Big round bloom water jacket casted with high precision

A high-precision and precise technology, applied in casting molding equipment, casting mold, casting mold composition, etc., can solve the problem of uneven water jacket of large round billet mold and water gap of copper tube, and inaccurate positioning accuracy of water jacket arc centerline , dimensional accuracy can not fully meet the requirements and other problems, to achieve the effect of strong dimensional controllability, increased rigidity, and enhanced rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

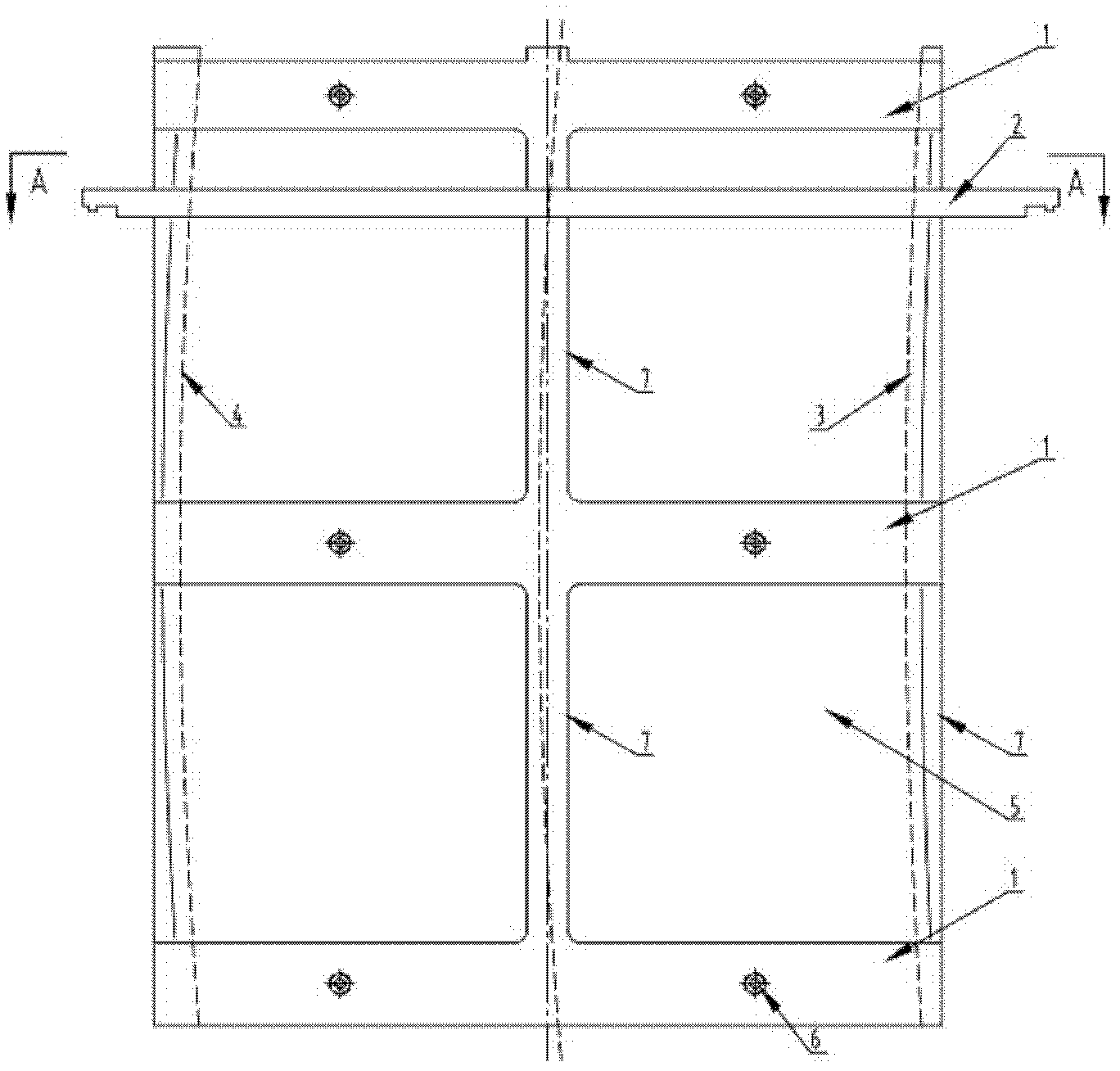

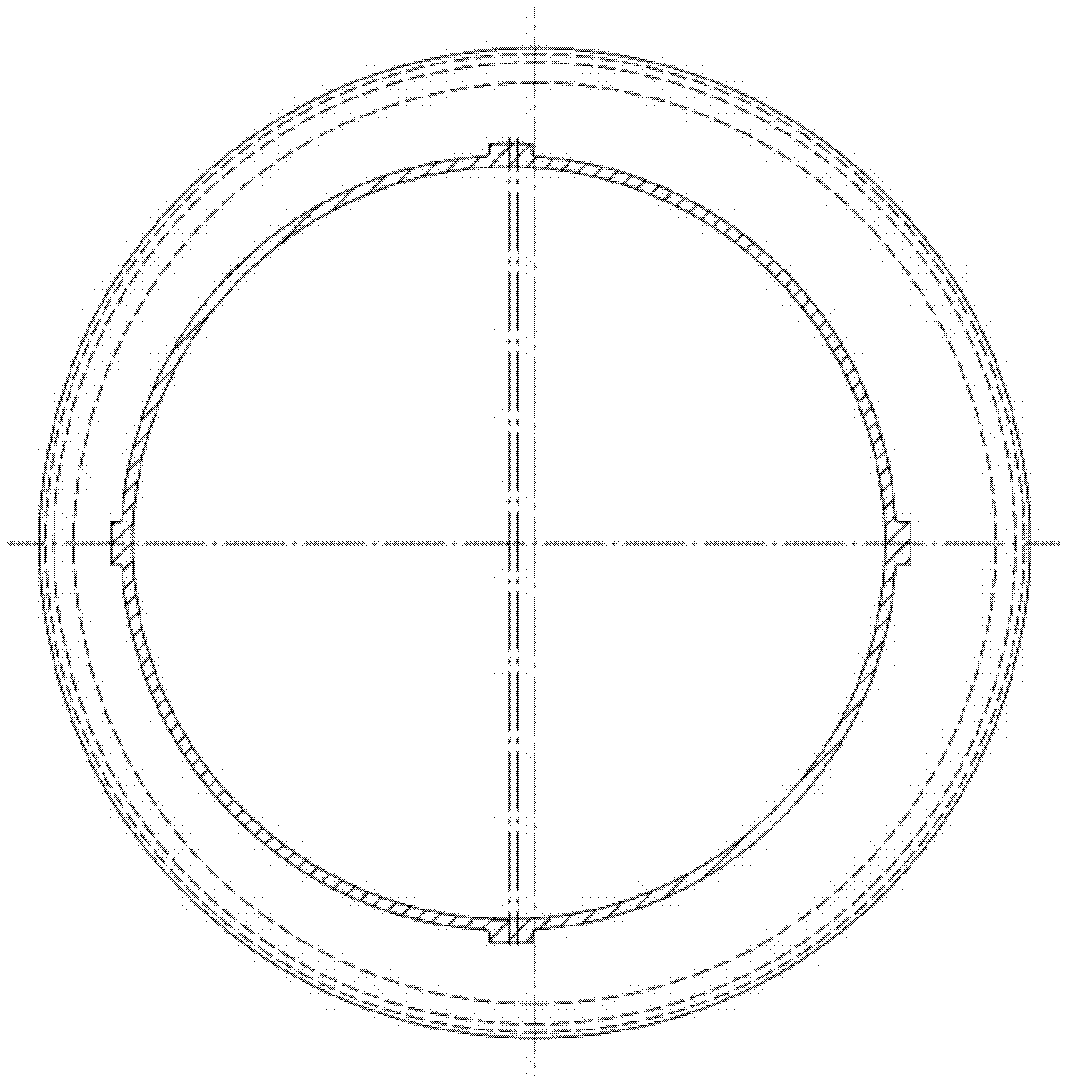

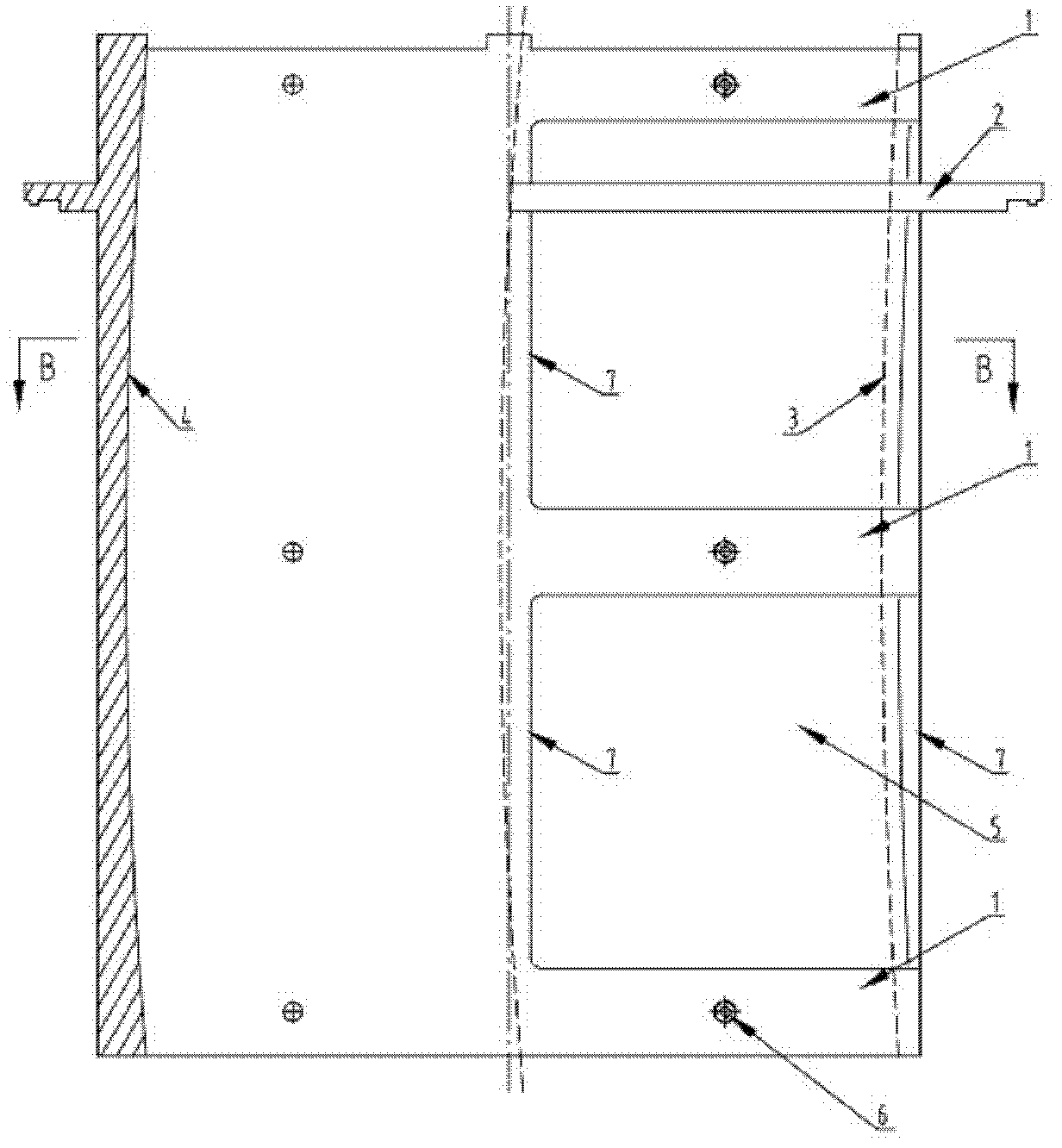

[0021] Marks in the accompanying drawings: 1-annular flange reinforcing rib, 2-flange, 3-inner arc, 4-outer arc, 5-water sleeve body, 6-adjusting bolt, 7-vertical flange reinforcing rib.

[0022] Embodiments of the invention will be further described below in conjunction with the accompanying drawings:

[0023] Refer to attached Figure 1-7 , in the embodiment of the present invention, the large round billet water jacket of precision high-precision casting adopts the resin casting casting stainless steel molding process, and the stainless steel water jacket sleeve body 5, the positioning flange 2, and the annular flange reinforcement rib 1 on the outer circle of the water jacket 1. The vertical flange reinforcement 7 is directly poured and formed by the precision casting method. The flange reinforcement (1, 7) on the water jacket, the flange 2 and the cylinder body 5 are a whole, which are casted from stainless steel castings. The inner arc 3 and outer arc 4 of the water jack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com