Control method for cold rolling mill for improving surface quality of strip steel

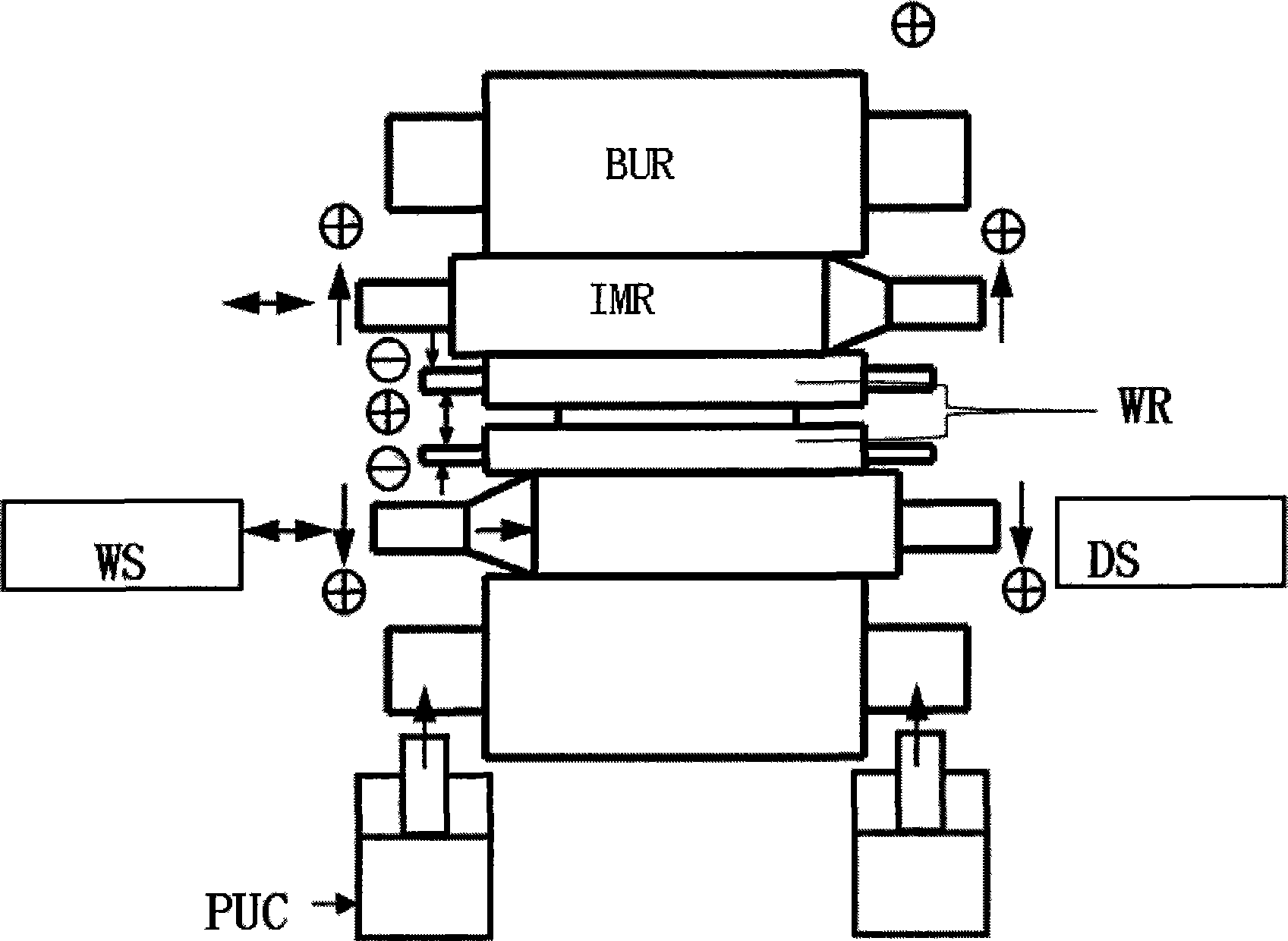

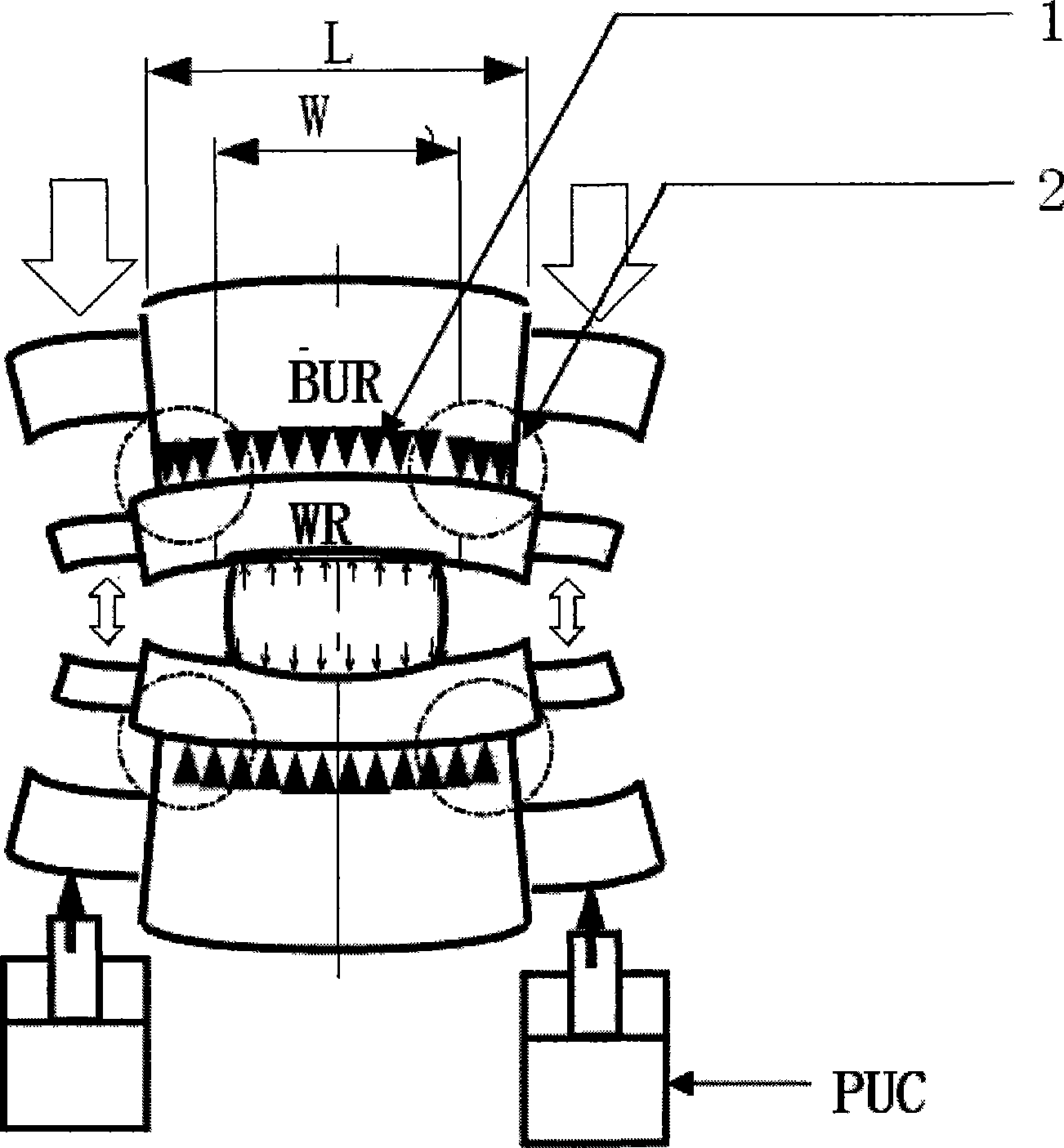

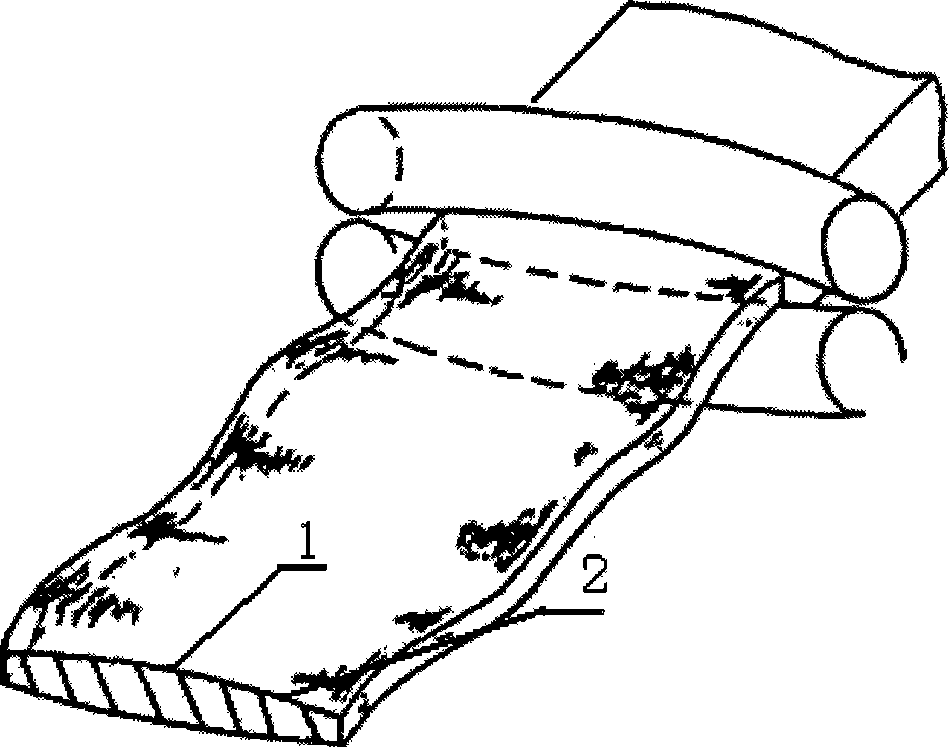

A technology of surface quality and control method, applied in the field of cold rolling in the metallurgical field, can solve problems such as poor plate deformation, and achieve the effects of improving the roll shape, eliminating the roll marks on the outer ring of the steel coil, and simplifying the control model.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] Embodiment 1 (only put into 4 rack bending roll compensation function)

[0107]Production status: The production specification of the rolling mill is 2.5mm / 0.35mm×1411mm, and the rolling speed is 570mpm. Before the weld seam enters the rolling mill, it is prepared for shearing. The side