A method for configuring the crown of work rolls in a hot tandem mill

A technology of hot continuous rolling mill and configuration method, which is applied in the field of steel rolling, and can solve the problems of not considering the influence of bad plate shape, not having clear design criteria and basis, and not giving the configuration method of CVC work roll crown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

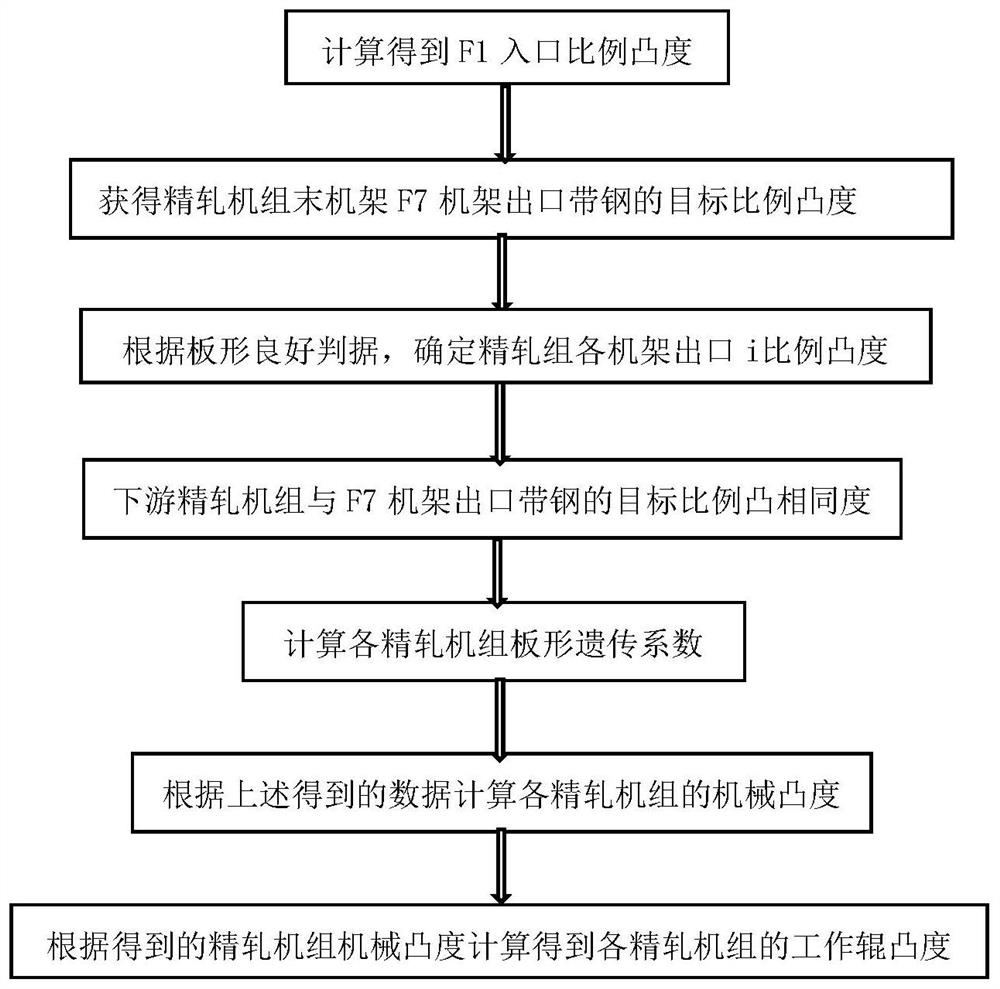

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0076] The main rolling material grade of the 1250mm hot rolling unit in a steel plant is cold-rolled base material, the thickness of the hot continuous rolling entrance is 38mm, and the exit thickness of each stand is 20mm, 15mm, 10mm, 7mm, 5mm, 4mm, 3mm.

[0077] Table 1 The entrance thickness of hot continuous rolling is 38mm, and the exit thickness of each stand

[0078] frame F1 F2 F3 F4 F5 F6 F7 Exit thickness 20mm 15mm 10mm 7mm 5mm 4mm 3mm

[0079] (1) Calculation of the entrance strip crown C of the F1 stand of the finishing mill 0 The formula is:

[0080]

[0081] where C shown in Equation I int For the given F, B, C WR and C WB The loaded roll gap crown obtained by finite element calculation;

[0082] F is the rolling force of rough rolling; B is the exit strip width of the last pass of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com