Preparation method of gelatin methacrylamide core-shell microsphere based on microfluidics technique

A technology of gelatin methacrylamide and microfluidic technology, which is applied in the direction of microsphere preparation, microcapsule preparation, chemical instruments and methods, etc., can solve the problems of cumbersome methods, achieve good size controllability, uniform size, and system Uniform and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

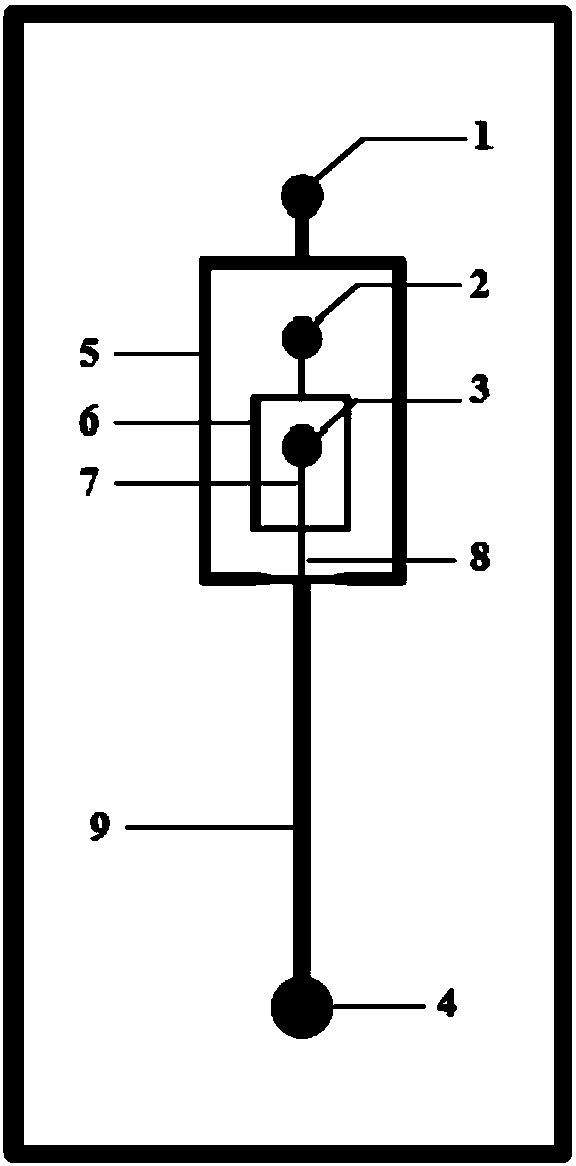

[0024] A kind of microfluidic chip of the present invention, such as figure 1 As shown, it is mainly composed of continuous phase inlet 1, shell fluid inlet 2, core fluid inlet 3, microsphere outlet 4, continuous phase channel 5, shell fluid channel 6, core fluid channel 7, laminar flow channel 8 and main channel 9;

[0025] The continuous phase inlet 1 is connected with the main channel 8 through the continuous phase channel 5, and the shell fluid inlet 2 and the core fluid inlet 3 are respectively connected with the laminar flow channel 8 and the main channel 9 through the shell fluid channel 6 and the core fluid channel 7;

[0026] In the microfluidic chip, the height and width of the continuous phase channel 5 are 310 μm and 270 μm respectively, the height and width of the shell fluid channel 6 are 150 μm and 150 μm respectively, the height and width of the core fluid channel 7 are 150 μm and 130 μm respectively, and the laminar flow channel The height and width of 8 are 1...

Embodiment 2

[0036] The present invention is a method for preparing gelatin methacrylamide core-shell microspheres based on microfluidic technology. The microfluidic chip is mainly composed of continuous phase inlet 1, shell fluid inlet 2, core fluid inlet 3, microsphere outlet 4, Composed of continuous phase channel 5, shell fluid channel 6, core fluid channel 7, laminar flow channel 8 and main channel 9;

[0037] The continuous phase inlet 1 is connected to the main channel 8 through the continuous phase channel 5, and the shell fluid inlet 2 and the core fluid inlet 3 are respectively connected to the laminar flow channel 8 and the main channel 9 through the shell fluid channel 6 and the core fluid channel 7;

[0038] In the microfluidic chip, the height and width of the continuous phase channel 5 are 310 μm and 270 μm respectively, the height and width of the shell fluid channel 6 are 150 μm and 150 μm respectively, the height and width of the core fluid channel 7 are 150 μm and 130 μm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com