Graphene-CBS composite pre-dispersed rubber master batch and preparation method for same

A technology of pre-dispersed masterbatch and graphene, applied in the field of graphene-CBS composite pre-dispersed masterbatch and its preparation, to achieve the effects of improved dispersibility, easy storage and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

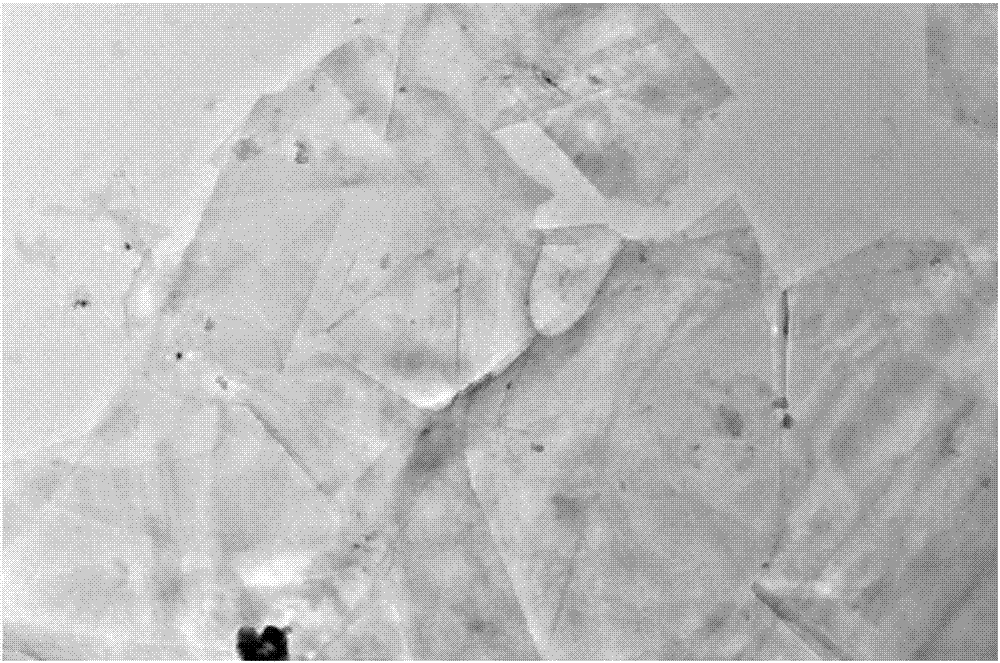

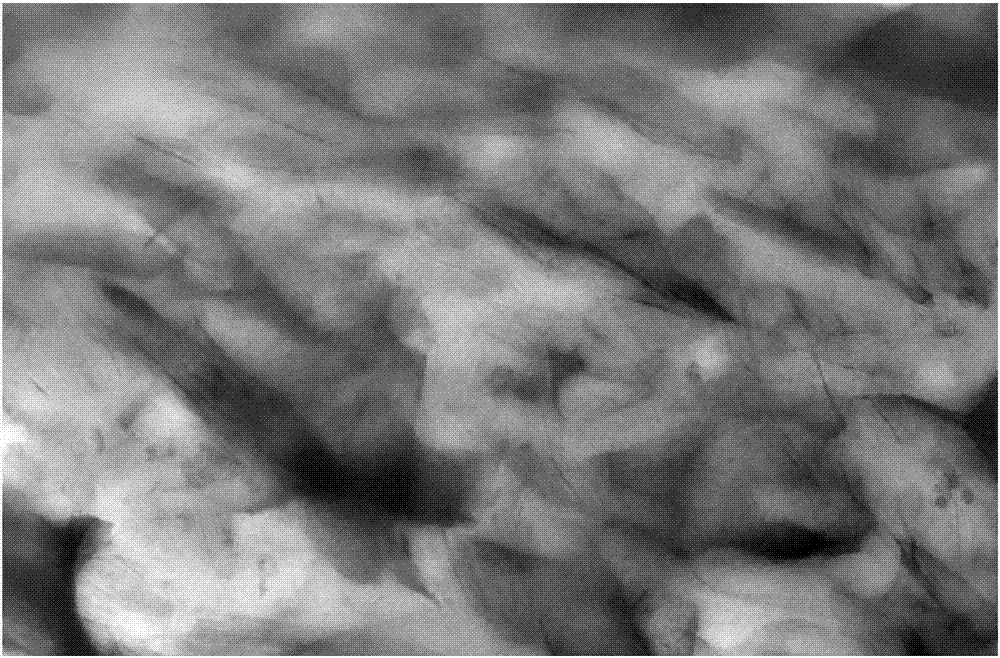

Image

Examples

Embodiment 1

[0025] The graphene pre-dispersed masterbatch of embodiment one, by weight, its percentage by weight consists of: graphene 40%, N-cyclohexyl-2-benzothiazole sulfenamide 30%, two-[γ- (triethoxysilane) propyl]-tetrasulfide 4%, EPDM rubber 9%, EVA resin 5%, triethanolamine 1%, wetting agent (saturated fatty acid) 2%, softener 9%, The softener is prepared from paraffin oil and aromatic oil in a weight ratio of 1:3. The preparation method of the pre-dispersed masterbatch comprises the following steps:

[0026] (1) Accurately weigh the raw materials required for the preparation of masterbatch according to the proportion;

[0027] (2) Divide the EVA resin into two parts; then put the EPDM rubber into the internal mixer and knead for 4 minutes; then add 1 / 2 of the EVA resin to the internal mixer and knead for 5 minutes; Then add 1 / 2 EVA resin to the internal mixer, mix until the temperature in the internal mixer rises to 85°C, remove the glue, and obtain the base rubber, and pass the...

Embodiment 2

[0031] The graphene predispersed master batch of embodiment two, by weight, its percentage by weight consists of: graphene 45%, N-cyclohexyl-2-benzothiazole sulfenamide 25%, two-[γ- (triethoxysilane) propyl]-tetrasulfide 3%, EPDM rubber 11%, EVA resin 4%, triethanolamine 1%, wetting agent (fatty acid soap) 3%, softener 8%, The softener is prepared from paraffin oil and aromatic oil at a weight ratio of 1:2. The preparation method of the pre-dispersed masterbatch comprises the following steps:

