Work roll with steel rim drop-control and flat degree control

A work roll and flatness technology, which is applied in the direction of manufacturing tools, rolls, metal rolling, etc., can solve the problems of small diameter of work rolls, shape defects at the edge of strip steel, easy deformation, etc., to reduce the weight of rolls and save energy. Roll cost and effect of improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

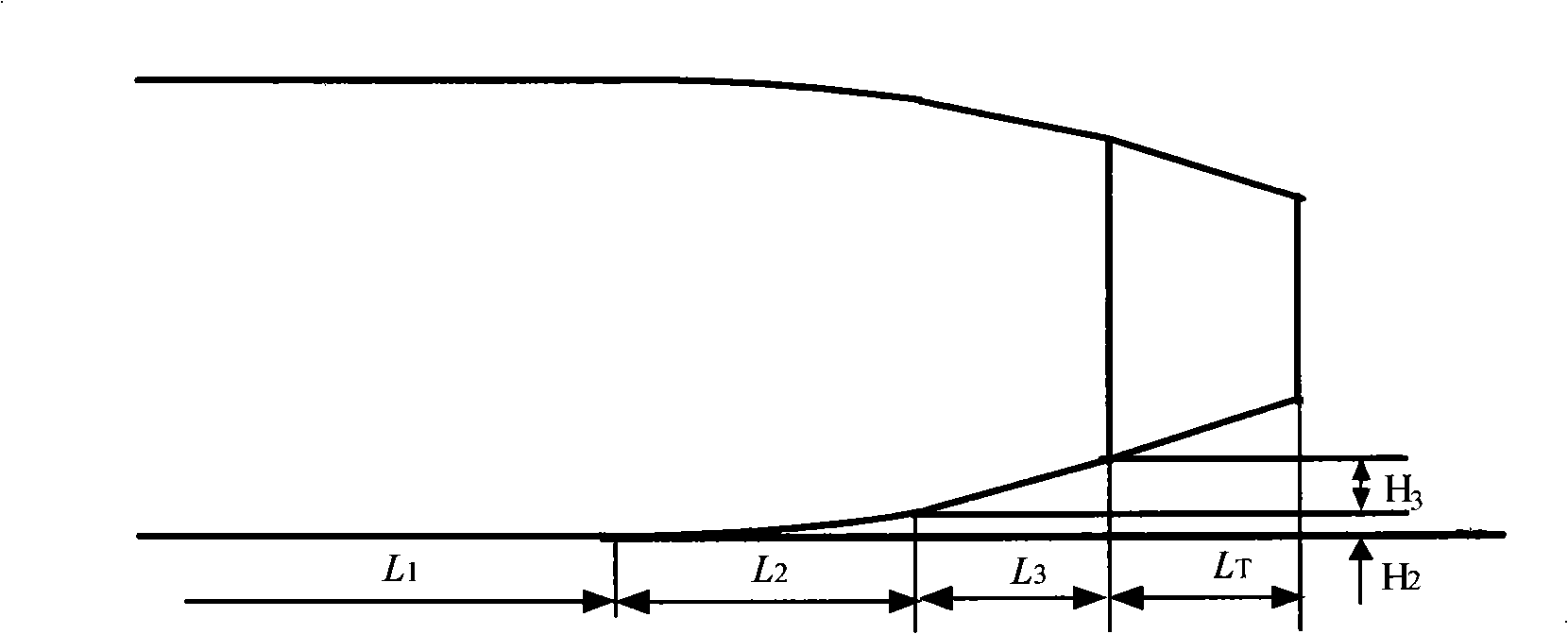

[0034] A work roll that takes into account strip edge drop control and flatness control {it can be called EDW (Edgedrop control work roll) edge drop control work roll}, refer to figure 1 , including flat roll section (length L 1 ), edge drop control curve process section (length L 2 ), edge drop control tangent process section (length L 3 ) and structural taper section (length L T ); Among them, the edge drop control curve process section is tangent to the flat roll section and the edge drop control tangent process section respectively, and the edge drop control tangent process section intersects with the structural taper section, which has the characteristics of continuously variable taper.

