Preparation method of aluminum-doped cobaltosic oxide particles

A technology of cobalt tetroxide particles and aluminum doping, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., which can solve the problems of poor distribution uniformity of aluminum elements, poor aluminum uniformity, and strict requirements on process parameters, so as to achieve high uniformity and reduce losses , good effect of size controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

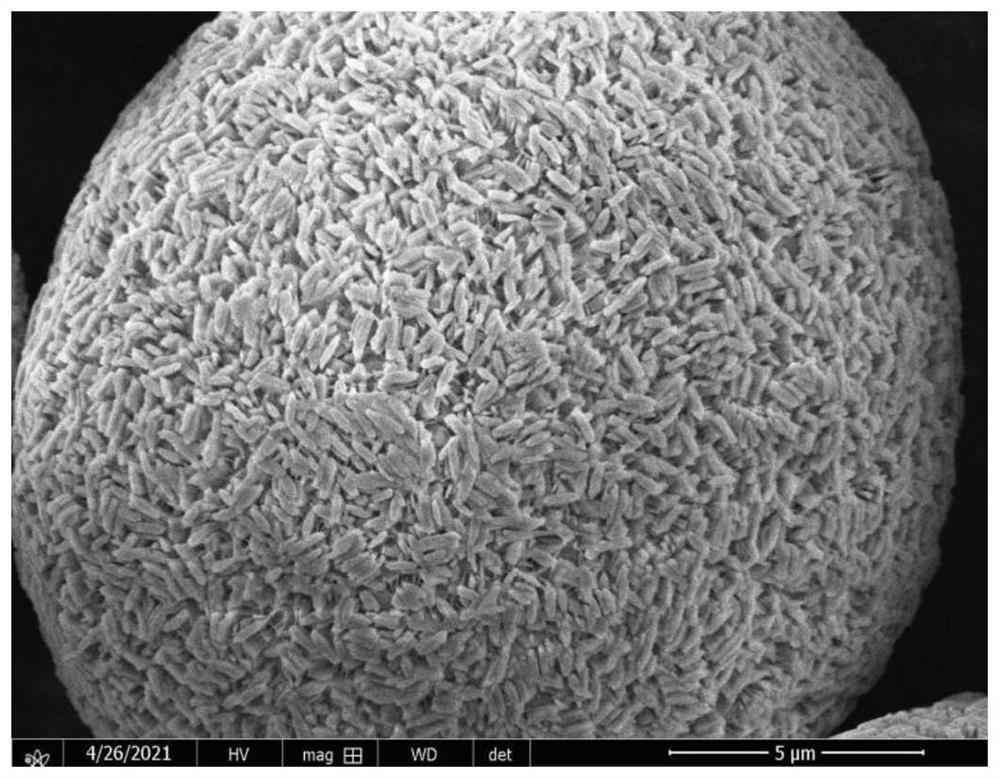

Embodiment 1

[0031] (1) preparation Co concentration is the cobalt salt solution of 110g / L;

[0032] (2) Prepare a sodium metaaluminate solution with an Al concentration of 3g / L: measure a certain amount of aluminum sulfate solid and add an appropriate amount of hot water to dissolve it. After the solid is completely dissolved, slowly add a certain amount of liquid caustic soda to keep the liquid caustic and aluminum sulfate The molar ratio is 12:1;

[0033] (3) prepare the ammonium bicarbonate solution of 220g / L;

[0034] (4) Add 25g / L ammonium bicarbonate solution to the 50L reactor until the first layer is stirred, and mix 110g / L cobalt salt solution, 3g / L aluminum salt solution and 220g / L ammonium bicarbonate solution with 2L The flow rate of / h, 1L / h, 4L / h is added to the 50L reactor in parallel. The starting conditions in the reactor are: temperature 42°C, rotation speed 770rpm, clarification process, process pH control of 7.1±0.1, growth rate control of 0.08 -0.1um / h, until the re...

