Three-dimensional curve flexible shaping device using bend flexible roller

A three-dimensional curved surface and flexible forming technology, which is applied in the field of plastic forming equipment and three-dimensional curved surface flexible forming device, can solve the problems of poor processing quality, low production efficiency, and long processing cycle, so as to improve production efficiency, save manpower and reduce cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

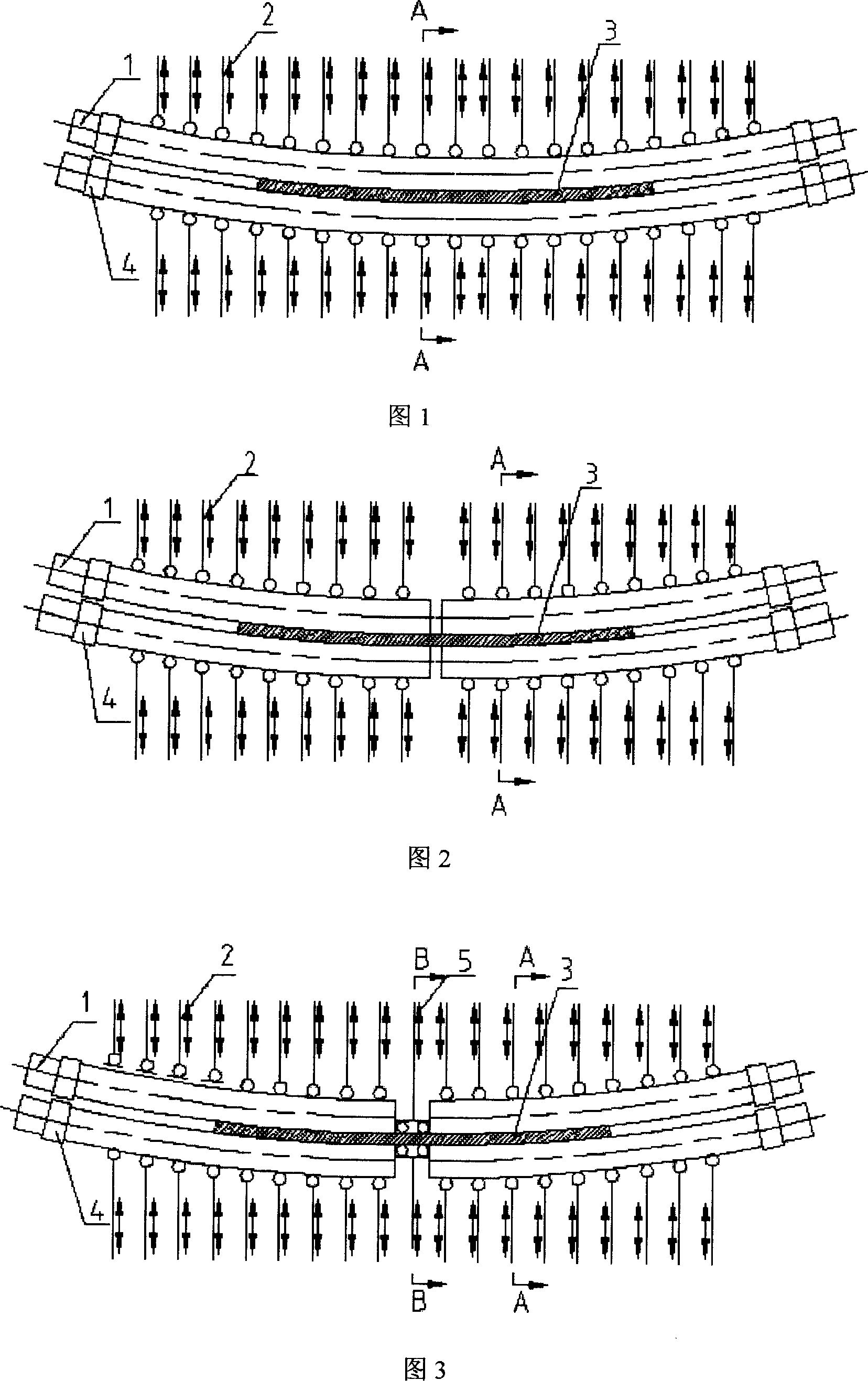

