Organic solid waste zero-emission resource technology

An organic solid and zero-emission technology, applied in the direction of solid waste removal, etc., can solve the problems that cannot meet the objective situation of resource disposal of organic solid waste, backward process equipment, and unobvious economic benefits, so as to achieve resource utilization and overcome long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

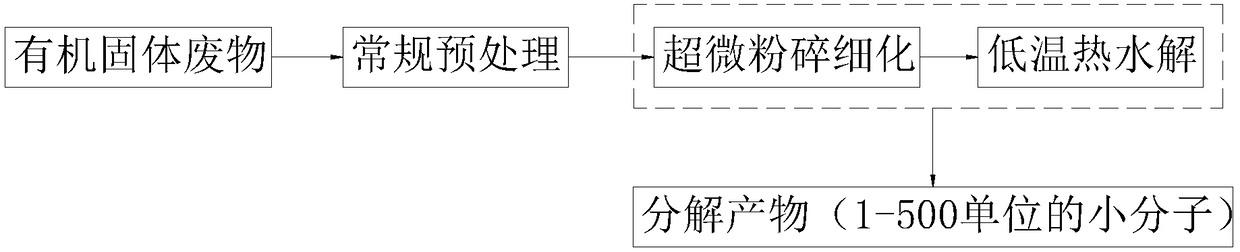

[0016] In order to understand the technical scheme of the present invention more intuitively and completely, the non-limiting feature descriptions are as follows in conjunction with the accompanying drawings of the present invention:

[0017] Such as figure 1 As shown, the organic solid waste zero discharge and recycling process includes the following steps:

[0018] (1) Pretreatment to make the organic solid waste material properties uniform;

[0019] (2) Superfine pulverization and refinement, the material is subjected to secondary pulverization and refinement, and the cell structure of biological macromolecules is initially destroyed;

[0020] (3) Low-temperature thermal hydrolysis, which decomposes organic macromolecules of organic solid waste into small molecular substances.

[0021] Further, in step (1), the pretreatment includes one or more of sorting, coarse crushing, fine crushing, pulping, and homogenization, so that the particle size of the material meets the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com