waves are serious, and wrinkling and embossing will occur on both sides of the steel coil after being pressed by the pressure roller of the coiler.

[0108] Adjustment status: For this reason, on the next roll of strip steel with the same specification (2.5mm / 0.35mm×1411mm), put into the 4-stand bending roll compensation function and carry out debugging.

[0109] key parameter:

[0110] a: h5 thickness, determine whether this function is enabled;

[0111] b: The time T in the 1st inertial delay link 1 / (1+Ts), to determine the filtering effect;

[0112] c: MAX(F WR ), the maximum adjustable amount of bending compensation;

[0113] d: KIG, to determine the integration time.

[0114] ...

Embodiment 2

[0122] Embodiment 2 (putting into 4 racks and 5 racks bending roll compensation function)

[0123] Production status: The production specification of the rolling mill is 2.5mm / 0.35mm×1411mm, and the rolling speed is 641.3mpm. The edge of the shape is serious, and wrinkling and embossing will occur on both sides of the steel coil after being pressed by the pressure roller of the coiler. The rolling mill produced stably.

[0124] Adjustment status: put into the 4-stand bending roll compensation function and 5-stand roll bending compensation function respectively, and carry out debugging.

[0125] 1), 4 frame bending roll compensation function adjustment

[0126] key parameter:

[0127] a: h5 thickness, determine whether this function is enabled;

[0128] b: The time T in the 1st inertial delay link 1 / (1+Ts), to determine the filtering effect;

[0129] c: MAX(F WR ), the maximum adjustable amount of bending compensation;

[0130] d: KIG, to determine the integration time. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com