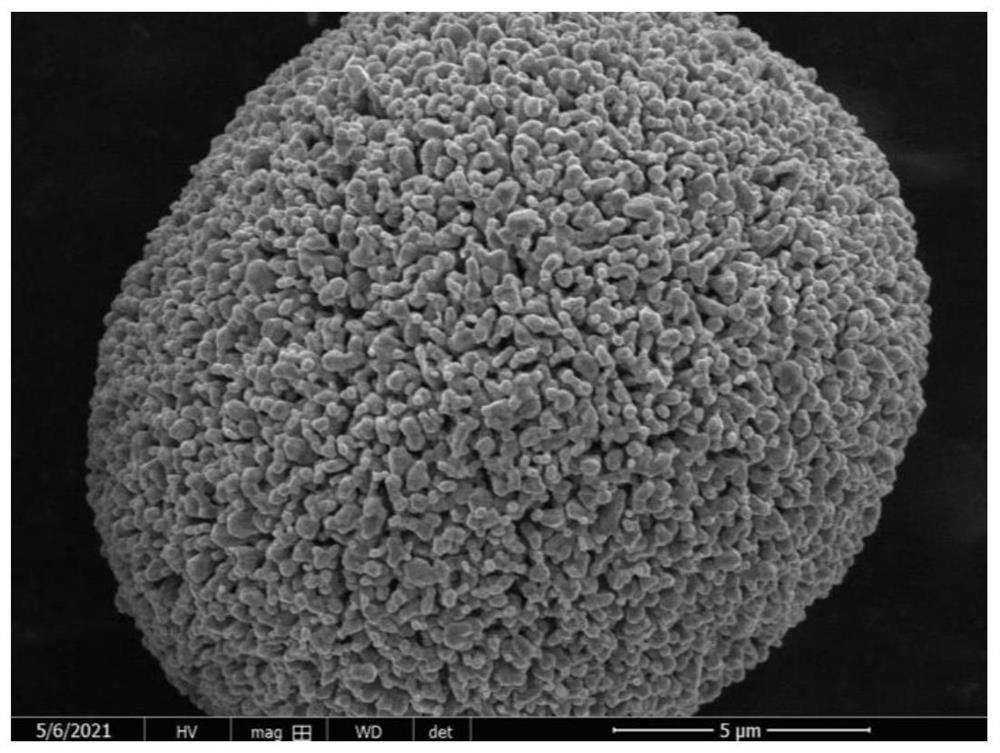

Embodiment 2

[0037] (1) preparation Co concentration is the cobalt salt solution of 130g / L;

[0038] (2) Prepare a sodium metaaluminate solution with an Al concentration of 4g / L: measure a certain amount of aluminum sulfate solid and add an appropriate amount of hot water to dissolve it. After the solid is completely dissolved, slowly add a certain amount of liquid caustic soda to keep the liquid caustic soda and aluminum sulfate The molar ratio is 10:1;

[0039] (3) prepare the ammonium bicarbonate solution of 220g / L;

[0040] (4) Add 10g / L ammonium bicarbonate solution to the 50L reactor until the first layer is stirred, and mix 130g / L cobalt salt solution, 4g / L aluminum salt solution and 220g / L ammonium bicarbonate solution with 3L Flow rates of / h, 1.5L / h, and 7.5L / h are fed into a 50L reactor in parallel. The starting conditions in the reactor are: temperature 50°C, rotation speed 600rpm, clarification process, process pH control of 7.3±0.1, growth rate control 0.08-0.1um / h, until t...

Embodiment 3

[0043] (1) preparation Co concentration is the cobalt salt solution of 130g / L;

[0044] (2) Prepare a sodium metaaluminate solution with an Al concentration of 3g / L: measure a certain amount of aluminum sulfate solid and add an appropriate amount of hot water to dissolve it. After the solid is completely dissolved, slowly add a certain amount of liquid caustic soda to keep the liquid caustic and aluminum sulfate The molar ratio is 18:1;

[0045] (3) prepare the ammonium bicarbonate solution of 210g / L;

[0046] (4) Add 12L of pure water bottom liquid to the 50L reaction kettle to stir in the first layer, mix 130g / L cobalt salt solution, 3g / L aluminum salt solution and 210g / L ammonium bicarbonate solution at 2L / L The flow rates of h, 1L / h, and 4.3L / h are fed into a 50L reactor in parallel. The starting conditions in the reactor are: temperature 60°C, rotation speed 700rpm, clarification process, process pH control of 7.2±0.1, growth rate control of 0.08- 0.1um / h, until the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com