Method for leveling strip produced by secondary cold rolling unit

A secondary cold rolling and strip technology, applied in the field of strip rolling, can solve problems such as unstable surface quality and poor control of product shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

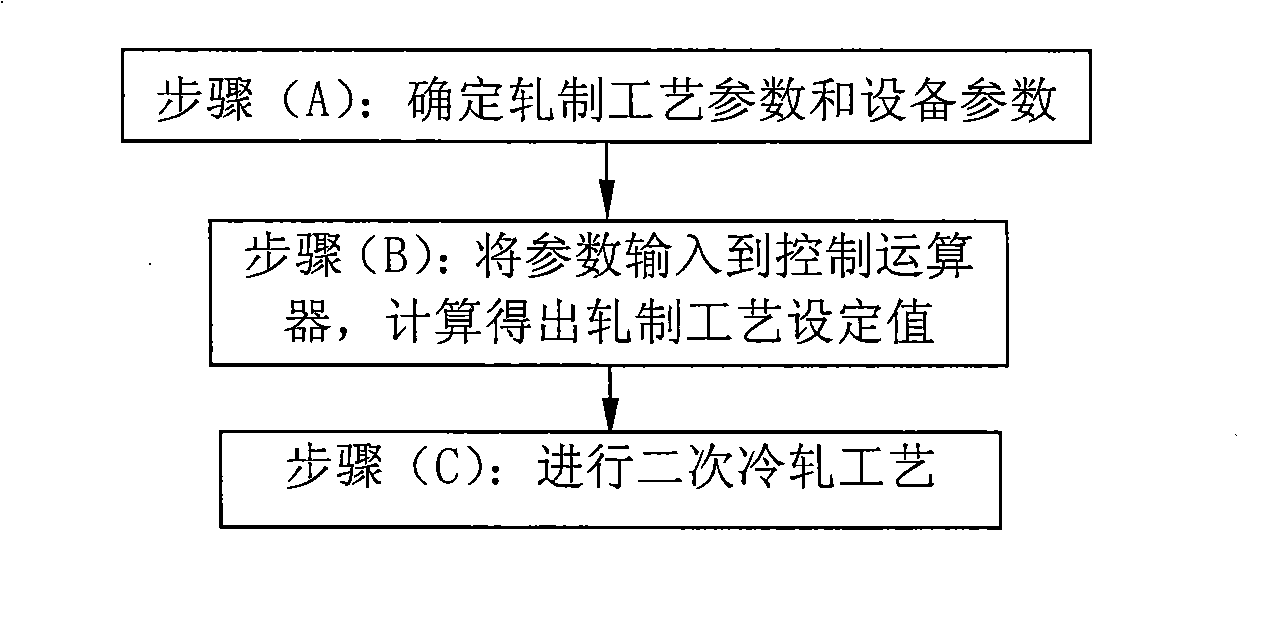

[0073] Figure 4 It is the general flowchart of the leveling method of the strip produced by the secondary cold rolling mill of the present invention, and the leveling method specifically includes the following steps:

[0074] (A) determine the rolling process parameters of the strip to be rolled and the equipment parameters of the cold rolling mill;

[0075] (B) input the parameters determined in the step (A) into the control calculator, and obtain the rolling process setting value according to the established calculation model and the control objective function;

[0076] (C) Carry out a secondary cold rolling process according to the obtained rolling process setting value.

[0077] Wherein the calculation process of step (B) is as follows Figure 5 The steps shown are performed:

[0078] (a) determining the set value of the original surface roughness of the work rolls of the first stand and the second stand;

[0079] (b) determine the elongation distribution coefficient ...

no. 2 Embodiment

[0120] In order to further illustrate the present invention, a high-gloss mirror panel with a material size of 0.20×1200mm and a total elongation of 1.2% is taken as an example to describe the production method and related effects of a specific high-gloss mirror panel on a specific unit.

[0121] First also in step a, the surface roughness of the first and second rack work rolls is set:

[0122] Collect the key rolling process parameters of the high-gloss mirror panel to be rolled, mainly including: the thickness lateral distribution value H of the incoming strip material i ={0.20, 0.20, 0.20, 0.20, 0.20, 0.20, 0.20, 0.20, 0.20, 0.20}; the lateral distribution value L of incoming plate shape i = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; strip width B = 1200mm; elongation setting value ε 0 =1.2%; allowable limit value ξ of elongation distribution coefficient between racks max = 0.75, ξ min =0.25; Strip incoming roughness Ra strip0 =0.35μm; finished strip requires roughness Ra strip1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com