Three-layer co-extrusion outer shielding peelable material for rubber sleeve cable and preparation method of three-layer co-extrusion outer shielding peelable material

A technology of three-layer co-extrusion and stripping materials, which is used in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, chemical instruments and methods, etc. The problem of lack of tensile properties and anti-oxidation properties can achieve the effect of prolonging the service life and improving the anti-oxidation properties and tensile properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

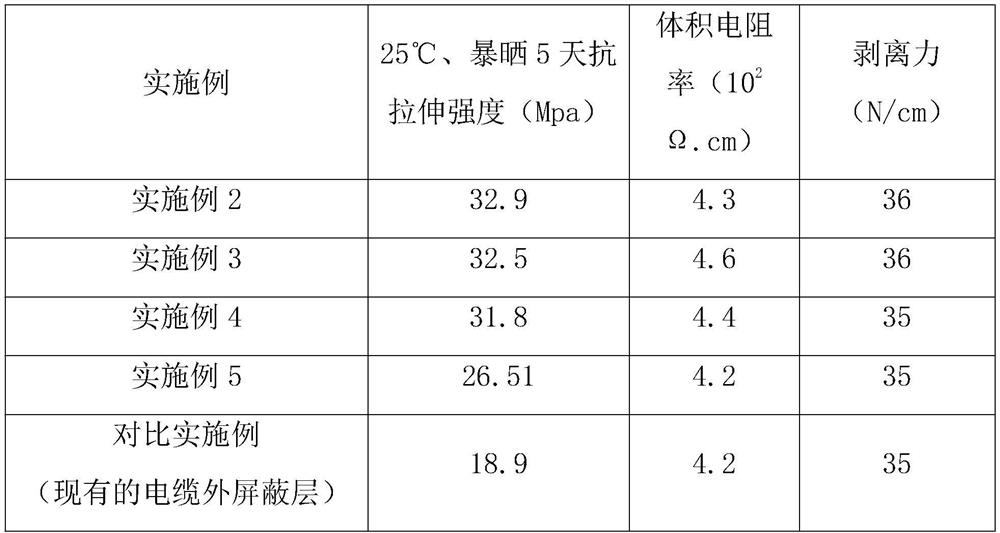

Examples

Embodiment 1

[0028] In this embodiment, the preparation method of the conductive carbon black modified by aromatic hydrocarbon radicals is specifically: heating 10 kg of conductive carbon black to 120° C. in an oxygen-free environment, and then adding 2.5 kg of aromatic carbon black to the heated conductive carbon black Hydrocarbon radicals are then reacted in a closed manner for 40 minutes to obtain conductive carbon black modified by aromatic hydrocarbon radicals.

Embodiment 2

[0030] The present embodiment carries out the preparation method of the three-layer co-extruded outer shielding strippable material of the rubber sheathed cable, adopts each raw material of Example 2 in Table 1, and includes the following steps:

[0031] S1. Disperse the conductive carbon black modified by aromatic hydrocarbon radicals in an ethanol solution, then add trichloroacetyl isocyanate, react under the action of ultrasonic vibration for 1 hour, then add molybdenum hexacarbonyl, and then react under the action of ultrasonic vibration for 1 hour to obtain the first reaction solution;

[0032] S2, add vinyl chloride monomer in the first reaction solution again, pass electric current into the first reaction solution, specifically: when passing electric current in the first reaction solution, insert a cathode plate and a piece of cathode plate into the first reaction solution Anode plate, the voltage connected between the cathode plate and the anode plate is 24V, the dista...

Embodiment 3

[0038] The present embodiment carries out the preparation method of the three-layer co-extruded outer shielding strippable material of the rubber sheathed cable, adopts each raw material of Example 3 in Table 1, and includes the following steps:

[0039] S1. Disperse the conductive carbon black modified by aromatic hydrocarbon radicals in ethanol solution, then add trichloroacetyl isocyanate, react under the action of ultrasonic vibration for 1.5h, then add molybdenum hexacarbonyl, and then react under the action of ultrasonic vibration for 1.5h , obtain the first reaction solution;

[0040] S2, add vinyl chloride monomer in the first reaction solution, pass electric current into the first reaction solution, specifically: when electric current is passed into the first reaction solution, insert a cathode plate and a cathode plate into the first reaction solution Anode plate, the voltage connected between the cathode plate and the anode plate is 30V, the distance between the cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com