Variable convexity working roll for rolling plates, sheets and strips

A work roll and variable crown technology, applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problem that the no-load roll gap does not have the ability to control the high-order crown, the crown adjustment ability declines rapidly, and the crown control Insufficient ability and other problems to achieve the effect of enhancing the overall shape control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

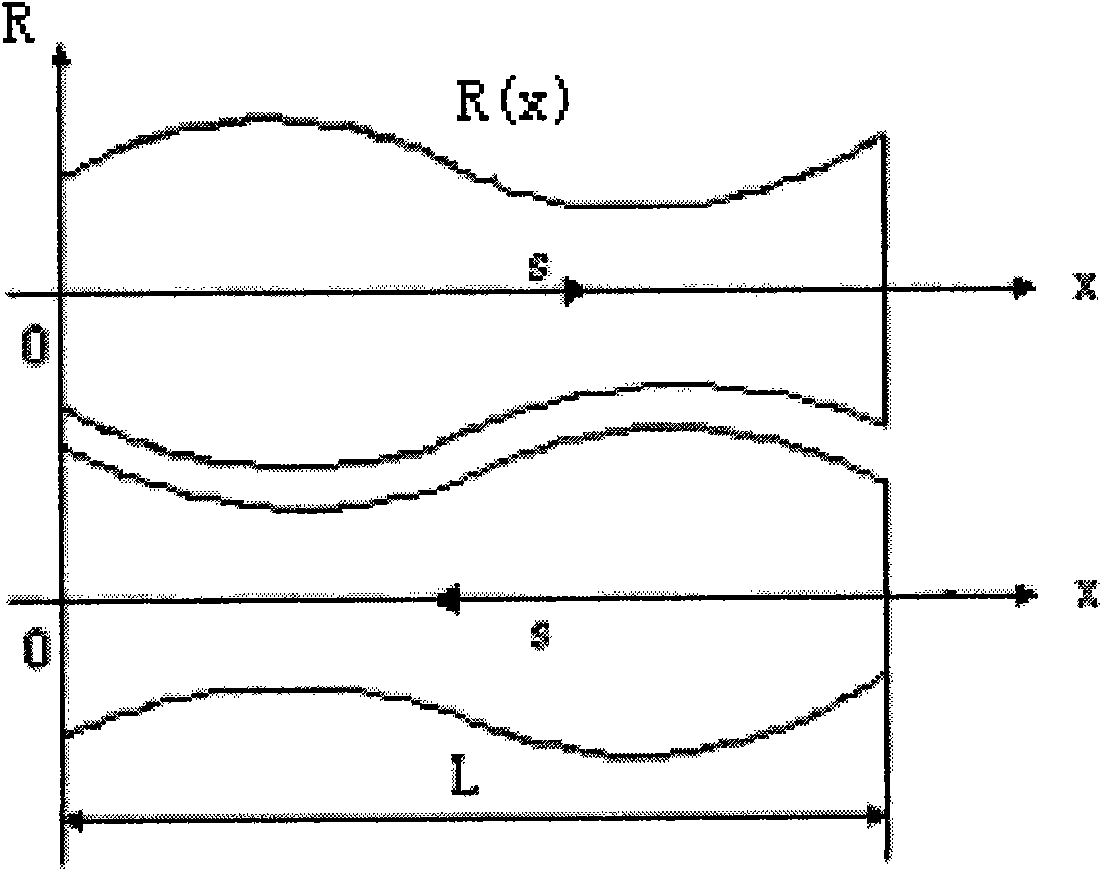

[0070] An advanced variable crown work roll shape that can maintain a linear relationship between the no-load roll gap crown and the amount of roll shifting, while ensuring the secondary crown control capability of narrow strip steel, while providing a certain degree of high crown crown control ability. The radius function equation of the work roll profile is:

[0071] R ( x ) = R 0 + a 1 x + a 2 x 2 + a 3 x 3 + a 4 sin [ πα 90 L ( x - L / 2 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com