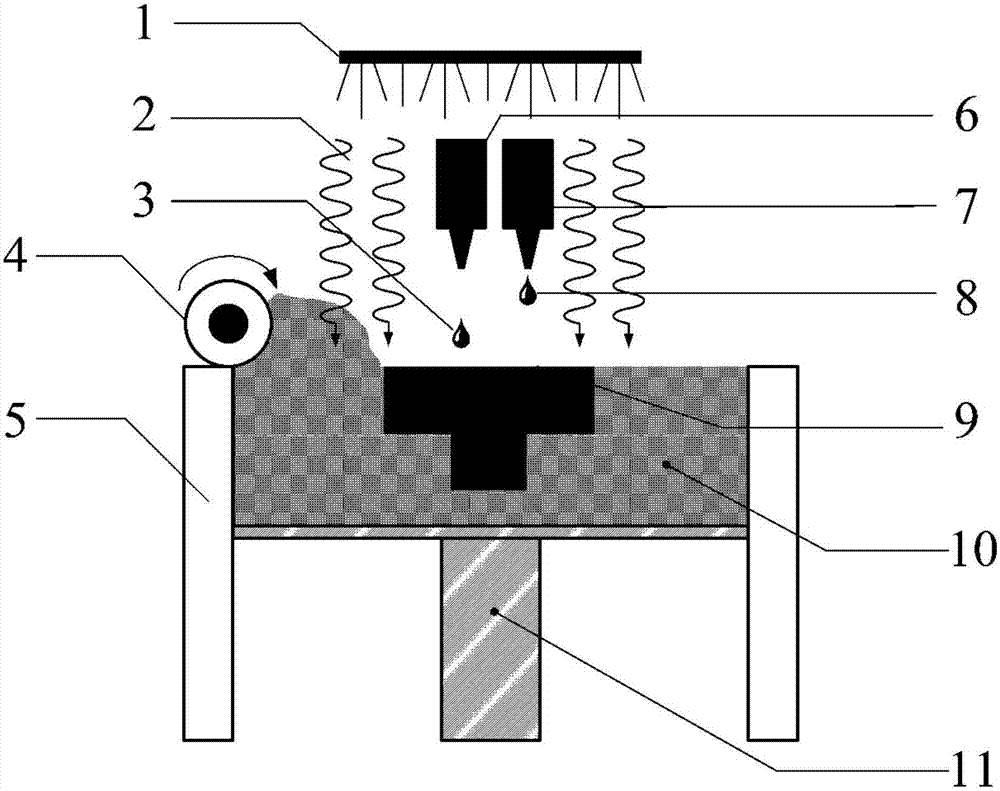

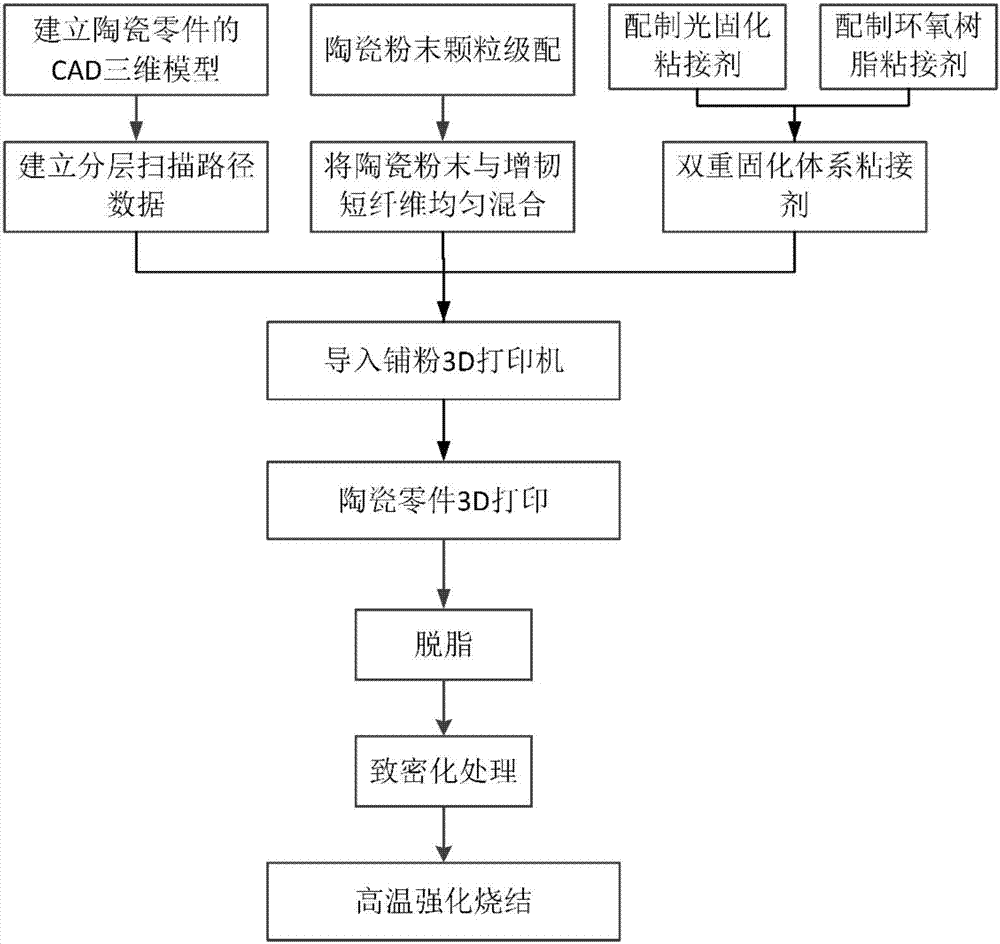

Method used

Image

Examples

Embodiment 1

[0037] A kind of Al based photocurable adhesive provided by the invention 2 O 3 The 3D printing method of ceramic parts, the details are as follows:

[0038] 1) 85% mass fraction of photosensitive resin is used as the adhesive matrix material, 10% mass fraction of ethanol modifier is added to modify the adhesive, and 3% mass fraction of photoinitiator is added to improve the optical properties of the adhesive. Curing rate, add 2% mass fraction of colorant to color the adhesive, and prepare the photosensitive resin-based adhesive of the first heavy curing system;

[0039] 2) Using 90% mass fraction of epoxy resin as the adhesive matrix material, adding 10% mass fraction of ethylene glycol modifier to modify the adhesive, as the first component of two-component curing, using poly Thiol (low temperature fast curing agent for epoxy resin), as the second component of two-component curing, constitutes the second heavy curing system;

[0040] 3) after mixing the photosensitive res...

Embodiment 2

[0048] The invention provides a 3D printing method for CaO-MgO composite ceramic parts based on a light-curing adhesive, the specific contents are as follows:

[0049] 1) 85% mass fraction of photosensitive resin is used as the adhesive matrix material, 10% mass fraction of ethanol modifier is added to modify the adhesive, and 3% mass fraction of photoinitiator is added to improve the optical properties of the adhesive. Curing rate, add 2% mass fraction of colorant to color the adhesive, and prepare the photosensitive resin-based adhesive of the first heavy curing system;

[0050] 2) Using 90% mass fraction of epoxy resin as the adhesive matrix material, adding 10% mass fraction of ethylene glycol modifier to modify the adhesive, as the first component of two-component curing, using poly Thiol (low temperature fast curing agent for epoxy resin), as the second component of two-component curing, constitutes the second heavy curing system;

[0051] 3) after mixing the photosensi...

Embodiment 3

[0059] The present invention provides a 3D printing method for SiC composite ceramic parts based on a light-curing adhesive, the details of which are as follows:

[0060] 1) 85% mass fraction of photosensitive resin is used as the adhesive matrix material, 10% mass fraction of ethanol modifier is added to modify the adhesive, and 3% mass fraction of photoinitiator is added to improve the optical properties of the adhesive. Curing rate, add 2% mass fraction of colorant to color the adhesive, and prepare the photosensitive resin-based adhesive of the first heavy curing system;

[0061] 2) Using 90% mass fraction of epoxy resin as the adhesive matrix material, adding 10% mass fraction of ethylene glycol modifier to modify the adhesive, as the first component of two-component curing, using poly Thiol (low temperature fast curing agent for epoxy resin), as the second component of two-component curing, constitutes the second heavy curing system;

[0062] 3) after mixing the photose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com