Method for one-step preparing of molybdenum disulfide film with ultra-lubricating function through atomic layer deposition and product and application of molybdenum disulfide film

A technology of atomic layer deposition and molybdenum disulfide, applied in coating, gaseous chemical plating, metal material coating process, etc., can solve problems such as complicated steps, shorten time and simplify the overall preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

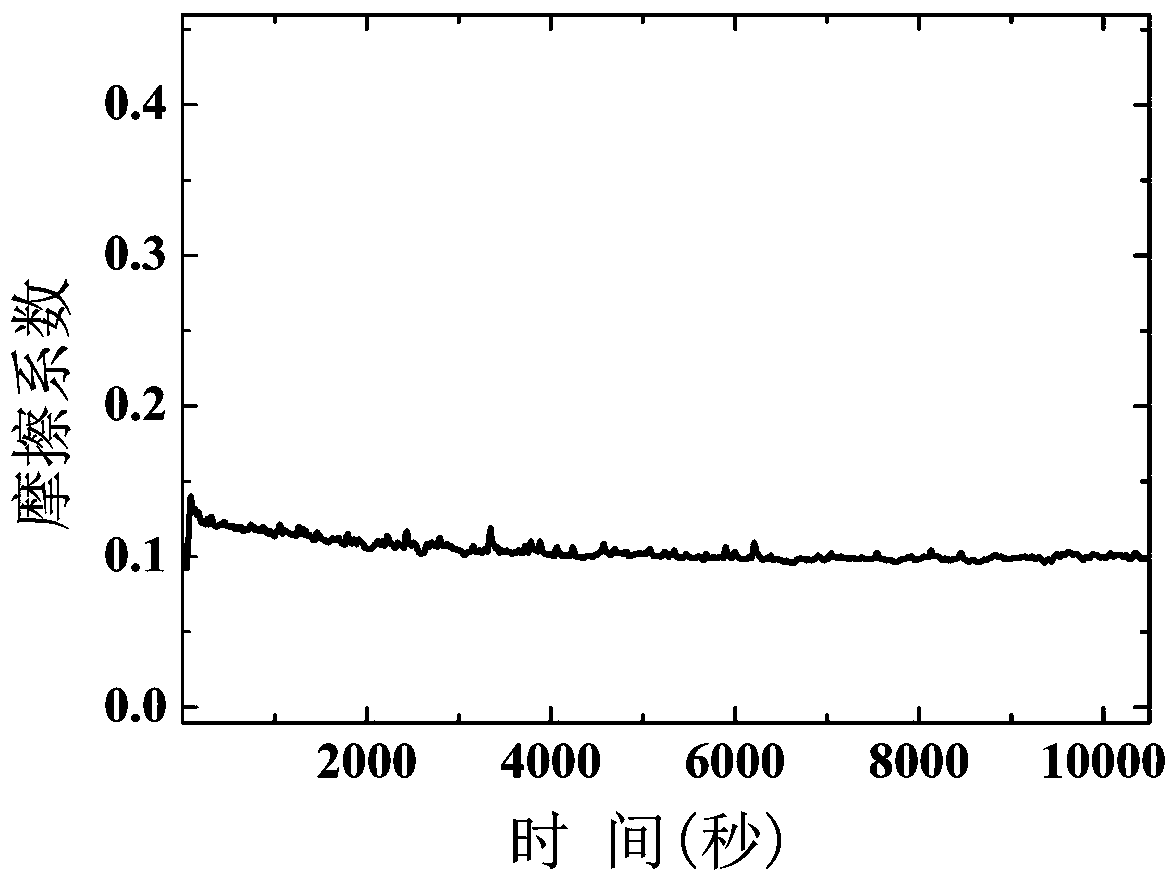

Embodiment 1

[0027] Put the Si which has been strictly cleaned on the surface as the substrate, put it into the ALD deposition chamber, heat it to 400°C, set the Mo(CO) 6 The heating temperature of (molybdenum hexacarbonyl) solid source is 35 ℃, the pulse time is 2 seconds, the flushing time is 5 seconds, and the carrier gas flow rate is 200 sccm; SH(CH 2 ) 2 The pulse time of the SH (ethanedithiol) source is 0.5 seconds, the flushing time is 5 seconds, and the carrier gas flow rate is 200 sccm; according to Mo(CO) 6 (Molybdenum hexacarbonyl) pulse / high-purity nitrogen purge / Mo(CO) 6 (Molybdenum hexacarbonyl) pulse / high purity nitrogen purge / SH(CH 2 ) 2 SH (ethanedithiol) pulse / high-purity nitrogen purge = (2s / 5s / 2s / 5s / 0.5s / 5s) is a cycle unit, and the number of deposition cycles is 100: MoS with excellent lubricating effect can be obtained 2 film.

Embodiment 2

[0029] Put the Si which has been strictly cleaned on the surface as the substrate, put it into the ALD deposition chamber, heat it to 350°C, set the Mo(CO) 6 (molybdenum hexacarbonyl) solid source heating temperature to 30 ℃, pulse time is 1.5 seconds, flushing time is 3 seconds, carrier gas flow is 150sccm; SH (CH 2 ) 2 The pulse time of the SH (ethanedithiol) source is 0.5 seconds, the flushing time is 5 seconds, and the carrier gas flow rate is 200 sccm; according to Mo(CO) 6 (Molybdenum hexacarbonyl) pulse / high-purity nitrogen purge / Mo(CO) 6 (Molybdenum hexacarbonyl) pulse / high purity nitrogen purge / SH(CH 2 ) 2SH (ethanedithiol) pulse / high-purity nitrogen purge = (1.5s / 3s / 1.5s / 3s / 0.5s / 5s) is a cycle unit, and the number of deposition cycles is 100; excellent lubricating effect can be obtained MoS 2 film.

Embodiment 3

[0031] Put the Si which has been strictly cleaned on the surface as the substrate, put it into the ALD deposition chamber, heat it to 450°C, set the Mo(CO) 6 (molybdenum hexacarbonyl) solid source heating temperature to 40 ℃, pulse time is 1.5 seconds, flushing time is 4 seconds, carrier gas flow is 200sccm; SH (CH 2 ) 2 The pulse time of the SH (ethanedithiol) source is 0.5 seconds, the flushing time is 5 seconds, and the carrier gas flow rate is 200 sccm; according to Mo(CO) 6 (Molybdenum hexacarbonyl) pulse / high-purity nitrogen purge / Mo(CO) 6 (Molybdenum hexacarbonyl) pulse / high purity nitrogen purge / SH(CH 2 ) 2 SH (ethanedithiol) pulse / high-purity nitrogen purge = (1.5s / 4s / 1.5s / 4s / 0.5s / 5s) is a cycle unit, and the number of deposition cycles is 100: excellent lubricating effect can be obtained MoS 2 film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com