[0032] (1) Accurately weigh the raw materials required for the preparation of masterbatch according to the proportion;

[0033] (2) Divide the EVA resin into two parts; then put the EPDM rubber into the internal mixer and knead for 3 minutes; then add 1 / 2 of the EVA resin to the internal mixer and knead for 4 minutes; Then add 1 / 2 EVA resin to the internal mixer, mix until the temperature in the internal mixer rises to 85°C, discharge the glue, and obtain the base rubber, and pass the ba...

Embodiment 3

[0036] The graphene pre-dispersed masterbatch of embodiment three, by weight, its percentage by weight consists of: graphene 35%, N-cyclohexyl-2-benzothiazole sulfenamide 28%, two-[γ- (triethoxysilane) propyl]-tetrasulfide 6%, EPDM rubber 13%, EVA resin 3%, triethanolamine 3%, wetting agent (polyol ester) 2%, softener 10% , the softening agent is formulated with paraffin oil and aromatic hydrocarbon oil with a weight ratio of 2:5, and the preparation method of the pre-dispersed masterbatch comprises the following steps:

[0037] (1) Accurately weigh the raw materials required for the preparation of masterbatch according to the proportion;

[0038] (2) Divide the EVA resin into two parts; then put the EPDM rubber into the internal mixer and knead for 5 minutes; then add 1 / 2 of the EVA resin to the internal mixer and knead for 6 minutes; Then add 1 / 2 EVA resin to the internal mixer, mix until the temperature in the internal mixer rises to 85°C, discharge the glue, and obtain th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com