Preparation method for graphene sponge reinforced nanofiber membrane

A nanofiber membrane, graphene sponge technology, applied in the direction of fiber type, fiber treatment, plant fiber, etc., can solve the problems of difficult to achieve polymorphic adhesion, difficult to guarantee penetration uniformity, etc., achieve good mechanical properties and toughness, size The effect of strong controllability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

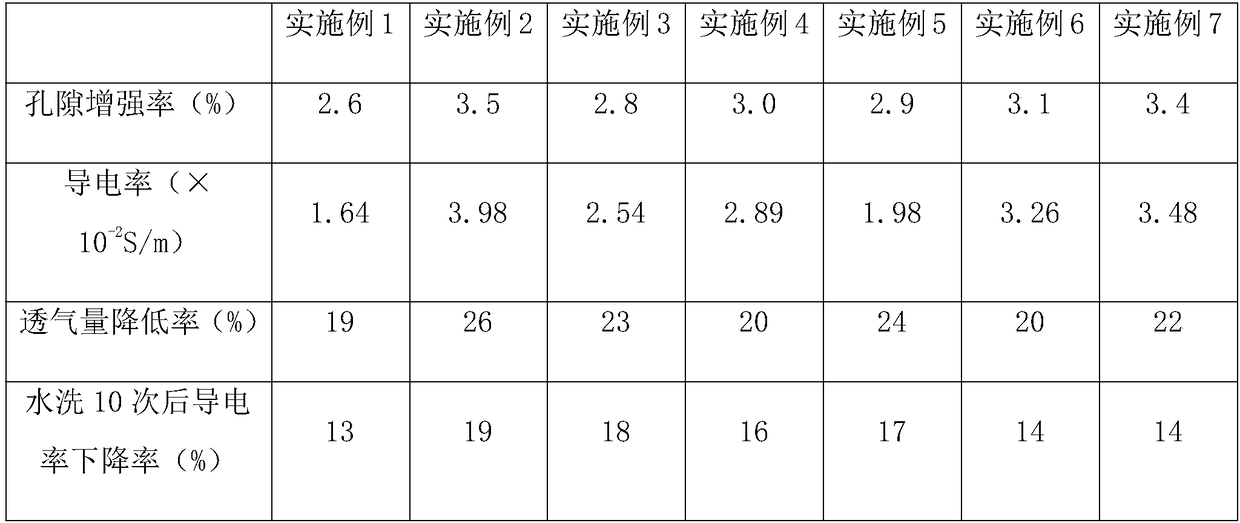

Examples

Embodiment 1

[0023] (1) Add the microemulsion containing titanium dioxide sol to the graphene oxide solution, stir at a high speed at 10000r / min until the mixture is uniform, and obtain a precursor solution with a graphene oxide content of 10wt%, and place the precursor solution in a low temperature environment Quick freezing and vacuum drying were carried out, and hydrogen was passed through for high-temperature reduction to obtain a graphene-based porous sponge with a pore size of 0.5 μm.

[0024] (2) After crushing and grinding the graphene-based porous sponge body to a particle size of 50 μm, disperse it in deionized water, and obtain an electrophoretic solution with a graphene-based porous sponge body content of 10 mg / mL after ultrasonic dispersion, and prepare it by electrospinning The regenerated cellulose nanofiber membrane is immersed in the electrophoretic solution, the positive and negative electrodes are inserted on both sides of the nanofiber membrane, the electrophoresis react...

Embodiment 2

[0026] (1) Add the microemulsion containing titanium dioxide sol to the graphene oxide solution, stir at a high speed at 20000r / min until the mixture is uniform, and obtain a precursor solution with a graphene oxide content of 30wt%, and place the precursor solution in a low temperature environment Quick freezing and vacuum drying were carried out, and hydrogen was passed through for high-temperature reduction to obtain a graphene-based porous sponge with a pore size of 3 μm.

[0027] (2) After crushing and grinding the graphene-based porous sponge body to a particle size of 100 μm, disperse it in deionized water, and obtain an electrophoretic solution with a graphene-based porous sponge body content of 25 mg / mL after ultrasonic dispersion, and prepare it by electrospinning The regenerated protein nanofiber membrane was immersed in the electrophoretic solution, the positive and negative electrodes were inserted on both sides of the nanofiber membrane, electrophoresis was perfor...

Embodiment 3

[0029] (1) Add the microemulsion containing titanium dioxide sol to the graphene oxide solution, stir at a high speed at 15000r / min until the mixture is uniform, and obtain a precursor solution with a graphene oxide content of 15wt%, and place the precursor solution in a low temperature environment Quick freezing and vacuum drying were carried out, and hydrogen was passed through for high-temperature reduction to obtain a graphene-based porous sponge with a pore size of 1.5 μm.

[0030] (2) After crushing and grinding the graphene-based porous sponge body to a particle size of 80 μm, disperse it in deionized water, and ultrasonically disperse to obtain an electrophoretic solution with a graphene-based porous sponge body content of 15 mg / mL, which is prepared by electrospinning The polylactic acid nanofiber membrane was immersed in the electrophoretic solution, the positive and negative electrodes were inserted on both sides of the nanofiber membrane, the electrophoresis reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com