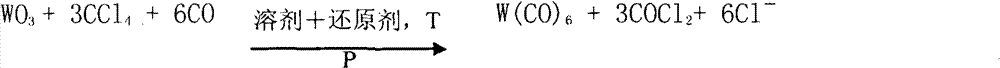

Method for directly synthesizing metal (tungsten or molybdenum) carbonyl complex from tungsten oxide or molybdenum oxide

A metal carbonyl and oxide technology, applied in the field of powder metallurgy, can solve problems such as harsh reaction conditions, low synthesis efficiency, and complicated process, and achieve the effects of mild synthesis conditions, easy operation, and high synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

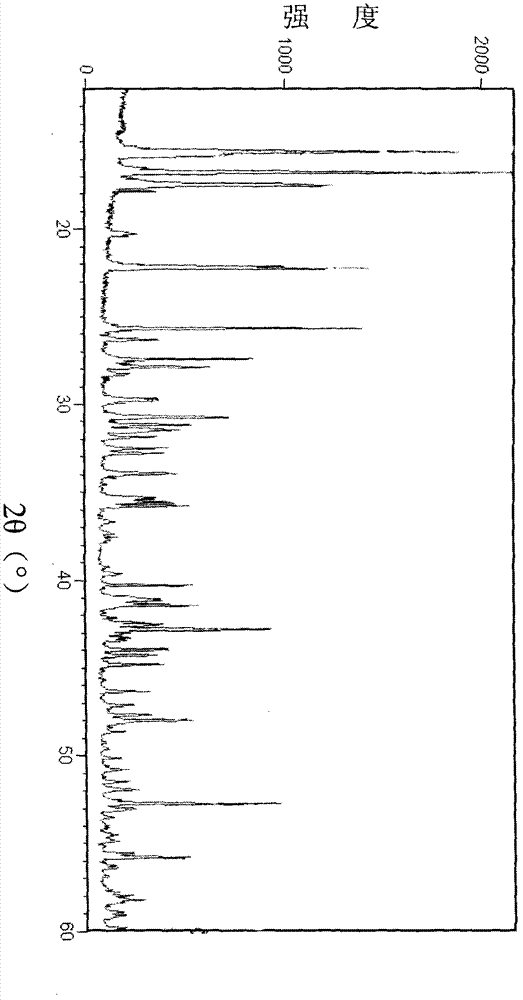

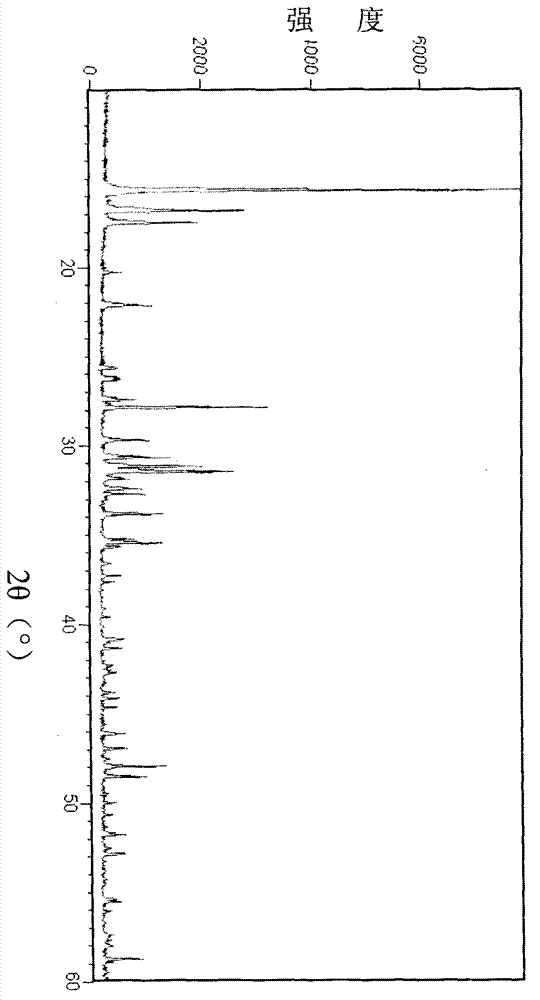

Embodiment 1

[0021] First add 60g of tungsten trioxide, 100ml of carbon tetrachloride, 2030ml of anhydrous acetone, 180g of independently packaged iron powder (60g) and a reducing agent mixed with iron pentacarbonyl (120g) in a mass ratio of 1:2 (mass The percentages are 3%, 8%, 80%, 9% successively); 2MPa carbon monoxide is charged and discharged 3 times in the reactor to replace the air in the reaction system and removed, then the reactor is heated to 200°C and kept for 4 hours; the reaction system After cooling down to 30°C, feed carbon monoxide to 8MPa and maintain the pressure, then turn on the stirring device of the reactor, break the packaged reducing agent container, the stirrer rotates at 100 rpm, and continue the reaction for 1 hour; after the reaction is completed, the solution is cooled to room temperature Finally, the reaction solution was taken out, and 10.9 g of colorless crystals of tungsten hexacarbonyl were obtained by distillation and heating sublimation, and the product ...

Embodiment 2

[0023] First add 60g of tungsten trioxide, 85ml of carbon tetrachloride, 1580ml of anhydrous ether, 180g of independently packaged zinc powder (60g) and nickel tetracarbonyl (120g) in a 1:2 mass ratio mixed reducing agent (mass The percentages are 4%, 9%, 75%, 12% successively); 2MPa carbon monoxide is charged and discharged 3 times in the reactor to replace the air in the reaction system and removed, then the reactor is heated to 220°C and kept for 6 hours; the reaction system After cooling down to 40°C, feed carbon monoxide to 10MPa and keep the pressure, then turn on the stirring device of the reactor, break the packaged reducing agent container, the stirrer rotates at 150 rpm, and continue the reaction for 6 hours; after the reaction is completed, the solution is cooled to room temperature Finally, the reaction solution was taken out, and 24.6 g of colorless crystals of tungsten hexacarbonyl were obtained by distillation and heating sublimation, and the product yield was ab...

Embodiment 3

[0025] First add 80g of tungsten trioxide, 100ml of carbon tetrachloride, 1570ml of anhydrous ether, 240g of independently packaged aluminum powder (80g) and a reducing agent mixed with iron pentacarbonyl (160g) in a mass ratio of 1:2 (mass The percentages are 5%, 10%, 70%, 15% successively); 2MPa carbon monoxide is charged and discharged 3 times in the reactor to replace the air in the reaction system and removed, then the reactor is heated to 250°C and kept for 8 hours; the reaction system After cooling down to 50°C, feed carbon monoxide to 20MPa and keep the pressure, then turn on the stirring device of the reactor, break the packaged reducing agent container, the stirrer speed is 200 rpm, and continue the reaction for 12 hours; after the reaction is completed, the solution is cooled to room temperature Finally, the reaction solution was taken out, and 55.8 g of colorless crystals of tungsten hexacarbonyl were obtained by distillation and heating sublimation, and the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com