Magnesium alloy plate rolling parameter monitoring and fault diagnosing system and method

A fault diagnosis system and parameter monitoring technology, applied in metal rolling, metal rolling, length measuring devices, etc., can solve the problems of reducing product production efficiency, scientific decision-making needs to be improved, and low automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The invention will be described in detail below in conjunction with the accompanying drawings.

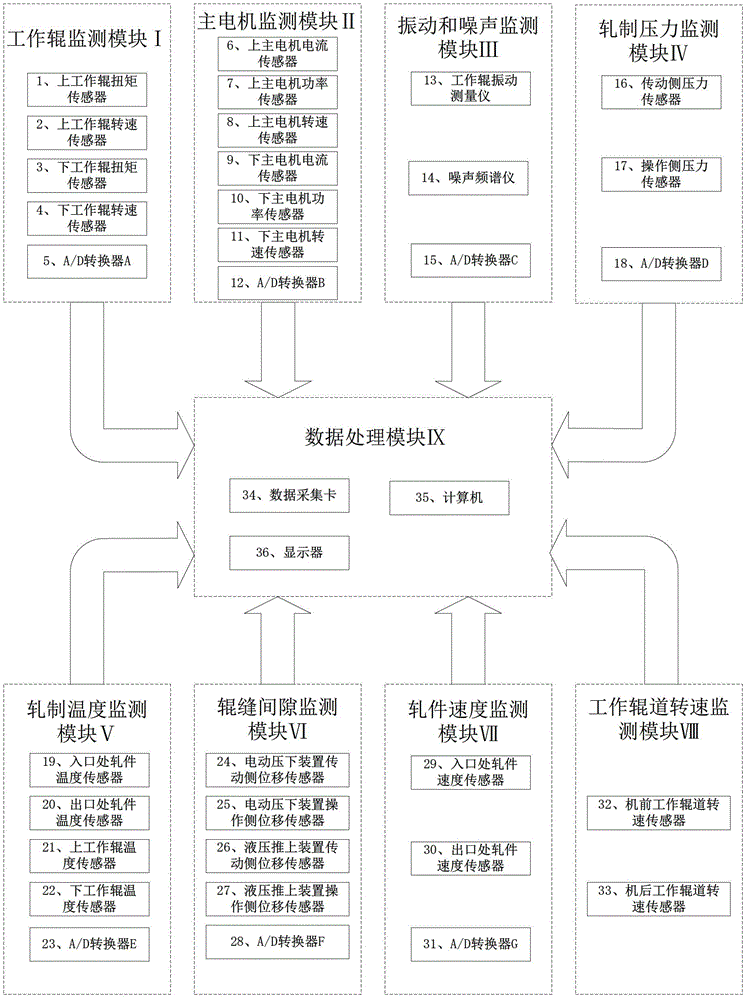

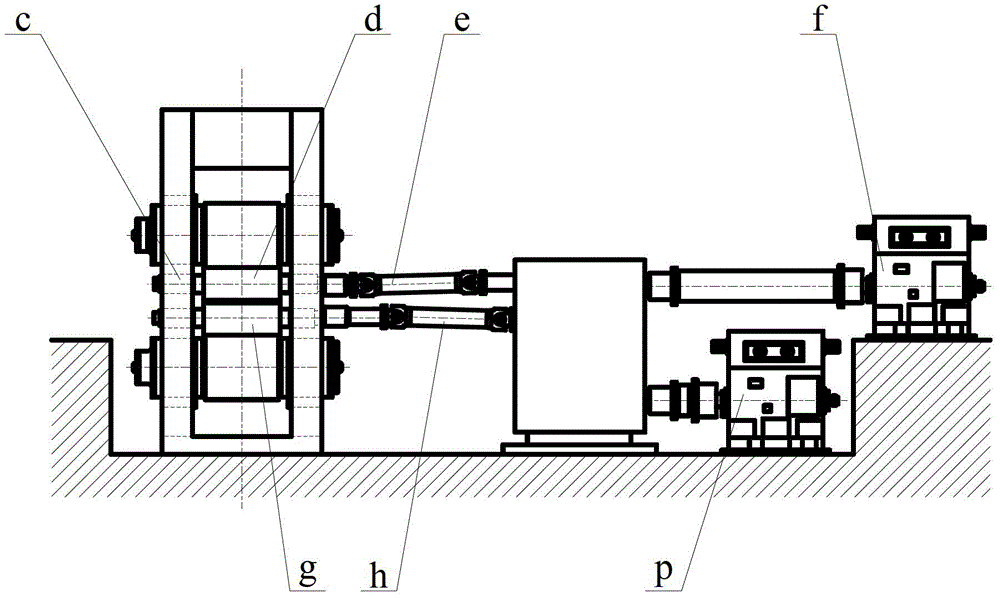

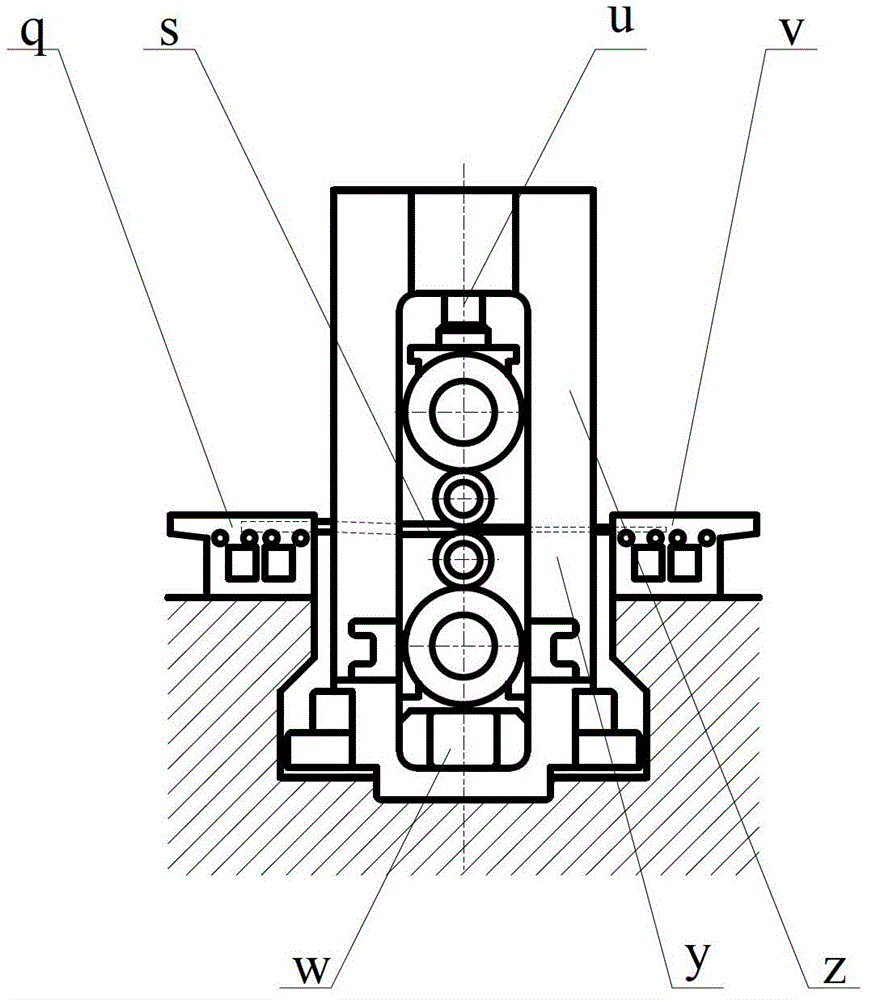

[0072] combined with figure 1 As shown in accompanying drawing 3, a magnesium alloy plate rolling parameter monitoring and fault diagnosis system of the present invention consists of a work roll monitoring module I, a main motor monitoring module II, a vibration and noise monitoring module III, and a rolling pressure monitoring module IV , Rolling temperature monitoring module Ⅴ, roll gap monitoring module Ⅵ, rolling piece speed monitoring module Ⅶ, working roller speed monitoring module Ⅷ, data processing module Ⅸ and rolling mill z. The working roll monitoring module I, main motor monitoring module II, vibration and noise monitoring module III, rolling pressure monitoring module IV, rolling temperature monitoring module V, roll gap monitoring module VI, rolling piece speed monitoring module VII and The working roller speed monitoring module Ⅷ is installed in the correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com