Manufacture method of austenitic stainless steel with good polishing performance

A technology of austenitic stainless steel and manufacturing method, which is applied in the field of austenitic stainless steel manufacturing, and can solve the problems that the polishing performance of materials cannot be fundamentally improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

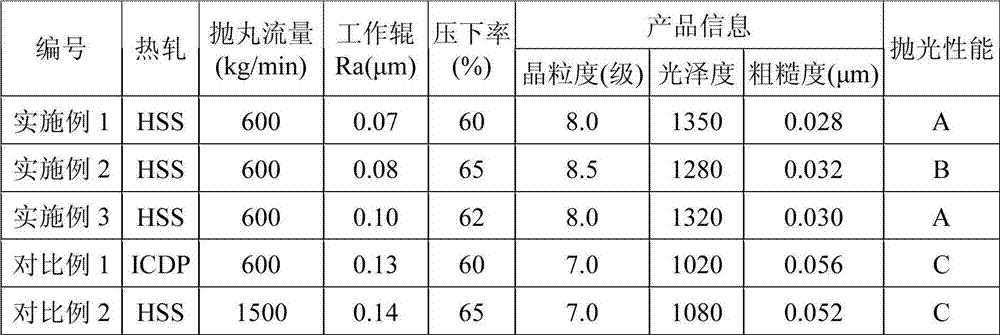

Examples

Embodiment 1

[0031] This embodiment provides an austenitic stainless steel plate with excellent polishing performance, and its manufacturing method comprises the following steps:

[0032] Hot rolling: using HSS rolls, through width change, and hot rolling and rolling mixed weaving, the raw material slab is hot rolled and rolled to obtain hot rolled stainless steel;

[0033] Hot-rolled annealing: performing continuous annealing on the hot-rolled stainless steel at 980-1040°C to obtain a hot-rolled and annealed stainless steel plate;

[0034] Pickling after hot-rolling and annealing: adopt the continuous pickling process of scale breaking-shot blasting-mixed acid to pickle and remove scale on the stainless steel plate after the hot-rolling and annealing, wherein the flow rate of shot blasting is controlled at 600kg / min to obtain hot-rolled Annealed and pickled stainless steel;

[0035] Cold rolling: use a cold rolling mill to cold-roll the stainless steel plate after the hot-rolled annealin...

Embodiment 2

[0040] This embodiment provides an austenitic stainless steel plate with excellent polishing performance. Its manufacturing method is basically the same as that of Embodiment 1, except that the total reduction rate during cold rolling is 65%, and the last 2 passes of the cold rolling mill Work rolls with a roughness of 0.08 μm were used.

Embodiment 3

[0042] This embodiment provides an austenitic stainless steel plate with excellent polishing performance. Its manufacturing method is basically the same as that of Embodiment 1, the difference is that the total reduction rate during cold rolling is 62%, and the last 2 passes of the cold rolling mill Work rolls with a roughness of 0.1 μm are used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com