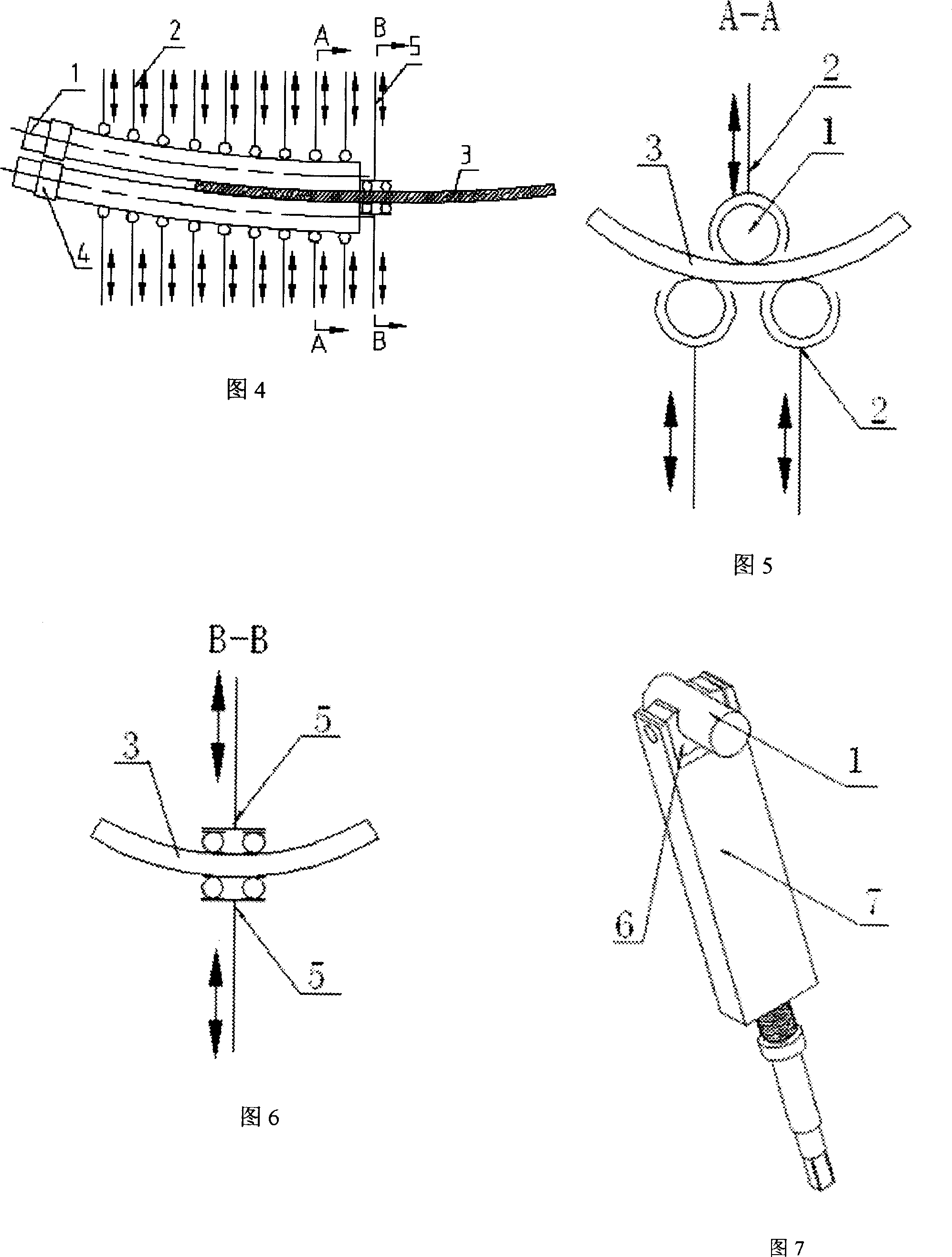

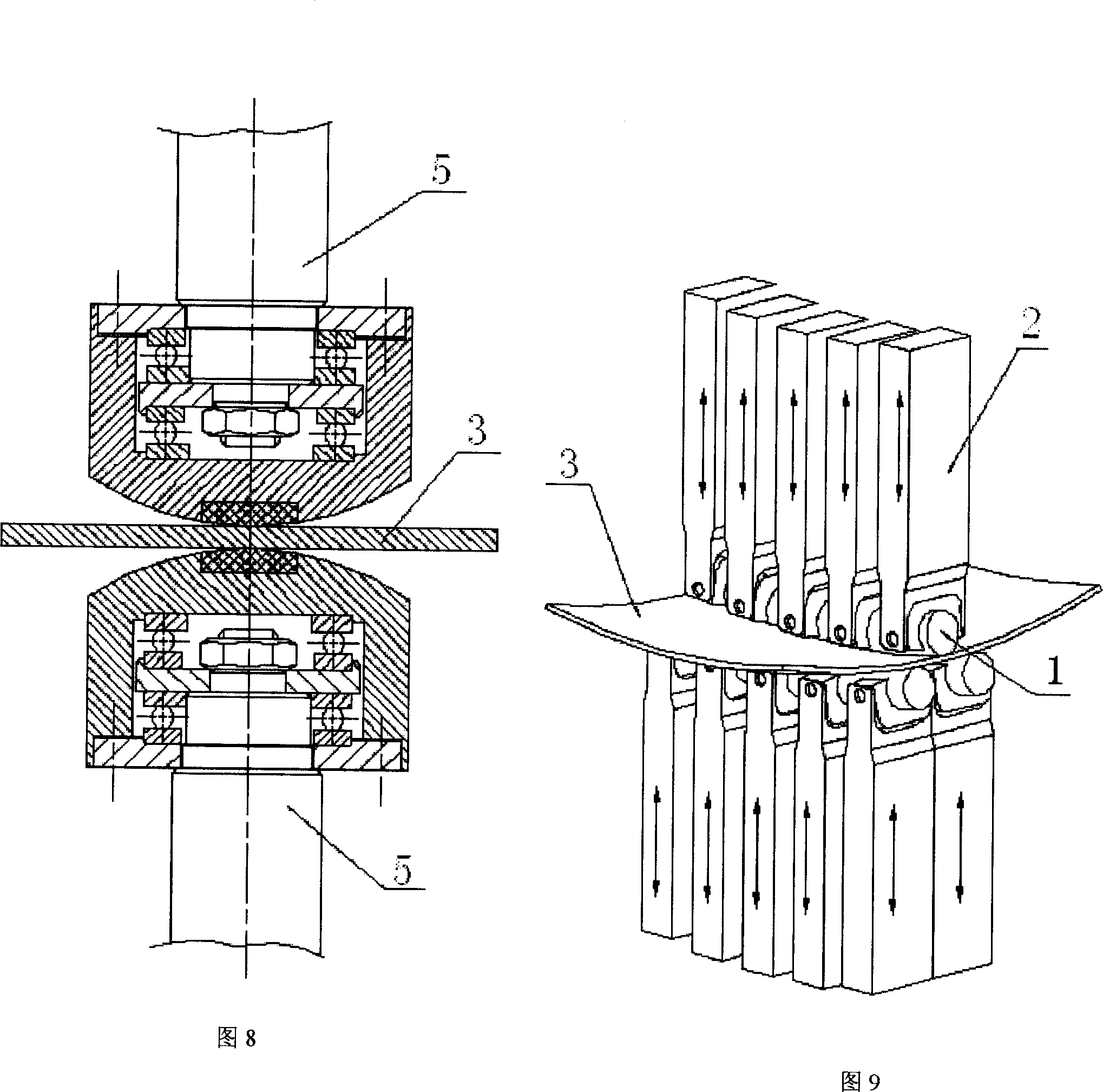

[0023] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings, but the arrangement of the working rolls is not limited to the arrangement in the accompanying drawings.

[0024] Referring to the embodiment of Fig. 1, according to the required three-dimensional shape of the plate, the adjustment rod 7 of the adjustment mechanism 2 is adjusted by manual control or numerical control system to make the open bearing 6 pull or press the flexible work roll to make it bend and deform; at one end of the flexible work roll Or both ends can be provided with expanders, so that it can freely expand and contract during shape adjustment, and can be fixed after shape adjustment to prevent relative displacement in the axial and circumferential directions. At the same time, in order to make the deformation of the flexible work rolls easier, the lower frame of the equipment can move al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com