Crosswise thickness-variable strip and preparation method thereof

A technology of variable thickness, plate and strip, applied in the direction of sheet/plate, metal rolling, building elements, etc., can solve the problem of little research on transverse variable thickness plate and strip rolling technology, so as to avoid low production efficiency, The effect of saving metal materials and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The cross-section of the strip to be rolled is as Figure 6 as shown in A6;

[0039] Four kinds of first rolling mills are adopted; the circumference of the cylinder of the upper work roll of the first kind of first rolling mill is provided with a protrusion, and the circumference of the cylinder of the lower work roll is provided with a groove; There is a protrusion and a groove on the circumference of the cylinder of the upper work roll, and a protrusion and a groove are provided on the circumference of the cylinder of the lower work roll; the cylinder of the upper work roll of the third type of first rolling mill There is one bulge and two grooves on the circumference, two bulges and one groove on the circumference of the cylinder of the lower working roll; There are two protrusions and a groove, and there is a protrusion and two grooves on the circumference of the cylindrical surface of the lower work roll; the roll gaps of the four first rolling mills respectively...

Embodiment 2

[0056] The structure of the upper and lower work rolls of the first rolling mill adopted is the same as the first rolling mill of the first kind in embodiment 1; the roll gap forms a U-shaped curve structure; the plate and strip to be rolled is carried out transition rolling with the first rolling mill, and Form a middle plate strip with a special-shaped structure in the middle, and the special-shaped structure is a U-shaped curve structure;

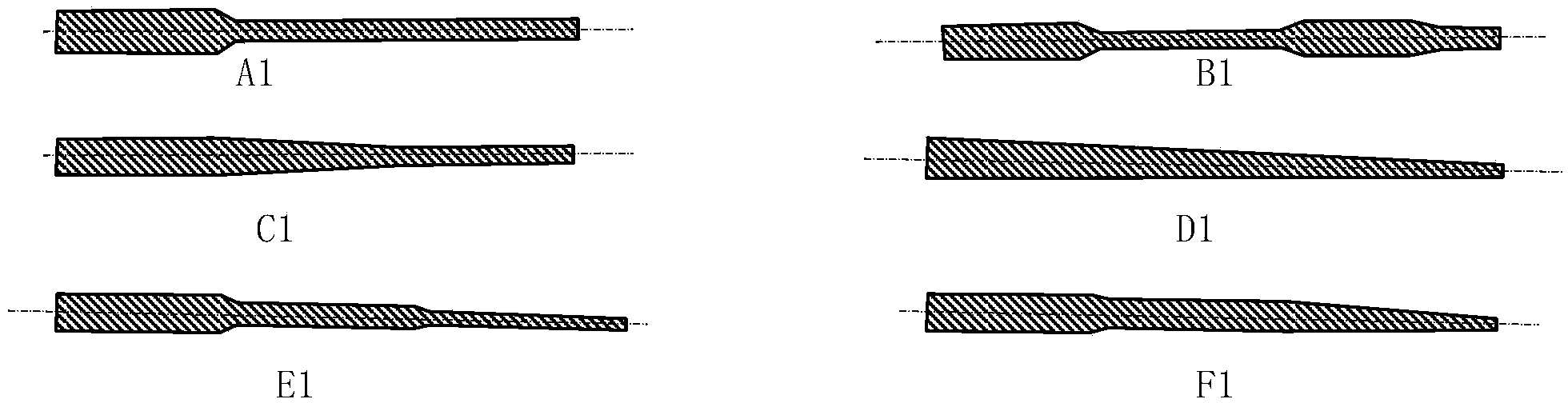

[0057] Six kinds of second rolling mills are used respectively, and the roll gap cross-section of the work roll gap structure is horizontal axis symmetric type; figure 1 As shown in A1, B1, C1, D1, E1 and F1; the middle plate strip with special-shaped structure in the middle is formed and rolled by the second rolling mill to make six kinds of transversely variable thickness plates and strips, and the structures are as follows figure 1 shown in A1, B1, C1, D1, E1 and F1;

[0058] Carry out band tension rolling in rolling process, method ...

Embodiment 3

[0066] The structure of the upper and lower work rolls of the first rolling mill adopted is the same as that of the second first rolling mill of embodiment 1, and the roll gap constitutes a horizontally placed S-shaped curve structure; system, making the middle plate strip with a special-shaped structure in the middle, and the special-shaped structure is a horizontally placed S-shaped curve structure;

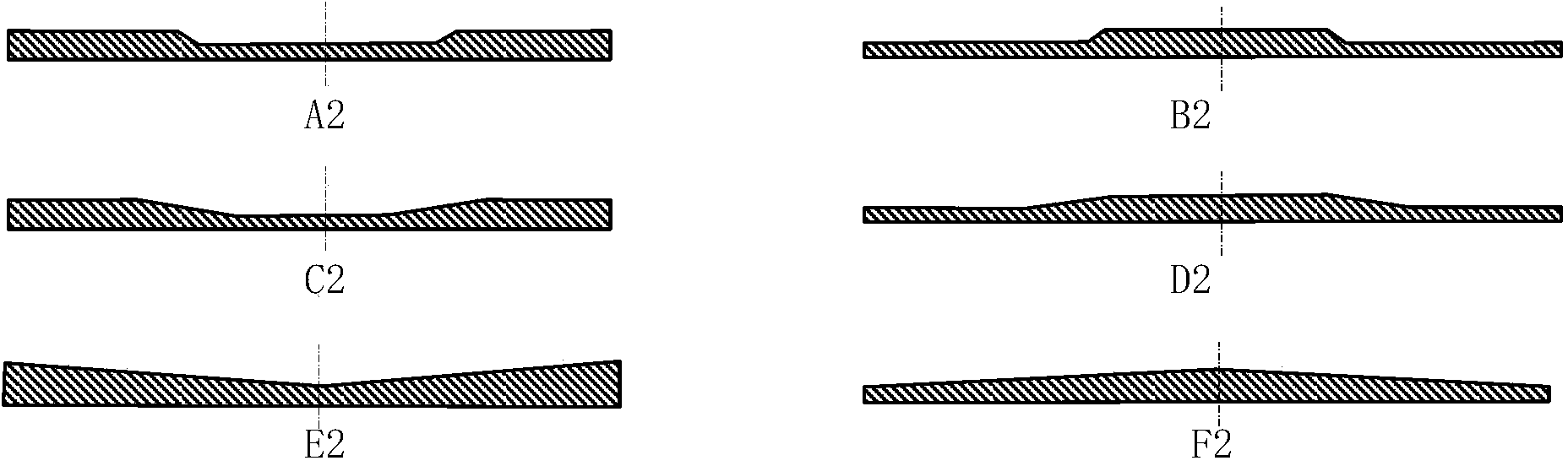

[0067] Six kinds of second rolling mills are used respectively, and the roll gap cross-section of the roll gap structure is vertical axis symmetric type; figure 2 Shown in A2, B2, C2, D2, E2 and F2 of A2, B2, C2, D2, E2 and F2; the middle plate and strip with special-shaped structure in the middle are formed and rolled by the second rolling mill to make six kinds of transversely variable thickness plates and strips, and the structures are as follows figure 2 shown in A2, B2, C2, D2, E2 and F2;

[0068] Carry out band tension rolling in rolling process, method is with embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com