Application of induction heating to control sheet flatness in cold rolling mills

a technology of induction heating and control sheet, which is applied in the field of cold rolling, can solve the problems of inability to provide rolled products, sections of rolled products being cut away and scrapped, and the strip edges are not easily prone to high tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

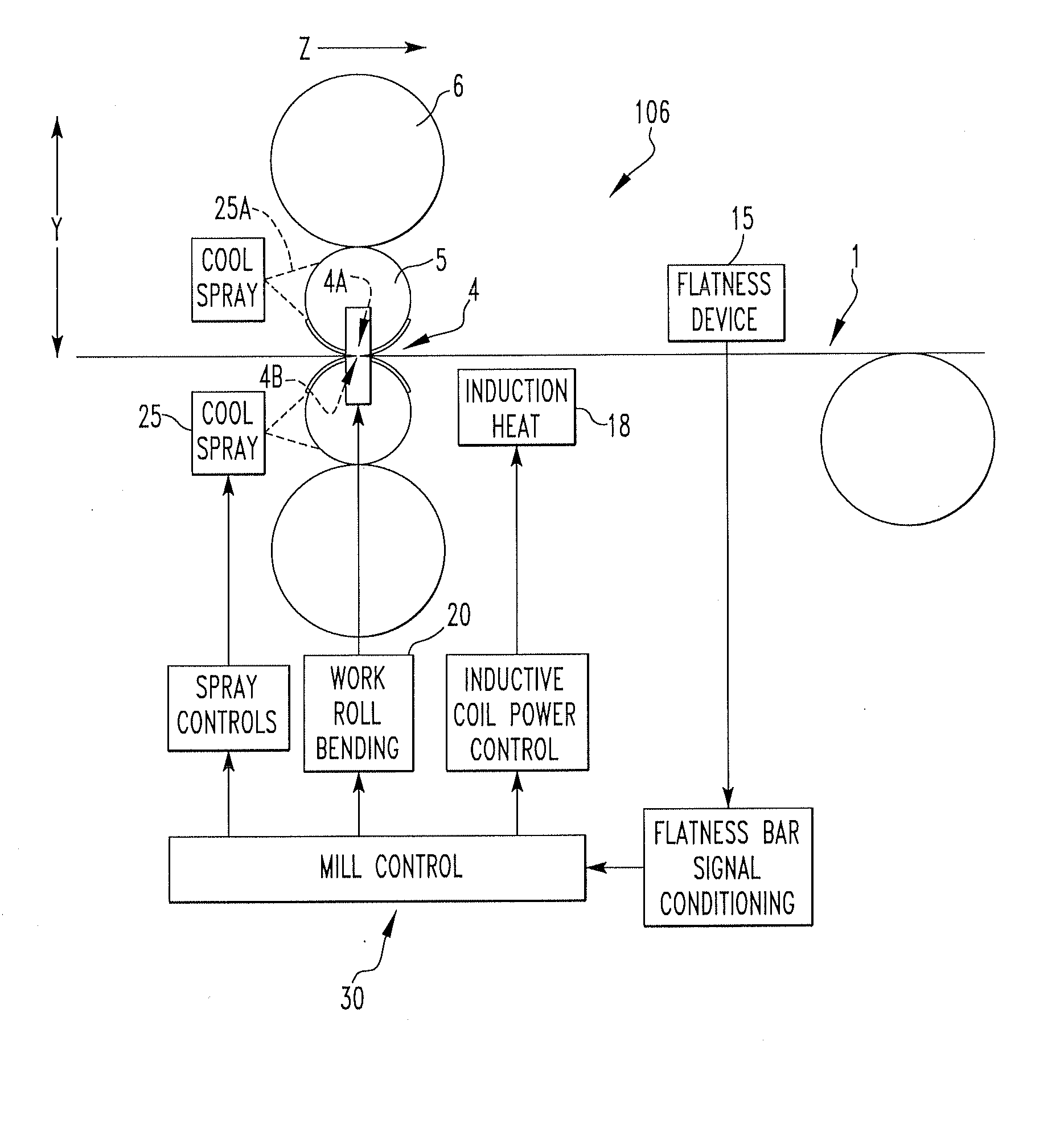

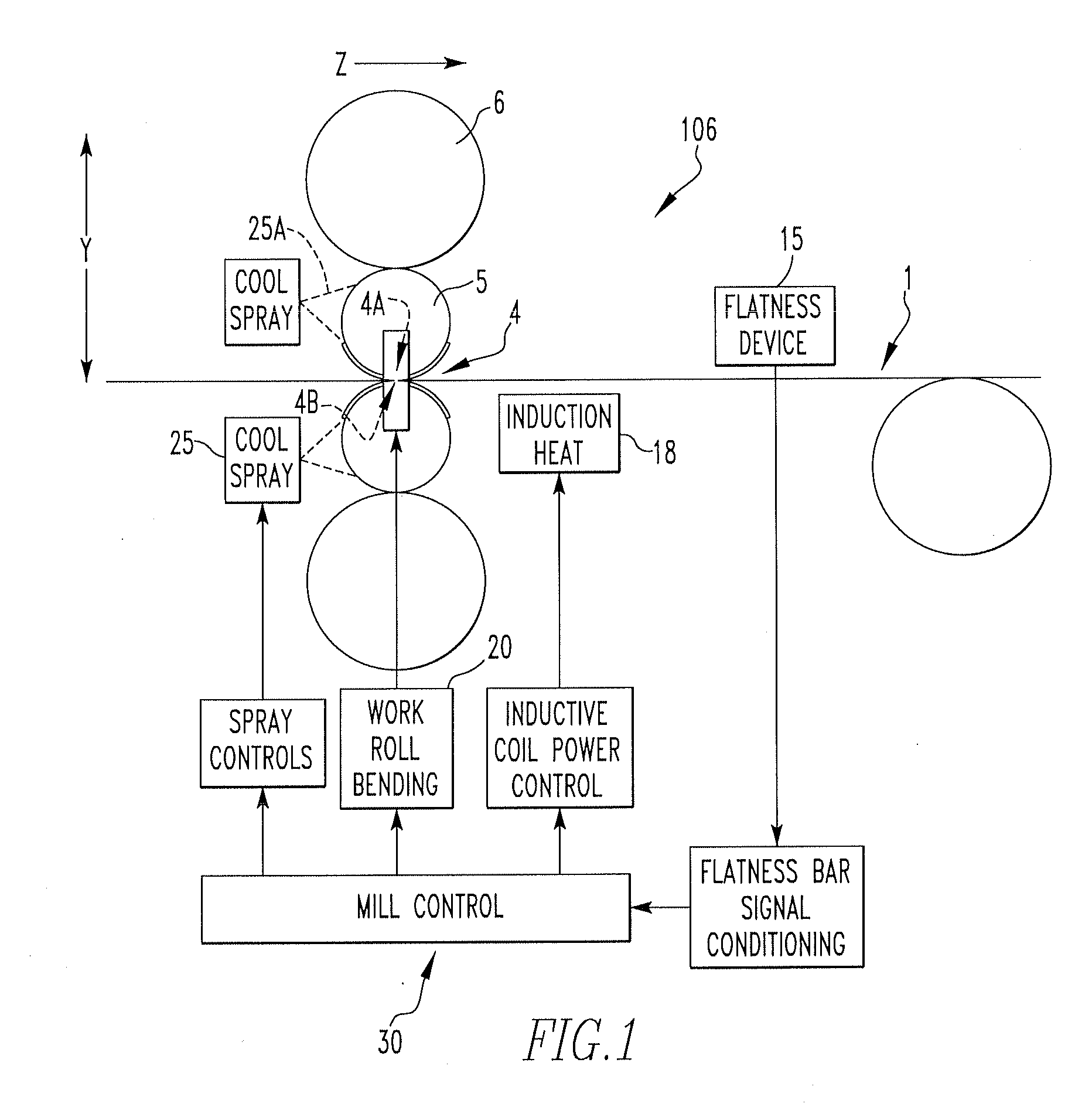

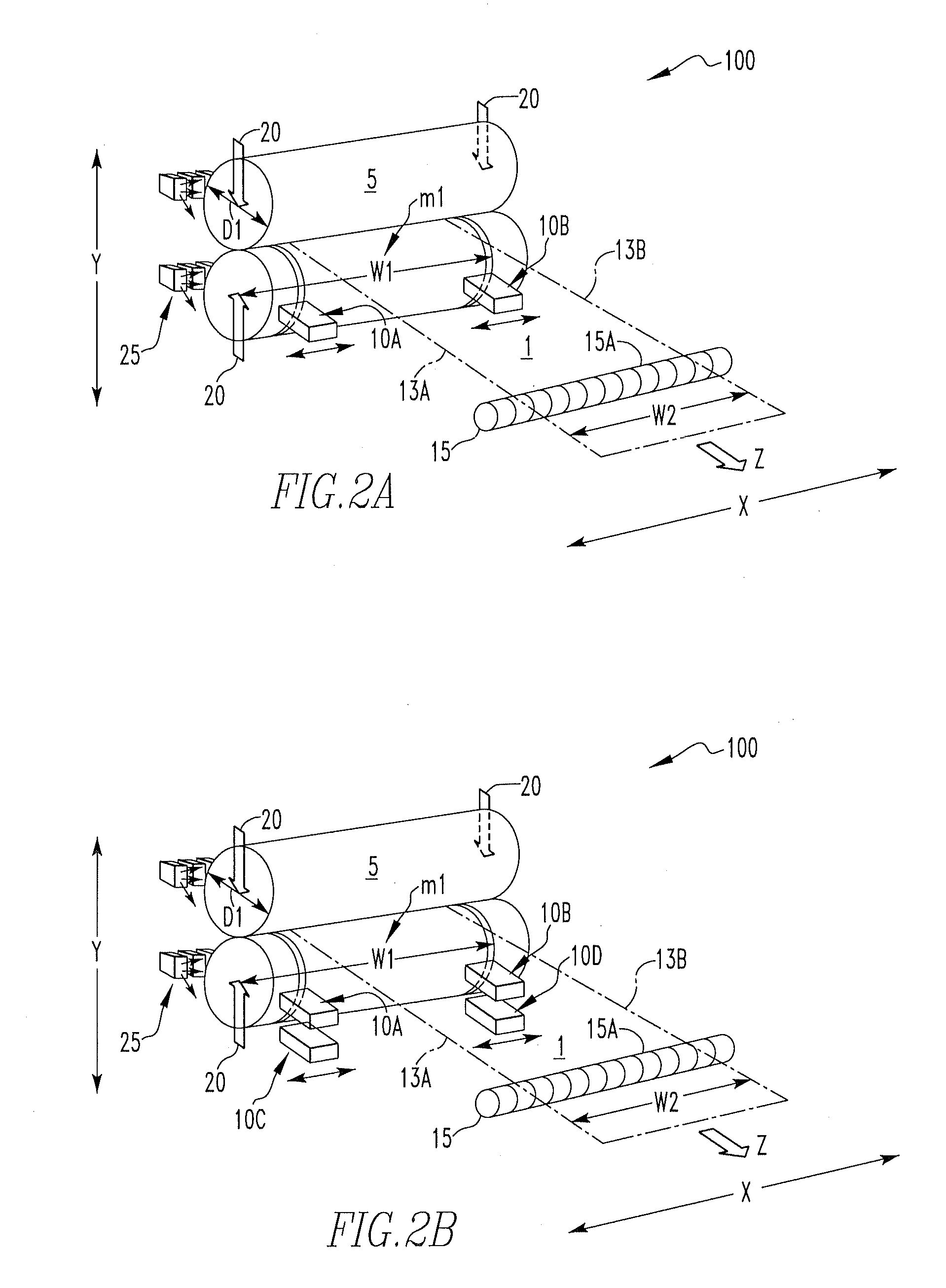

Method used

Image

Examples

examples

[0055]FIG. 4 graphically depicts a tension distribution across the rolled product that is provided by induction heaters corresponding to the edge diameter of a singular work roller, in comparison to the tension distribution provided by a similiarly prepared rolled product without induction heating. Referring to FIG. 4, the vertical axis represents the tension (pounds per square inch) that is measured in the rolled product, and the horizontal axis represents the width of the rolled product, wherein tension measurements were incrementally recorded from a flatness bar in which each zone of the sheet corresponded width of the rolled product. The tension distribution recorded in FIG. 4 is normalized to the nominal coiling tension, which may be on the order of 3000 Psi. The tension distribution depicted in FIG. 4 was produced by an Aluminum Association 3003 series aluminum alloy metal strip rolled by a single stand cold rolling mill from a thickness of approximately 0.035″ to 0.017″ at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com