Method for preparing polyolefin-based complex fiber through modified nano-particles

A nanoparticle and composite fiber technology, applied in the direction of single-component polyolefin rayon filament, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of improving the dispersibility and compatibility of nanoparticles, the effect is not ideal, and it is difficult to control. , to achieve the effect of overcoming steric hindrance effect, improving mechanical properties, and strong design ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

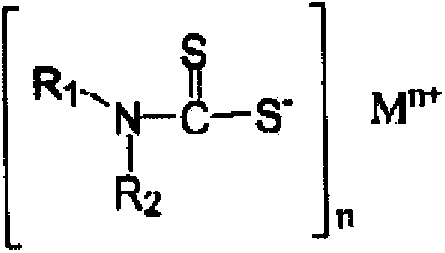

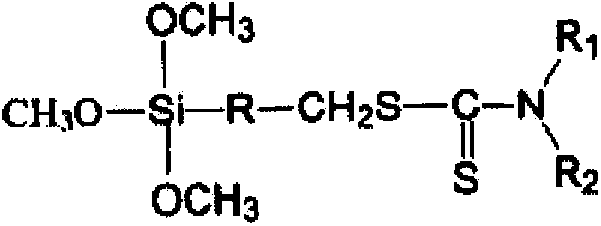

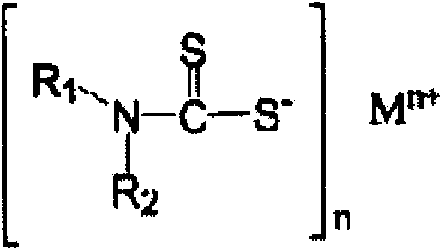

[0031] 4-(Chloromethyl)phenyltrimethoxysilane and sodium diethyldithiocarbamate were dissolved in tetrahydrofuran at a ratio of 1:1 to obtain mixed solution a and mixed solution b respectively. Then slowly add b to a, stir at room temperature for 5 hours, filter the precipitate, and then remove the solvent by vacuum distillation at 170°C to obtain a free radical that can react with the hydroxyl group on the surface of nanoparticles and has an initiating monomer to carry out active free radicals The viscous liquid CNS (I) of polymerization function, standby;

[0032]Nano-SiC is placed in a mixture of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 3:1, refluxed at 95°C for 10 h, then centrifugally filtered, washed with deionized water, and dried in a drying oven for 15 h to obtain hydroxylated SiC. Nanoparticles, spare;

[0033] Dissolve a certain amount of CNS(I) in toluene, then add quantitatively the above-mentioned hydroxylated nanoparticles,...

Embodiment 2

[0037] γ-Chloropropyltrimethoxysilane and sodium dimethyldithiocarbamate were dissolved in tetrahydrofuran respectively according to the substance ratio of 1:1, and mixed solution a and mixed solution b were correspondingly obtained. Then slowly add b to a, stir at room temperature for 2 hours, filter the precipitate, and then remove the solvent by vacuum distillation at 160°C to obtain a free radical that can react with the hydroxyl group on the surface of nanoparticles and has an initiating monomer to carry out active free radicals Polymerized viscous liquid CNS (II), standby;

[0038] nano-SiO 2 Place in a mixture of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 3:1, reflux at 85°C for 5 hours, then centrifugally filter, wash with deionized water, and dry in a drying oven for 8 hours to obtain hydroxylated nanoparticles ,spare;

[0039] Using tetrahydrofuran as a solvent, dissolve a certain amount of CNS(II), then add a quantitative amount...

Embodiment 3

[0043] 4-(Chloromethyl)phenyltrimethoxysilane and potassium diethyldithiocarbamate are dissolved in tetrahydrofuran respectively according to the substance ratio of 1:1, and corresponding mixed solution a and mixed solution b are obtained . Then slowly add b to a, stir at room temperature for 3 hours, filter the precipitate, and then remove the solvent by vacuum distillation at 165°C to obtain a free radical that can react with the hydroxyl group on the surface of nanoparticles and has an initiating monomer to carry out active free radicals The viscous liquid CNS (III) of polymerization function, standby;

[0044] Nano-MgO was placed in a mixture of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 3:1, refluxed at 90°C for 8 hours, then centrifugally filtered, washed with deionized water, and dried in a drying oven for 12 hours to obtain hydroxylated Nanoparticles, spare;

[0045] Use toluene as a solvent to dissolve a certain amount of CNS(III)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com