Method for overcoming camber defect in hot rolling process of steel plate

A hot rolling process and camber technology, which is applied in the field of rolling stock processing, can solve the problems of uneven force on the roll body, deformation, and reduce the camber of the intermediate billet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

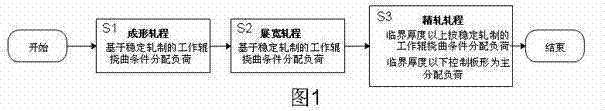

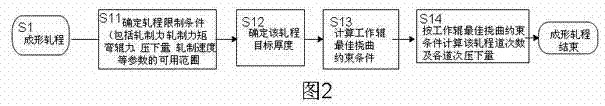

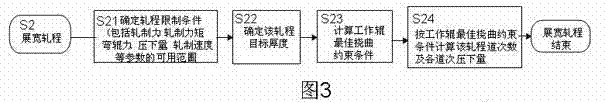

[0086] The invention provides a method for eliminating camber defects in the hot rolling process of steel plates, which is based on the deflection conditions of the work rolls in stable rolling and aims at the different characteristics of the three stages of the hot rolling process of steel plates, namely the forming rolling process and the widening rolling process , Finishing rolling schedule, respectively design the rolling schedule, take the deflection of the work roll in stable rolling as the constraint condition, increase the deflection of the work roll to strengthen the centering of the rolled piece, reduce or even eliminate the deviation of the rolling center line of the rolled piece, In this way, the purpose of eliminating the camber defect is achieved, and at the same time, the shape of the product is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com