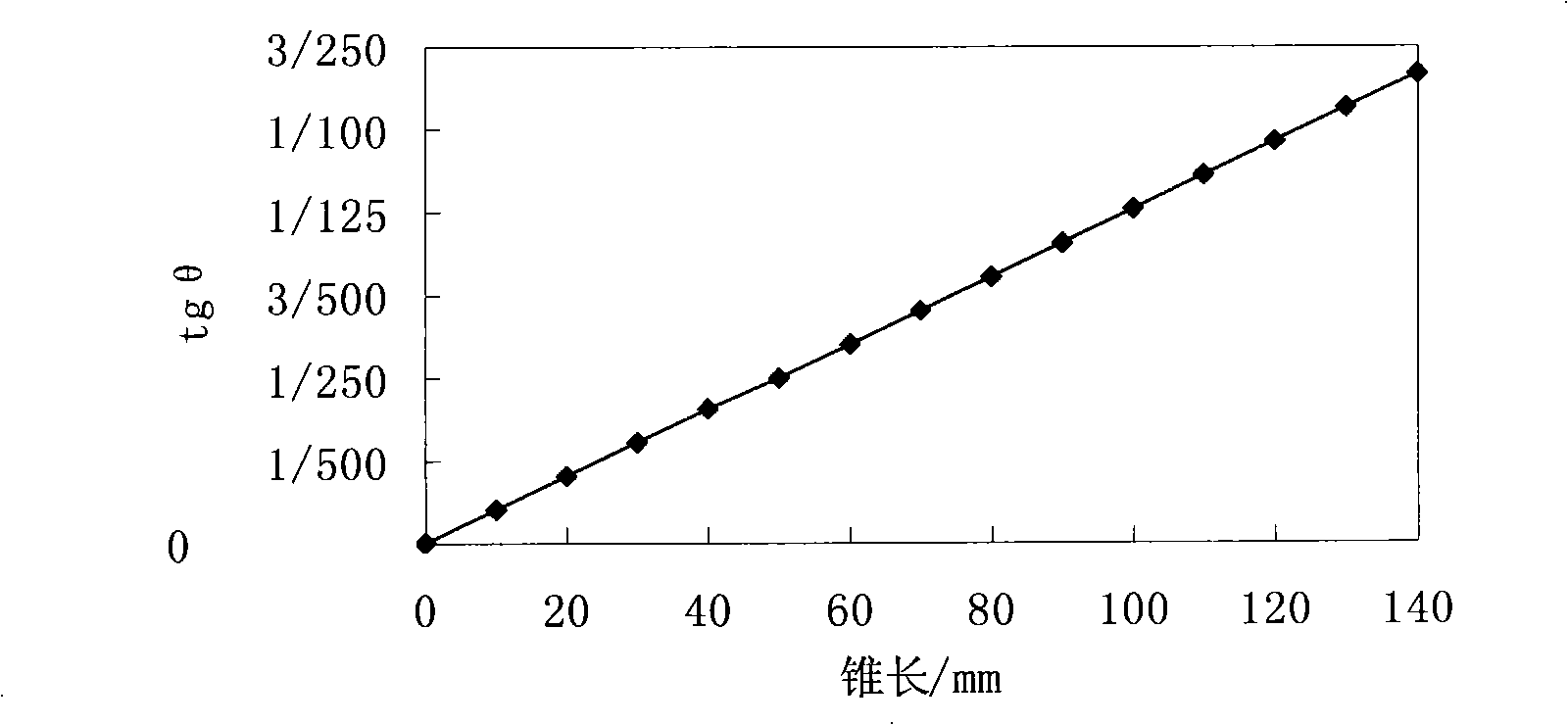

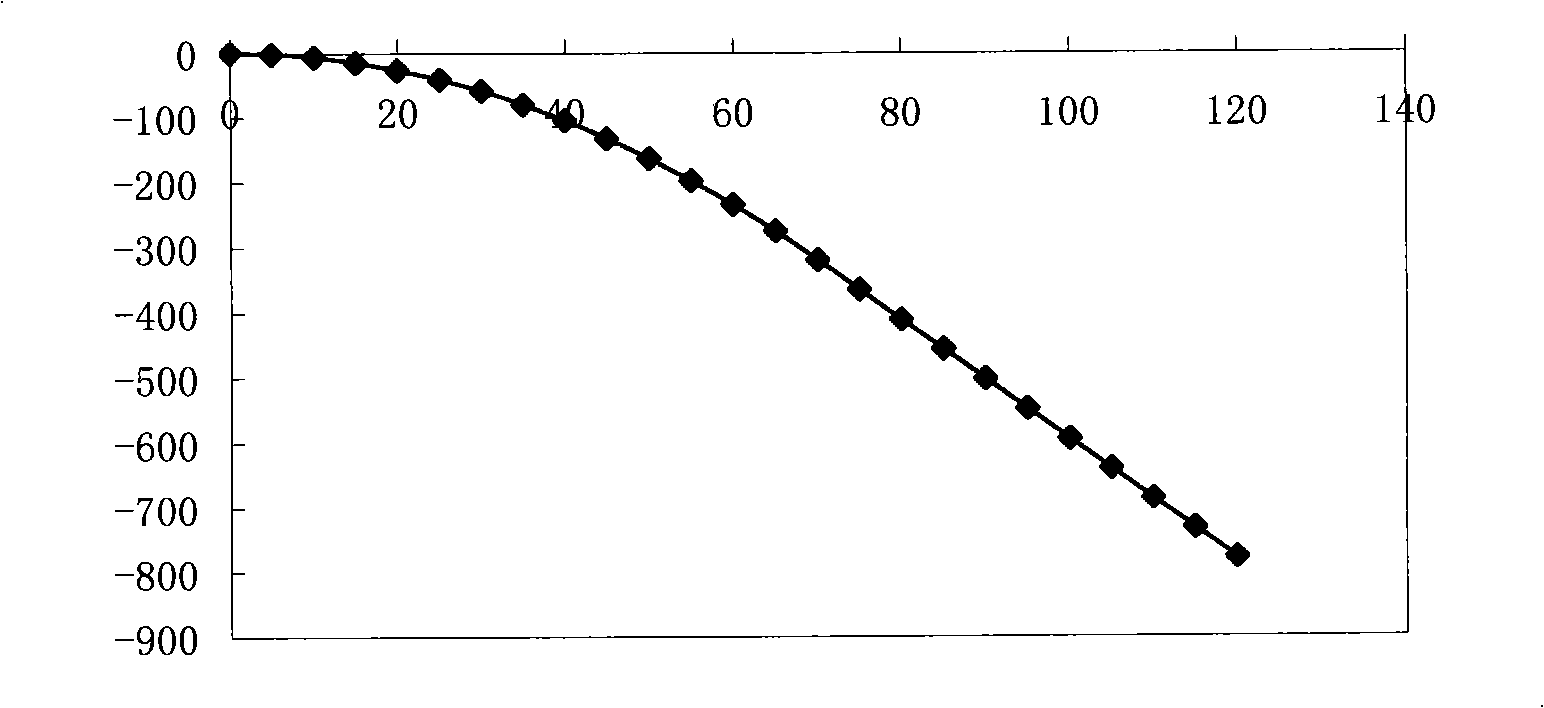

[0035] Taking the starting point of the edge drop control curve process section as the coordinate origin, the function form of the edge drop control curve process section is as follows:

[0036] y = R - R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com