Pick For Earthworking Machine

a technology for earthworking machines and cutters, applied in the field of cutters, can solve the problems of inefficient operation of picks, high heat generation of the tips, and inefficient heat generation of the tips, and achieve the effects of reducing costs, reducing complexity, and efficient transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

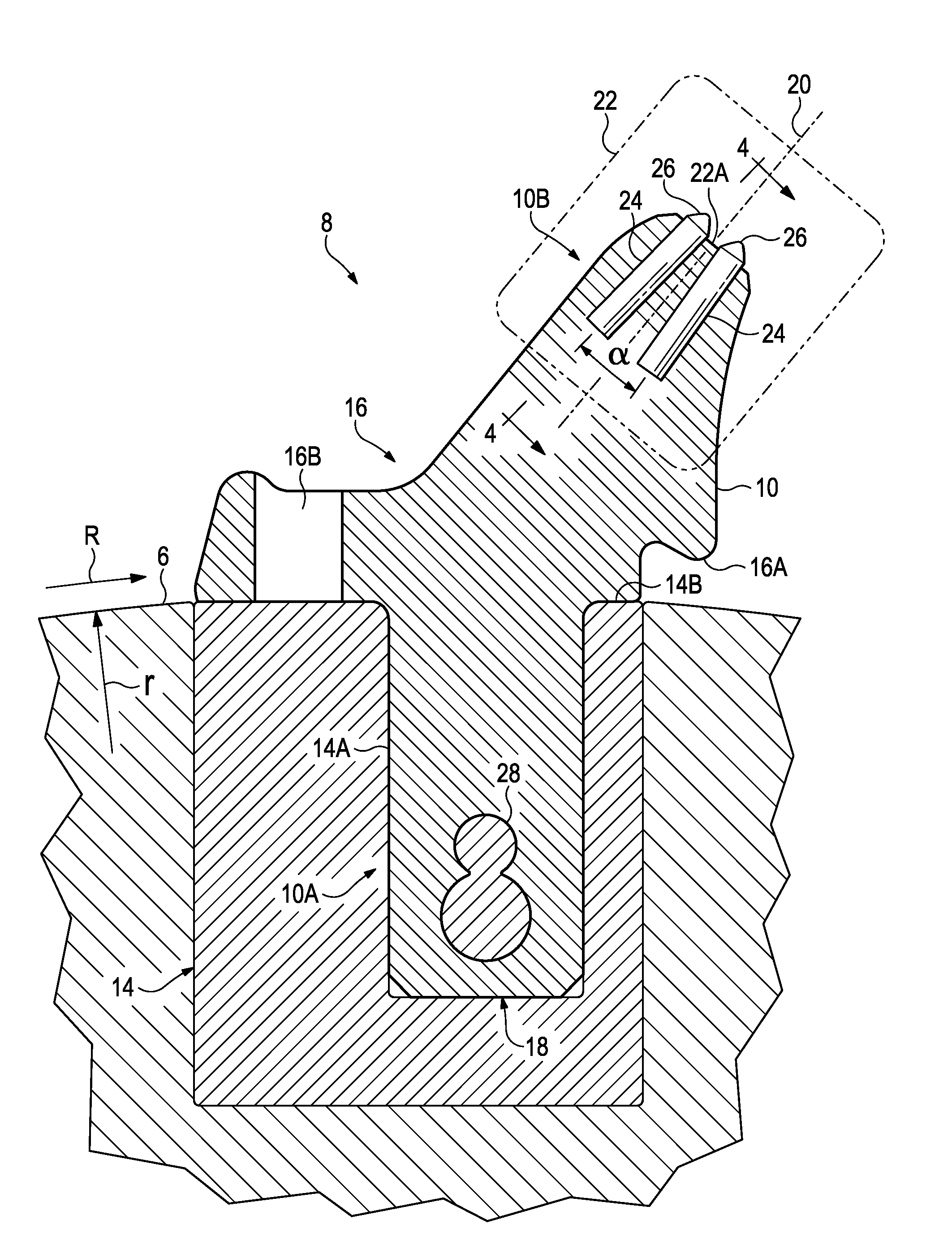

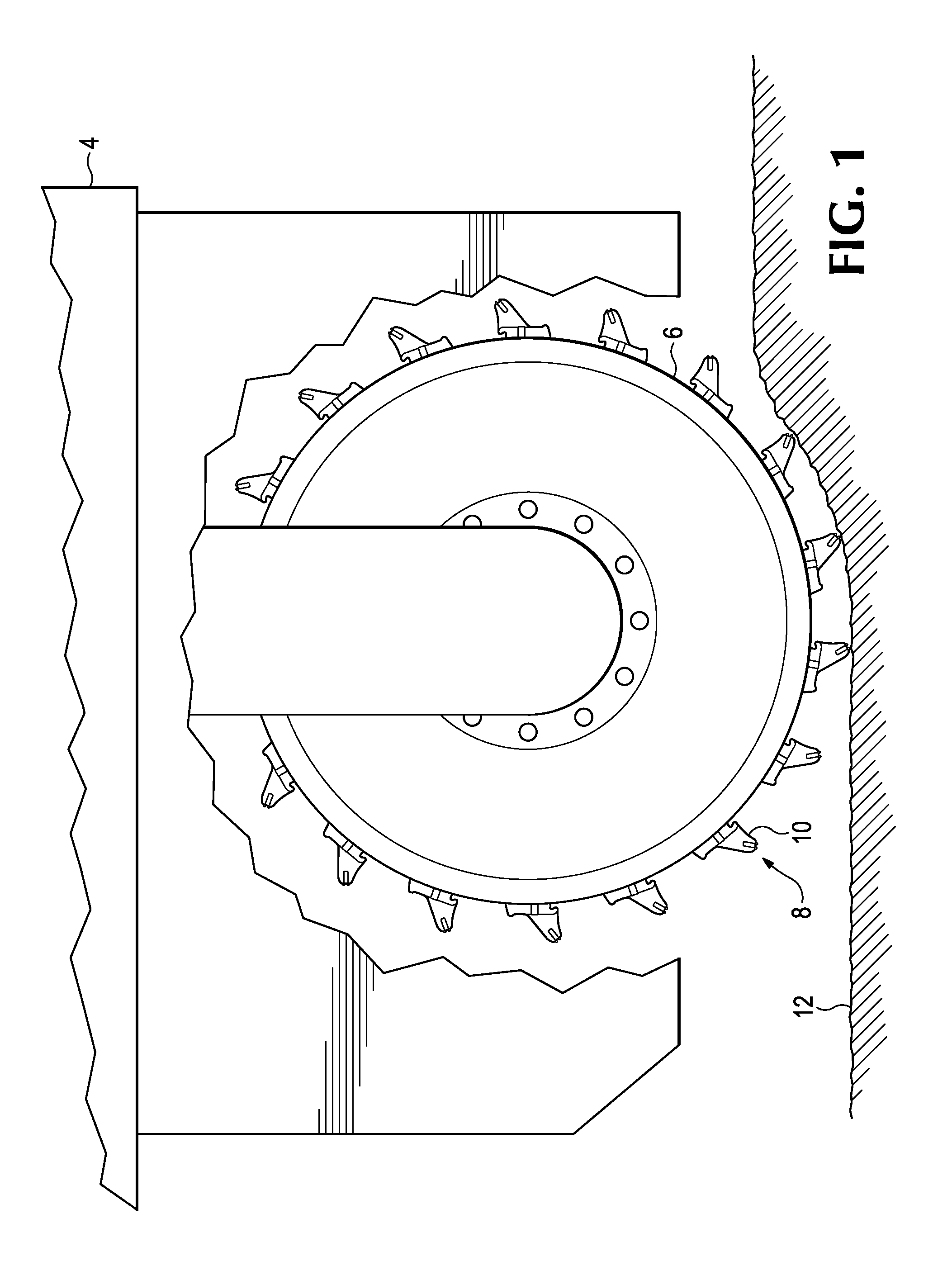

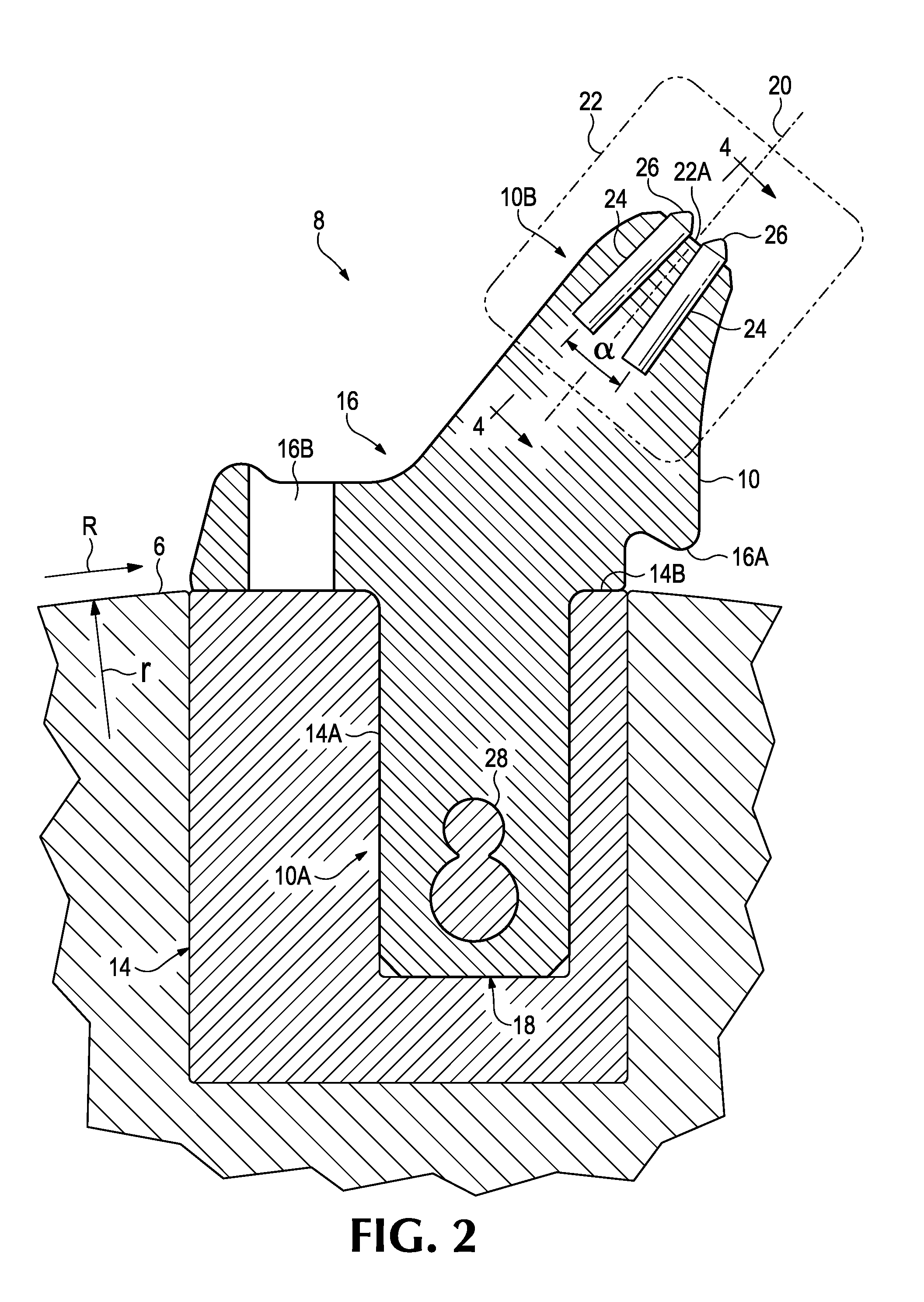

[0021]FIG. 1 depicts an earth working operation including a face miner with pick assemblies for extracting earthen material such as coal in a mining operation. The operation is shown as including a mining machine 4 with a driven drum, roll or cylindrical body 6 mounted with pick assemblies 8 including picks 10 for impacting the ore seam or consolidated earthen material 12 as drum 6 rotates. Picks 10 are mechanically attached or secured to rotating drum or cylindrical body 6. Earthen material 12 to be extracted is typically in a seam and rotating drum 6 passes across the mine face so the picks impact the face and dislodge material from the seam in manageable portions. Picks 10 impinge on the material with adequate speed and force to fracture the material.

[0022]The spacing of the picks determines the size of the dislodged material, but also is a factor in stress on individual picks and heating of components. The mined material is typically dropped onto a conveyor and transported away ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com