Casting molding process for shell on mine crusher

A molding process and crusher technology, used in casting molding equipment, casting molds, casting mold components, etc., can solve the problem of difficult to ensure the uniform wall thickness of the shell on the crusher, the quality of the inner and outer surfaces, the dimensional accuracy of the blank outline, and the impact of casting quality. The service life of the equipment, it is difficult to ensure the wall thickness and dimensional accuracy, etc., to achieve the effect of shortening the production period, reducing the amount of post-processing, and ensuring the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

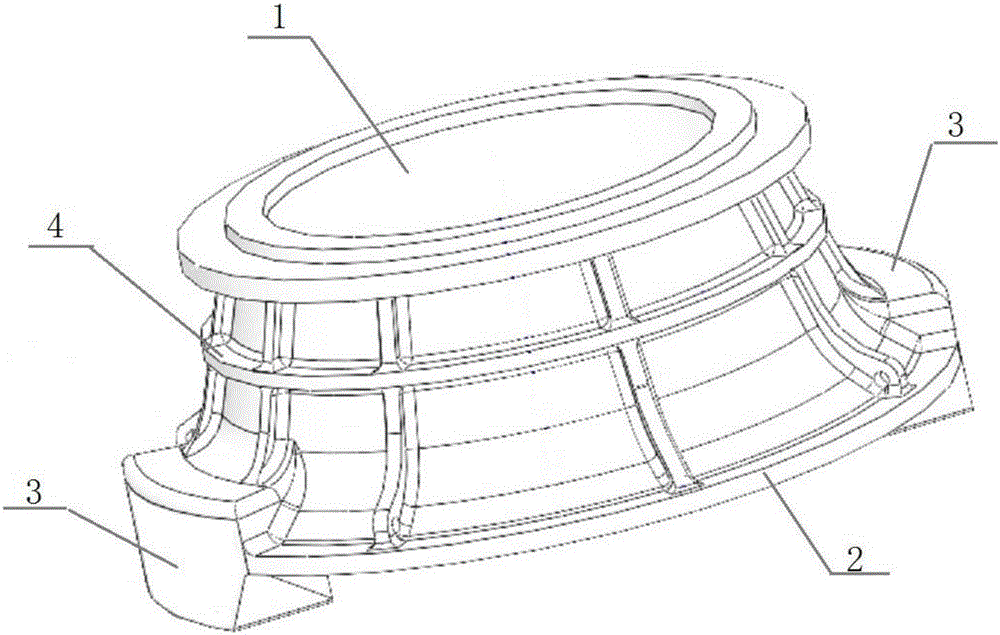

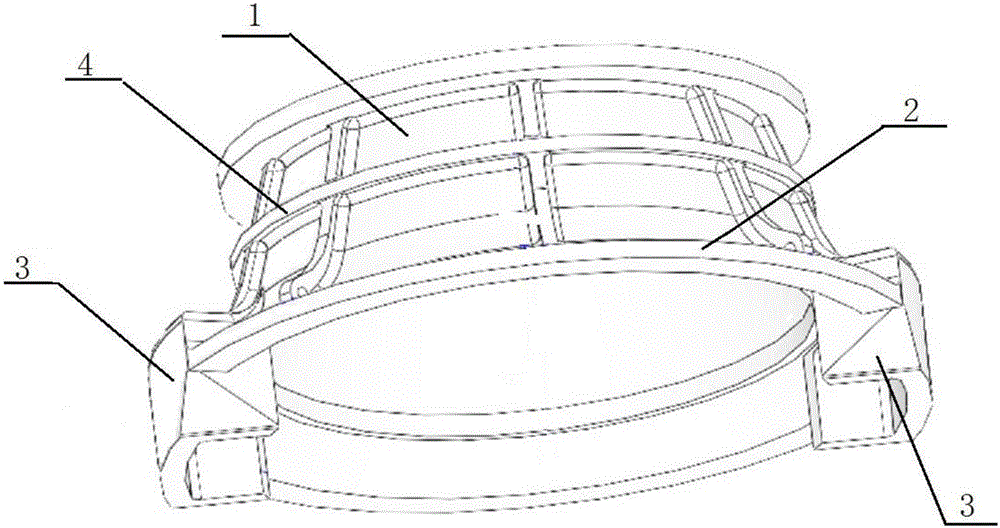

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0026] A casting molding process for the upper shell of a mine crusher according to the present invention, the main structure adopts a hollow solid sample molding; specifically, it includes the following steps:

[0027] 1) Make a hollow real sample; according to the shape of the scraper, use wooden boards to be stacked layer by layer, and make the width equal to the wall thickness of the casting 1, and fix firmly with glue and iron nails between each layer of wooden boards; the cross section is made as Circular hollow real sample;

[0028] 2) The ribs 4 and fillets outside the casting 1 are all made as loose blocks;

[0029] 3) The lower part of the hollow real sample corresponds to the height of the flange 2 at the bottom of the casting as a straight section, and a solid core head is arranged in the hollow real sample, and the solid core head is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com