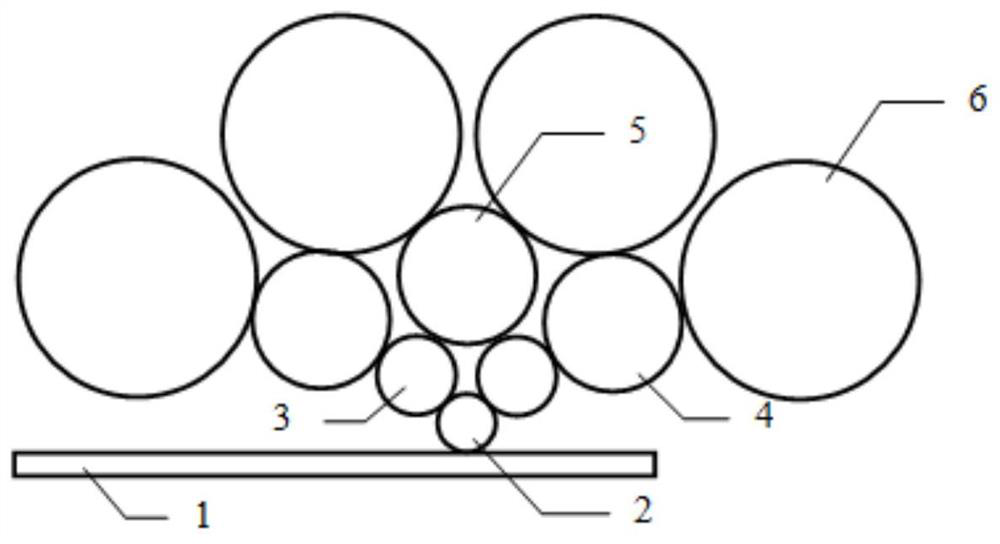

Roll shape of driven roll of second intermediate roll of Sendzimir mill

A technology of driven rolls and intermediate rolls, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of affecting the shape control of silicon strip steel, increasing the cost of roll use, and insufficient crown retention ability, etc., to achieve reinforced plate Shape control ability, extended service life, and improved crown retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

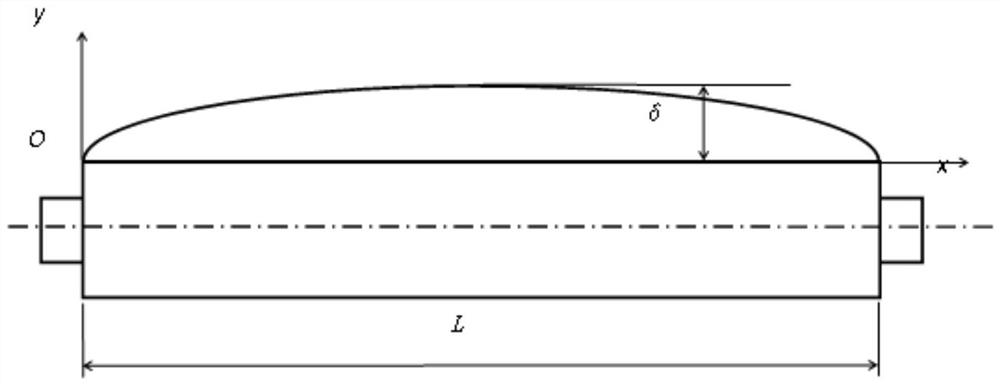

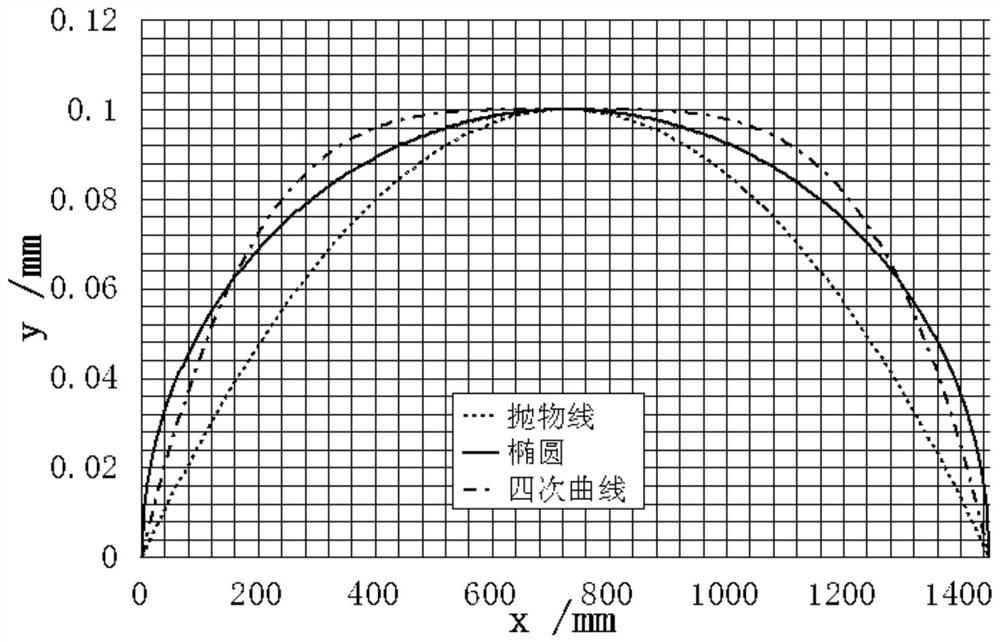

[0028] The length of the driven roll 5 of the second intermediate roll of the Sendzimir mill is L=1450mm, the crown is 2δ=0.2mm, the roll shape curve is a parabola, and the parabola equation is y=0.1-0.1 / 725 2 *(x-725) 2 . Please see attached Figure 4 , Compared with the arc roll shape, the contact stress peak with the first intermediate roll is reduced by about 10MPa, which helps to reduce the wear of the roll, prolong the service life of the roll, and improve the shape control ability of the rolling mill.

Embodiment 2

[0030] The roll surface length of the driven roll 5 of the second intermediate roll of the Sendzimir mill is L=1550mm, the crown is 2δ=0.2mm, the roll shape curve is a parabola, and the parabola equation is y=0.1-0.1 / 775 2 *(x-775) 2 . Compared with the arc roll shape, the contact stress peak with the first intermediate roll is reduced by about 12MPa, which helps to reduce roll wear, prolong the service life of the roll, and improve the shape control ability of the rolling mill.

[0031] Please see attached figure 2 and attached image 3 , a roll shape of the driven roll of the second intermediate roll of a Sendzimir mill, the roll shape of the driven roll 5 of the second intermediate roll is an elliptic curve, and the axis of the driven roll 5 is the x-axis, and the driven roll 5 is driven. The radial direction of the roller 5 is the y-axis, and the vertex of the end of the roller body of the driven roller 5 is the origin, and the convexity curve equation of the elliptic ...

Embodiment 3

[0033] The length of the driven roll 5 of the second intermediate roll of the Sendzimir mill is L=1450mm, the crown is 2δ=0.2mm, the roll shape curve is an elliptic curve, and the elliptic curve equation is y=0.1*sqrt(1-(( x-725) / 725) 2 ). Compared with the arc roll shape, the contact stress peak with the first intermediate roll is reduced by about 50MPa, which helps to reduce the wear of the roll, prolong the service life of the roll, and improve the shape control ability of the rolling mill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com