Decorative sheet and decorative molded article

A decorative sheet, vacuum forming technology, applied in the direction of decorations, synthetic resin layered products, layered products, etc., can solve the problems of hindering cost reduction, productivity deterioration, etc., to achieve the suppression of unevenness on the surface, suppression of unevenness, excellent design sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] Next, examples of the present invention will be described.

[0128] This example is an example of producing a decorative sheet and using the decorative sheet to produce a decorative molded article.

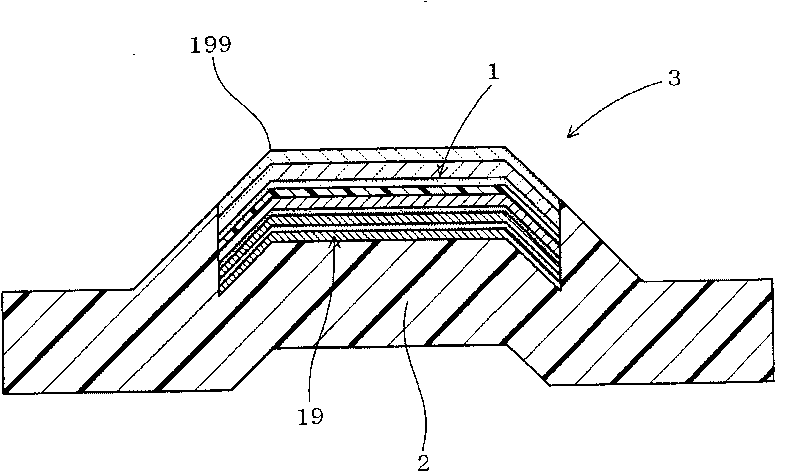

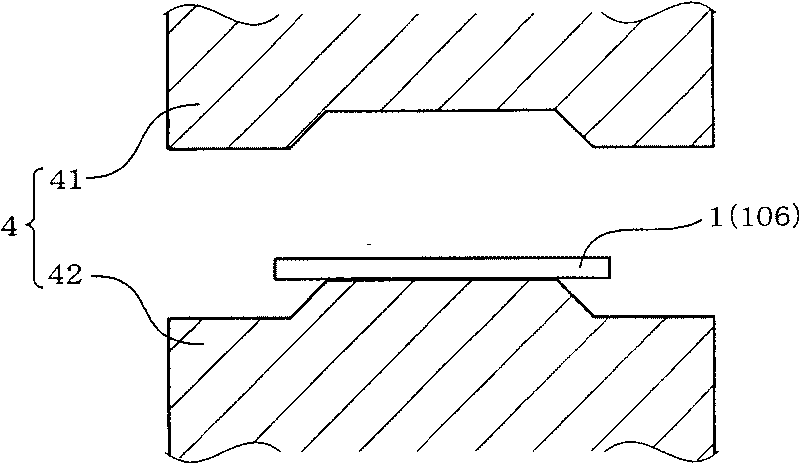

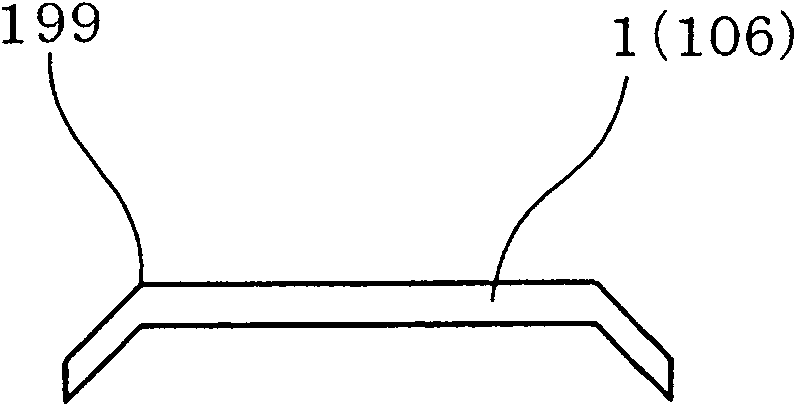

[0129] Such as Figure 1 ~ Figure 4 As shown, the decorative sheet 1 of this example forms the curved portion 19 by vacuum forming or thermocompression forming, and then, the base resin 2 is injection-molded on the back side 19 in the molding die 5, so that it is combined with the base resin 2. integrated and used.

[0130] Such as Figure 5 As shown, the decorative sheet 1 is formed by sequentially laminating the base-side adhesive layer 11, the porous decorative sheet 13, the filler layer 14, and the protective layer side from the back side 19 integrated by injection molding the base resin. The adhesive layer 15 and the transparent surface protection layer 16 are integrated. The substrate-side adhesive layer 11 is composed of a substrate-side adhesive layer 111 and a ...

Embodiment 2

[0215] 在本例子中,如 Figure 14 所示,与实施例1相同地,通过在装饰片1上形成弯曲部19,在装饰片1的背面侧19将基材树脂注塑成型,而制成装饰成型品3。

[0216] 本例子的装饰片如 Figure 15 所示,与实施例1相同地,从将基材树脂进行注塑并与其一体化的背面侧19,顺次层叠基材侧粘结层11、多孔质状的装饰片材13、填料层14、保护层侧粘结剂层15、及透明的表面保护层16,进行一体化而形成。基材侧粘结层11可以由基材接合层111和基材侧粘结剂层112构成。另外,表面保护层16可以由硬质涂层片材161和透明片材162构成。另外,装饰片13可以由刨切单板131、粘结层132和无纺布133构成。

[0217] 在本例子中,与实施例1相同地,将装饰片的结构、成型条件等进行变更而制作17种装饰成型品(试样E12~试样E22及试样C7~试样C 12)。在表5~表8中示出了各试样的装饰片的制作中使用的结构及成型条件。另外,表5~表8示出了装饰片(刨切单板)的材质、槽(导管)深度、保护层侧粘结剂层的厚度及其与槽(导管)深度之比(保护层侧粘结剂层的厚度 / 导管深度)。

[0218] 装饰片的槽深度是将在刨切单板剖面上的导管深度的最大值作为槽深度。在进行该测定时,使用“(株)キ一エンス”制造的“デジタルマイクロスコ一プVHX-900”进行测定。

[0219] exist Figure 16 (a)中,作为装饰片(刨切单板)的一个例子,示出古夷苏木(Bubinga)表面中的槽部(导管)的显微镜照片(倍率100倍)。 exist Figure 16 (b)中,示出在 Figure 16 (a)所示的线X上的槽部的深度。针对装饰片的表面整体进行槽部深度的测定,将该深度的最大值,即 Figure 16 (b)中的A-B间的高度的最大值,作为装饰片的槽深度(刨切单板的导管深度)。

[0220] 对于各试样(试样E12~试样E22及试样C7~试样C12),与实施例1相同地,通过目视观察,对图案面有无凹凸、有无浮起或剥落、有无气泡进行判定。此外,对装饰成型品的外表面的硬度及保护层侧粘结剂层的粘结强度进行测定。另外,将各试样在温度100℃的环境下载置400小时,进行耐热性的评价。耐热性的评价是通过目视观察400小时...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com