ec double winding brushless dc motor

A technology of brushless DC motor and double winding, which is applied in the direction of winding, electronic commutation motor control, electrical components, etc. It can solve the problems of interphase winding breakdown and motor failure, and achieve the elimination of high voltage, improvement of drive circuit, and easy The effect of breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below in conjunction with the accompanying drawings.

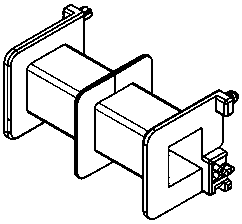

[0018] figure 1 Middle is the schematic diagram of the winding skeleton of the present invention. The two-phase windings are separated through the partition in the middle of the winding frame. The winding frame is integrally molded with polyhexamethylene adipamide containing 30% glass fiber, which can maintain strong strength and rigidity at relatively high temperatures, and has low viscosity and good fluidity.

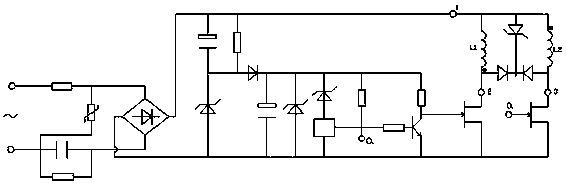

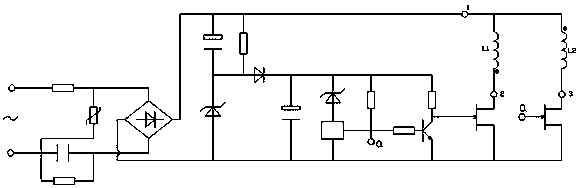

[0019] Such as figure 2 As shown, the driving circuit includes a power input, a protection circuit, a rectifying circuit, a voltage stabilizing circuit, an amplifying circuit, a winding and a trigger circuit for controlling forward and reverse junction field effect transistors, and a winding is arranged between the two windings. protect the circuit. After the power supply is input into the circuit, through the protection circuit, rectification circuit an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com