Catalytically cracked gasoline hydrodesulfurization catalyst and preparation method thereof

A catalyst and compound technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as the use of toxic hydrogen sulfide gas, large environmental pollution, complex processes, etc., and improve hydrodesulfurization Selectivity, good particle size controllability, uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

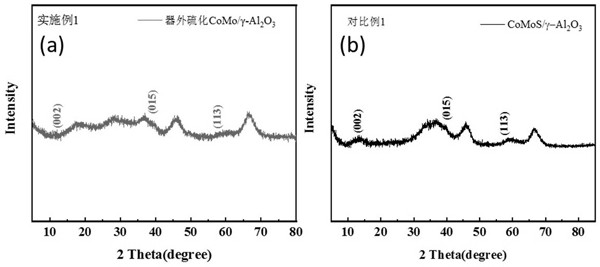

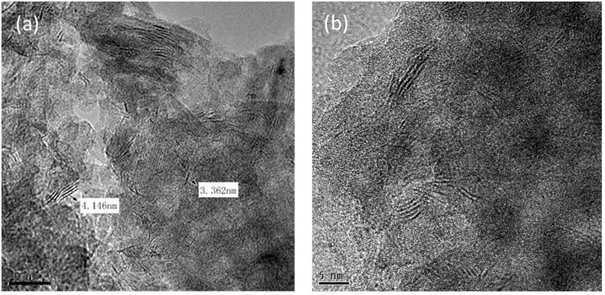

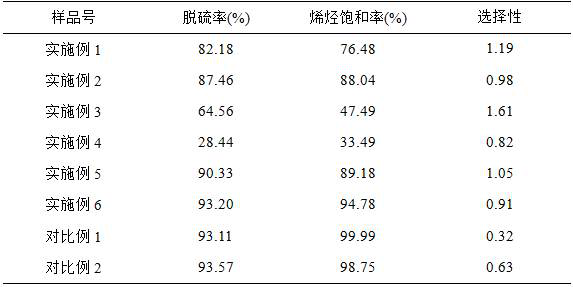

Embodiment 1

[0026] Mix 100 g pseudo-boehmite, 4.0 g field green powder, 5.0 g HNO 3 and 75 g of deionized water were put into a kneader and kneaded into a block, then put into an extruder, extruded using a clover template with a diameter of 2.0 mm, and then dried at a temperature of 65°C for 4 h, and then dried at a temperature of 500°C Calcined under the condition of 4 h to get Al 2 o 3 carrier.

[0027] According to 3wt%Co 3 o 4 content, a certain amount of cobalt acetate was dissolved in 70 mL of ammonia water to prepare a solution, which was impregnated in Al by equal volume method 2 o 3 supported, aged for 12 h, dried at 65°C for 4 h, and calcined at 500°C for 4 h to obtain Co 3 o 4 / γ-Al 2 o 3 Precursor.

[0028] According to 12wt%MoO 3 content and the molar ratio of S:Mo=4:1, dissolving ammonium heptamolybdate in an appropriate amount of ammonia water, then adding a certain amount of ammonium sulfide solution with a concentration of 20%, and reacting at 100°C for 1.0 h, ...

Embodiment 2

[0032] The preparation process is the same as in Example 1, and what is different from Example 1 is that the sulfur-containing compound is changed from ammonium sulfide to diethyl tetrasulfide; the synthesis temperature of ammonium tetrathiomolybdate is increased from 100°C to 130°C; The steaming temperature was reduced from 65°C to 60°C.

Embodiment 3

[0034] The preparation process was the same as in Example 1, except that the preparation temperature of ammonium tetrathiomolybdate was reduced from 100°C to 80°C, and the rotary evaporation temperature was reduced from 65°C to 55°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com